Photosensitive drum drive assembly, photosensitive drum and processing cartridge

A technology of photosensitive drum driving and photosensitive drum, which is applied in the fields of optics, electrography, instruments, etc., can solve the problem of increasing the driving force, affecting the service accuracy and life of the axis of the photosensitive drum driving component with 4 round holes on the side wall, and affecting the imaging equipment Drive force output head 8 life and other issues, to avoid friction, simple and practical structure, improve the use of precision and life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

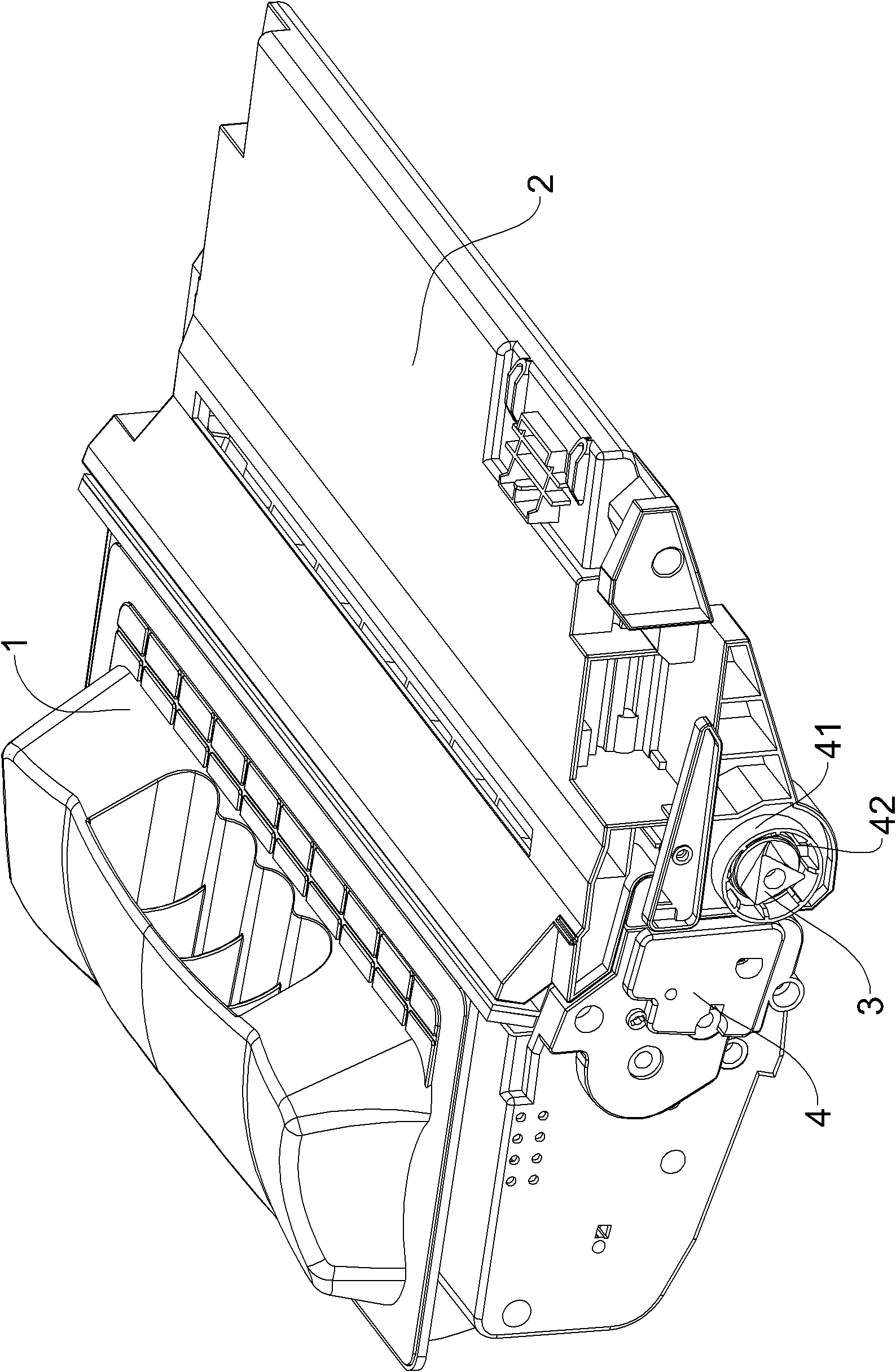

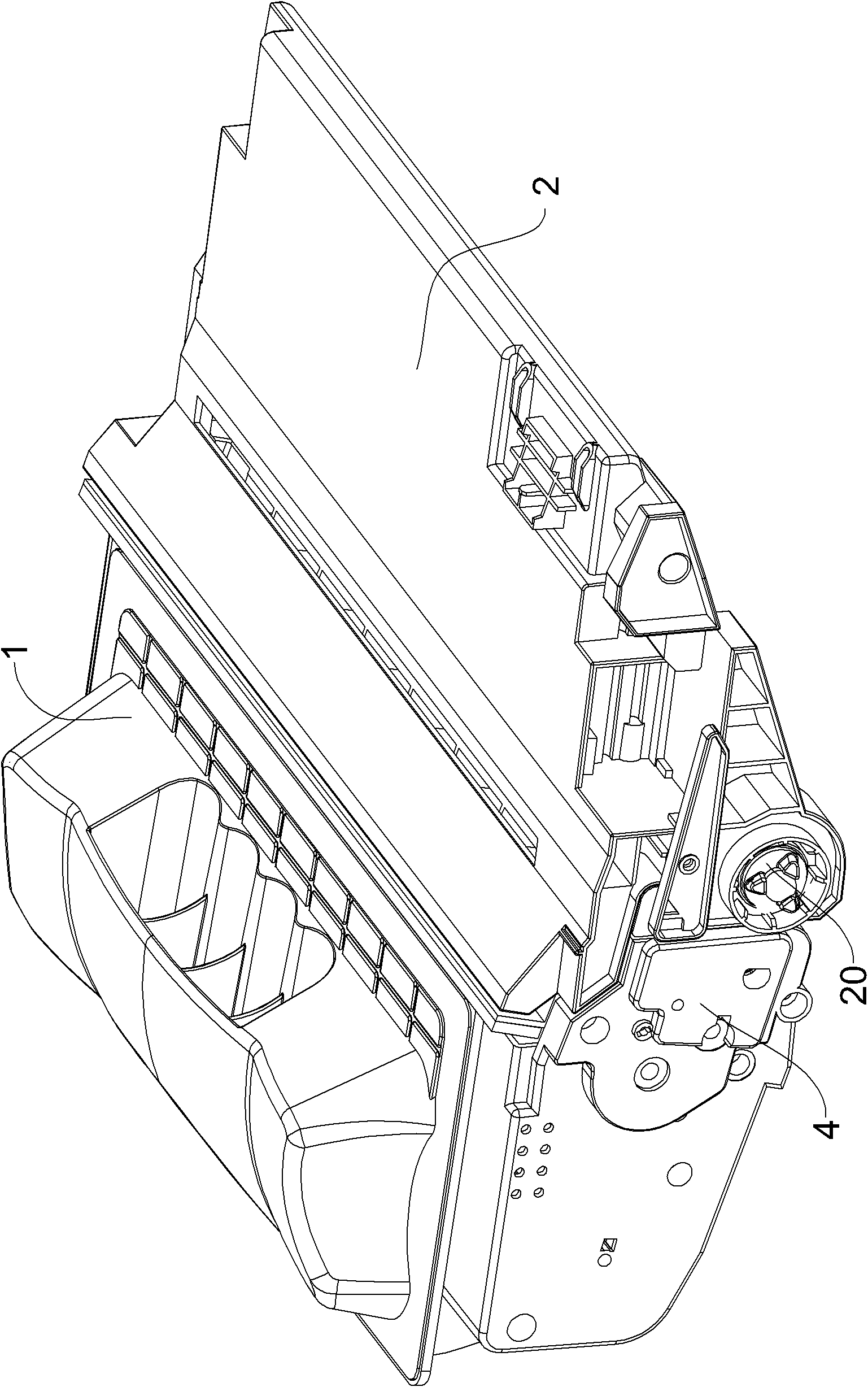

[0029] image 3 It shows a process box applied to imaging equipment according to the present invention. The composition and structure of the process box are roughly the same as those of the traditional process box. It mainly includes a powder bin 1 for containing carbon powder and a waste toner bin 2 for collecting waste powder. The toner bin 1 is provided with components such as a stirring frame, a powder feeding roller, and a developing roller; the waste toner bin 2 is provided with components such as a photosensitive drum 20 , a charging roller, and a cleaning blade. The toner bin 1 and the waste toner bin 2 are connected together by pins or other means. In order to clarify the problem, in each figure of the following embodiments, the driving force output mechanism of the imaging device that does not belong to the present invention is indicated by a two-dot dash line, and the same reference numerals in each figure indicate the same structure.

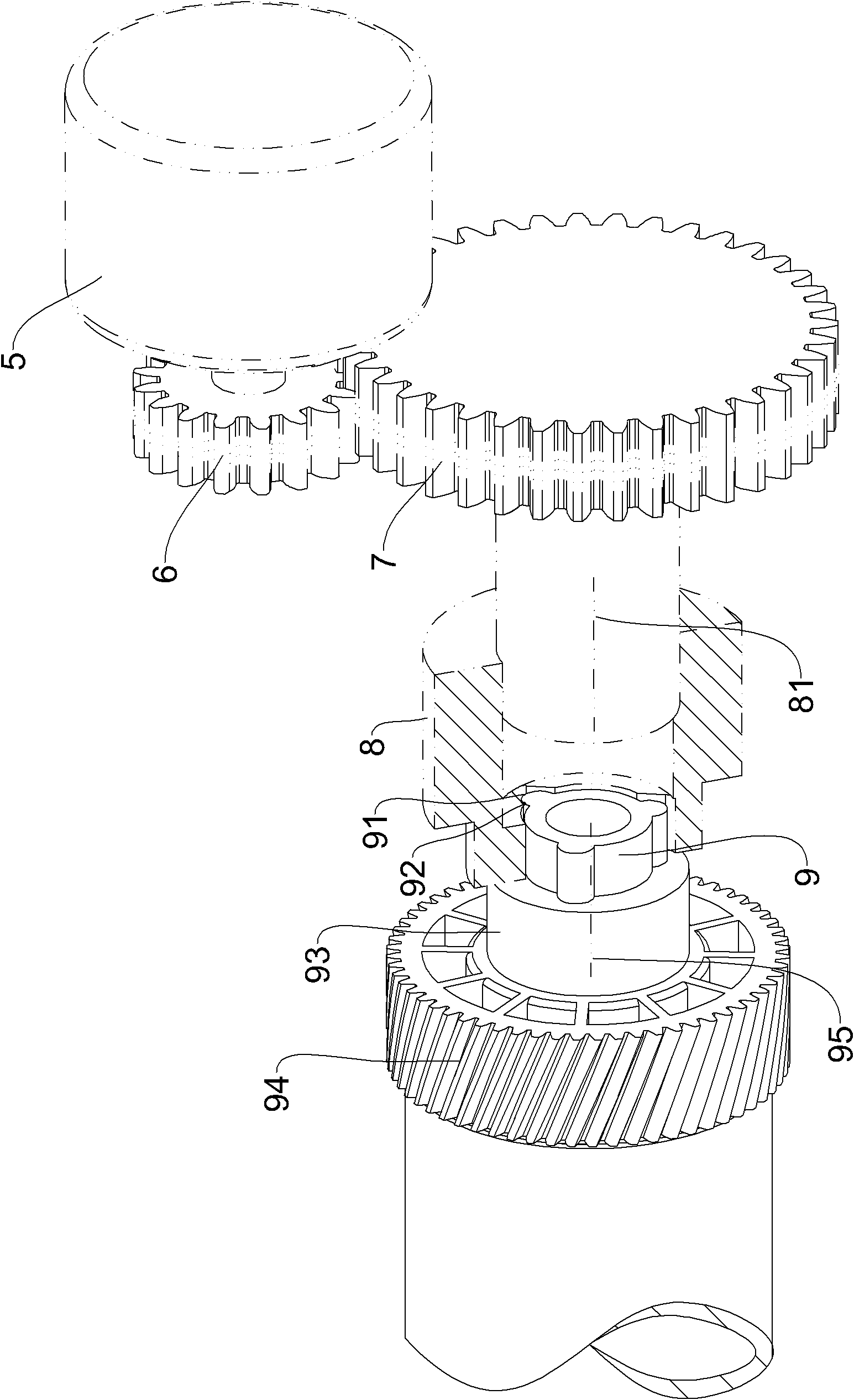

[0030] see Figure 4 , the ph...

Embodiment approach 2

[0037] see Figure 11 and Figure 12 The structure of the photosensitive drum driving assembly 16 of this embodiment is similar to that of the photosensitive drum driving assembly 12 of the first embodiment. It is also composed of a gear 161 and an axial adjustment assembly 162 arranged on the gear 161. The gear 161 can be tightened. Fitted at one end of the drum body 10 , the axial adjustment component 162 can reciprocate relative to the gear 161 along the axial direction of the gear 161 . The axial adjustment assembly 162 includes a driving force receiving head 163 , a driving rod 164 and a toggle pin 165 that can cooperate with the driving force output head 8 .

[0038] The difference is that the driving force receiving head 163 in the photosensitive drum driving assembly 16 of this embodiment is a twisted cylindrical protrusion fixed on the front end of the driving rod 164 .

[0039] see Figure 13 to Figure 16 , when the process cartridge is installed on the image form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com