Ship block assembly quick alignment device and method

An alignment device and segmented assembly technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor alignment accuracy, long construction period, low utilization rate of cranes, etc., to improve quality and efficiency, The effect of improving construction accuracy and shortening construction cycle

Inactive Publication Date: 2011-06-15

DALIAN UNIV OF TECH

View PDF5 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the segmental closing method mainly follows the two traditional methods of assembly workers and crane drivers cooperating with each other for hoisting, positioning and installation, and using a slipway trolley to close up. There are low utilization rate of the crane, complicated operation, poor alignment accuracy, long time, and danger. advanced questions

The segmental assembly, segmental final assembly, and berth assembly and positioning of the hull segment are still in the state of manual operation. A common method is that the assembler and the crane driver cooperate with each other to lift, position and install. The supporting pier below the segment is non-adjustable. For ordinary marine piers, the movement of the section position and the adjustment of the posture all depend on the crane and manpower. During this period, the crane cannot be used for other purposes, and the accuracy is not easy to control during the hoisting and positioning process using the crane. There are large gaps in the section welds. The stress affects the construction quality, and there are problems such as low crane utilization rate, poor alignment accuracy, long construction period, and high risk

At present, there are also vertically adjustable piers in shipyards. This pier has a jacking cylinder, which can adjust the sections in the height direction, but cannot realize horizontal and left-right adjustments. In order to shelve the sections, they must be frequently transported and stacked heavily. pier wood

The number of these manual operations is large, the weight is heavy, and the distance between the bottom of the ship and the surface of the berth is only 1.2m-1.8m. The operation is often carried out under the condition that people cannot stand upright, with low work efficiency, many working hours and heavy labor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

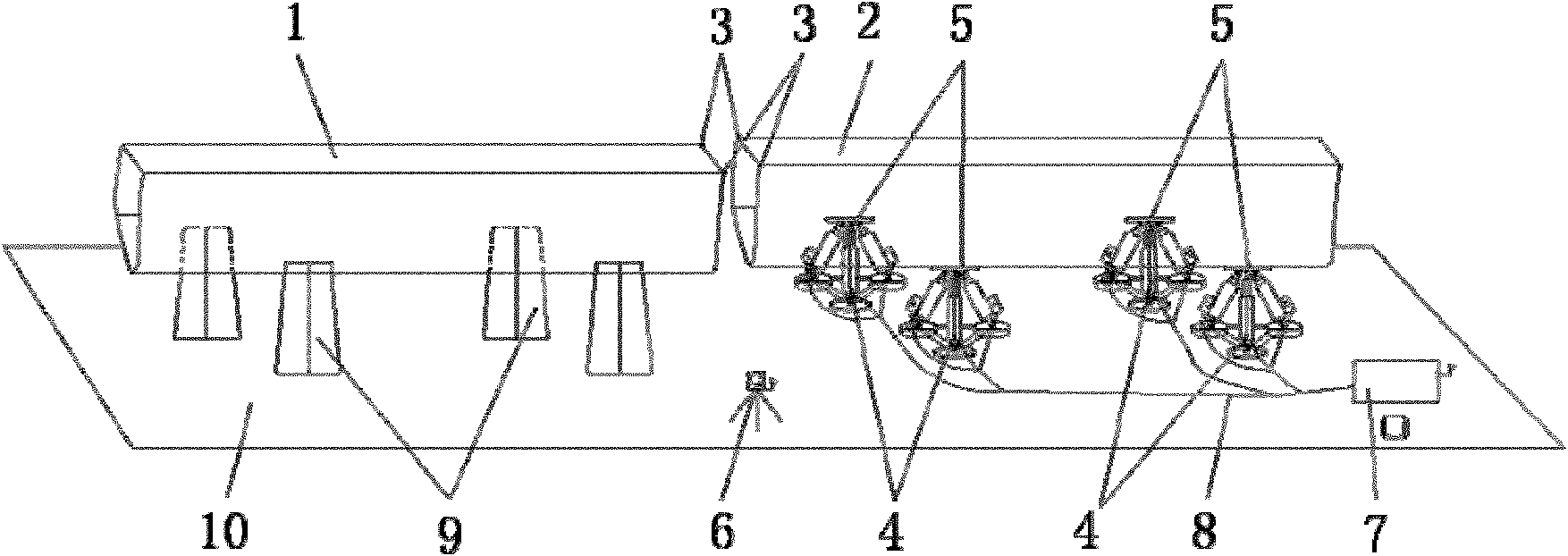

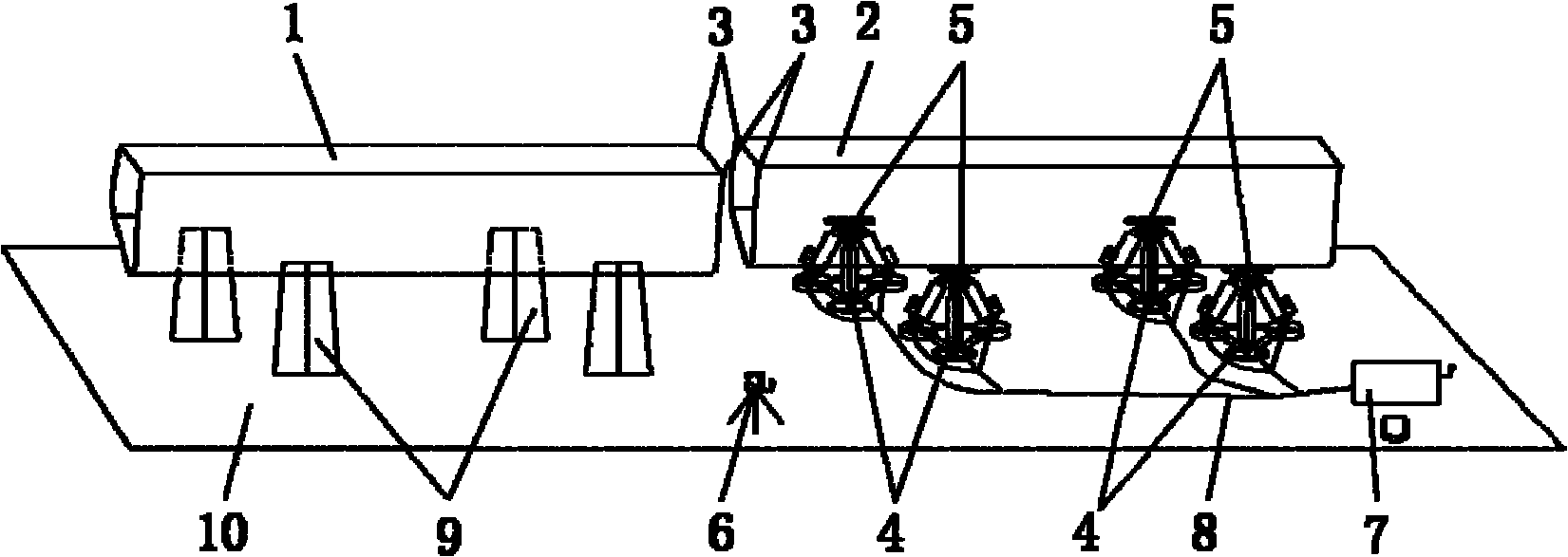

The invention discloses a ship block assembly quick alignment device and a ship block assembly quick alignment method, can be used for adjusting ship block positions and postures in states such as shipway block assembly, general block assembly, shipway assembly and the like, and belongs to the technical field of ship block assembly devices. Aiming at the characteristics of large scale, large tonnage, complicated appearance, low possibility of being moved and accurately aligned and the like of the shipway block assembly, the ship block assembly quick alignment device is designed and developed, and can realize six degree-of-freedom axial shifting and rotating motion of the ship blocks on a universal adjustable platform. The automatic alignment system with accurate alignment function can quickly free cranes, save manpower, improve the quality and efficiency of block folding, and facilitate improving ship building accuracy and shortening construction period.

Description

technical field [0001] The invention relates to a fast alignment device for segmented hull assembly and a method thereof, which can be used to adjust the segmented position and attitude of the hull in the states of segmental assembly, segmental assembly, and berth assembly, and belongs to the technical field of hull segmental assembly devices . Background technique With the application of slipway assembly technology without margin, the efficiency and quality of slipway assembly have been greatly improved. At present, the segmental closing method mainly follows the two traditional methods of assembly workers and crane drivers cooperating with each other for hoisting, positioning and installation, and using a slipway trolley to close up. There are low utilization rate of the crane, complicated operation, poor alignment accuracy, long time, and danger. advanced questions. The segmental assembly, segmental final assembly, and berth assembly and positioning of the hull segme...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23P19/10

Inventor 王运龙林焰秦品乐陈明纪卓尚金朝光于雁云陆丛红李树立

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com