Automatic bevel edge bonding machine

An edge banding machine and bevel edge technology, applied in the field of bevel edge automatic edge banding machines, can solve the problems affecting edge banding quality and work efficiency, and achieve the effect of high edge banding efficiency and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

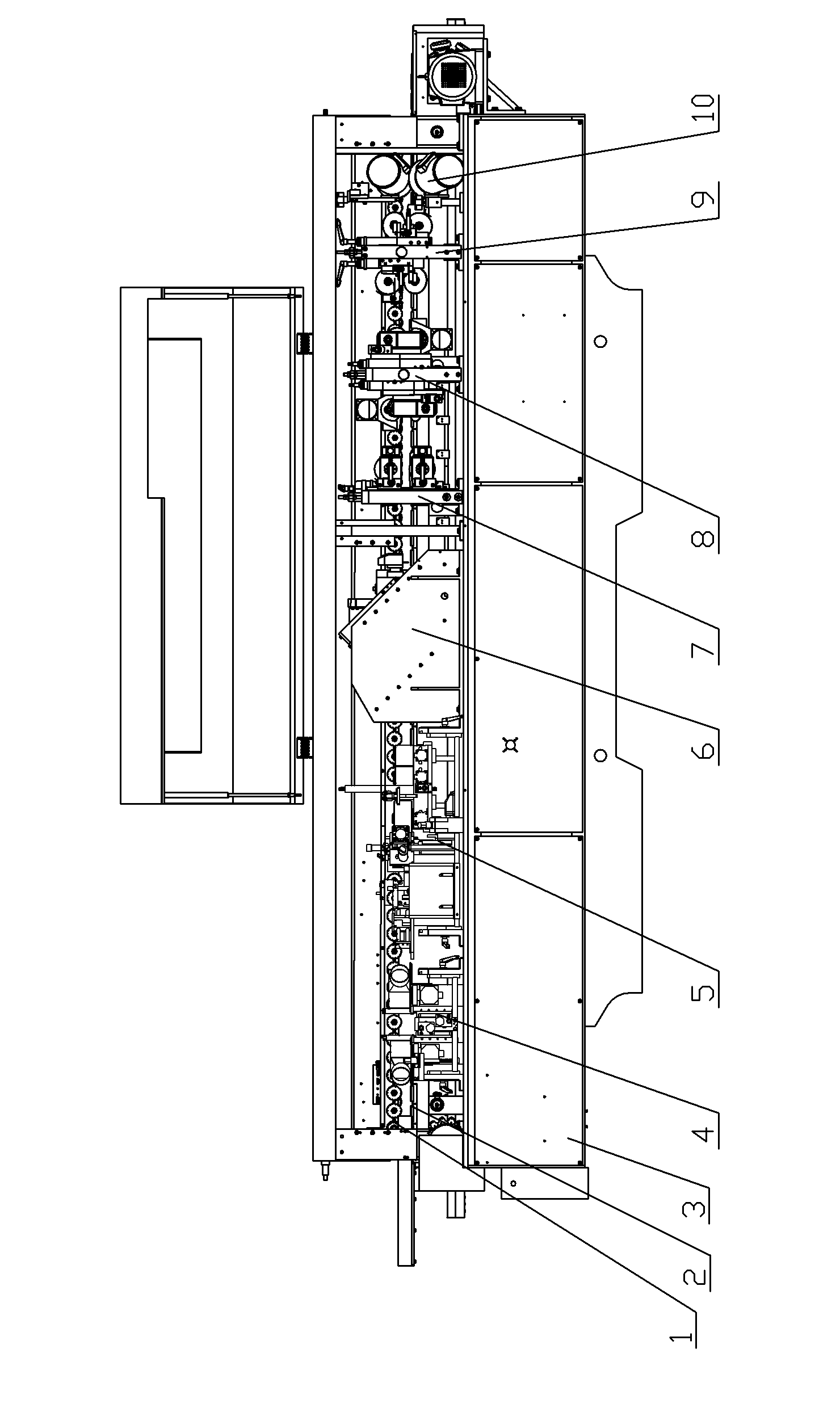

[0027] see image 3 , which is a schematic diagram of the whole machine of the beveled edge automatic edge banding machine of the present invention. The beveled edge automatic edge banding machine of the present invention includes a roller pressing device 1, a chain feeding device 2, a frame 3, a beveled edge belt feeding, gluing, belt cutting, belt pressing device 5, a front and rear rough repair device 6, an up and down coarse Repairing device 7, upper and lower finishing device 8, upper and lower edge scraping device 9 and upper and lower polishing device 10, roller pressing device 1 and chain feeding device 2 are installed on the frame 3 facing up and down, and the beveled side is fed, glued, Belt cutting and pressing device 5, front and rear rough repair device 6, upper and lower rough repair device 7, upper and lower finishing device 8, upper and lower edge scraping device 9 and upper and lower polishing device 10 are sequentially installed on the same side of the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com