Dual-track self-traveling trolley mechanism

A technology of self-propelled trolley and traveling mechanism, which is applied to conveyors, motor vehicles, mechanical conveyors, etc., can solve the problems of unstable operation, large jitter, and high requirements on workpiece positioning accuracy, and achieve the effect of maintaining stability and reducing jitter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

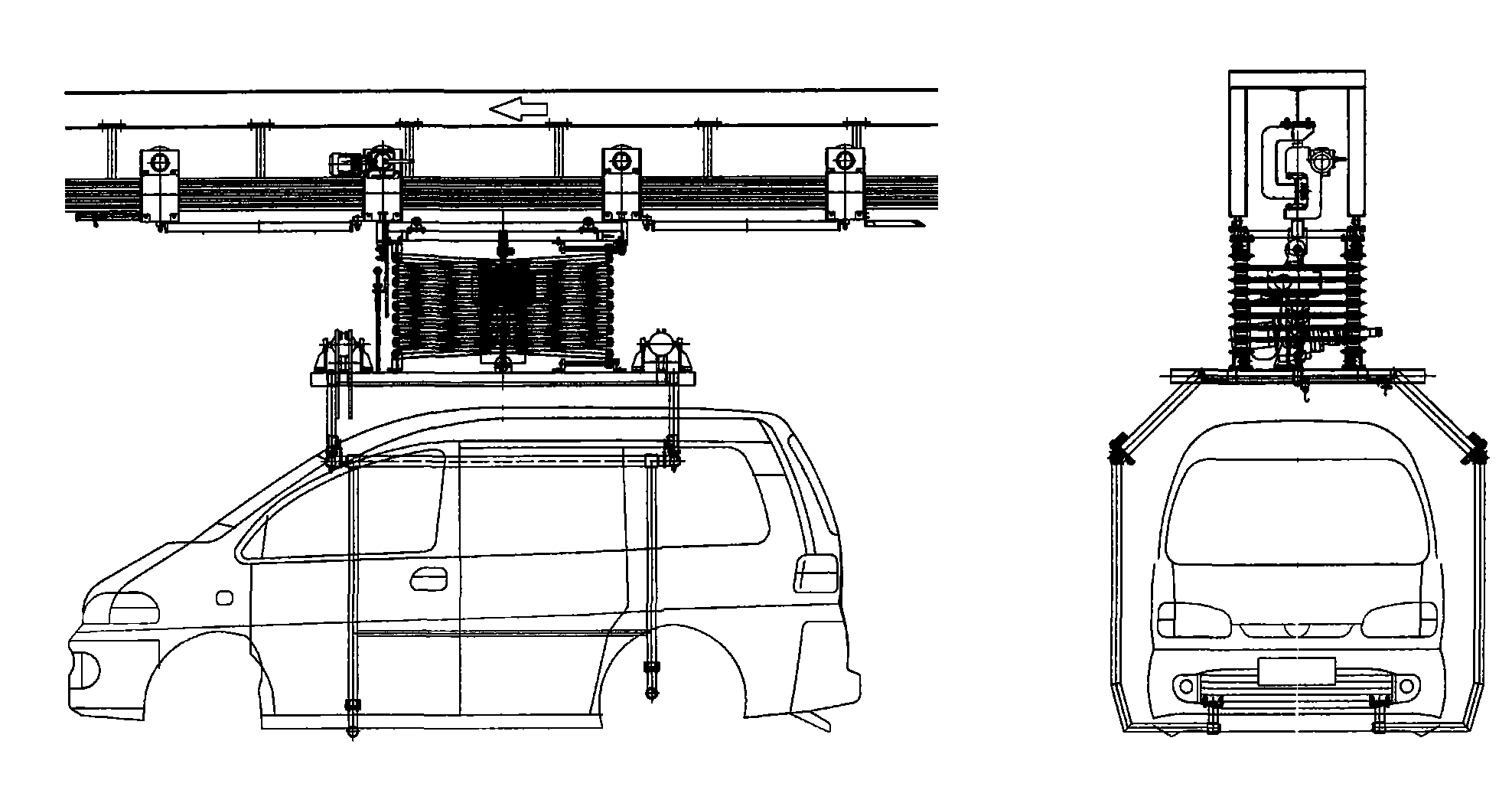

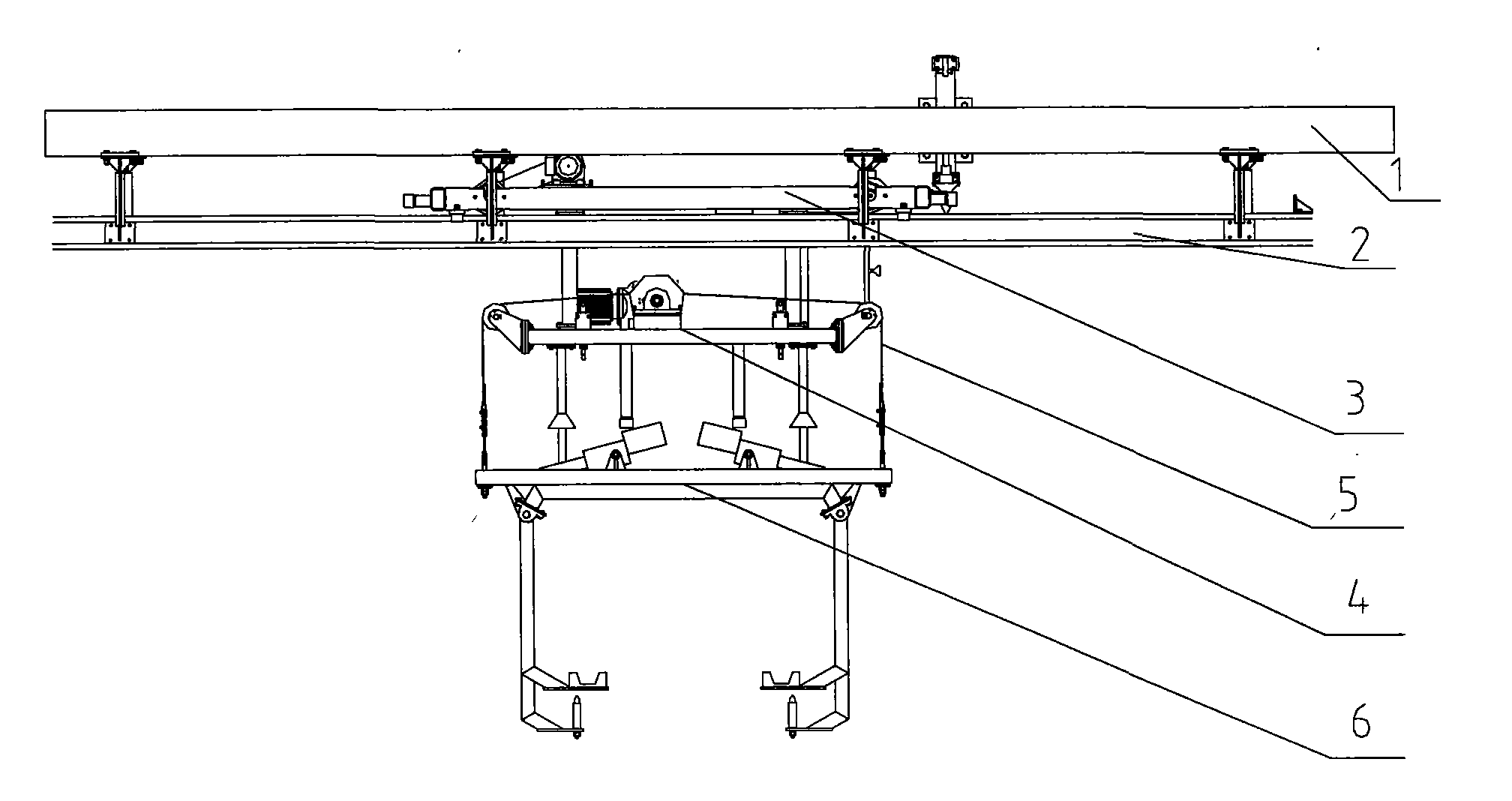

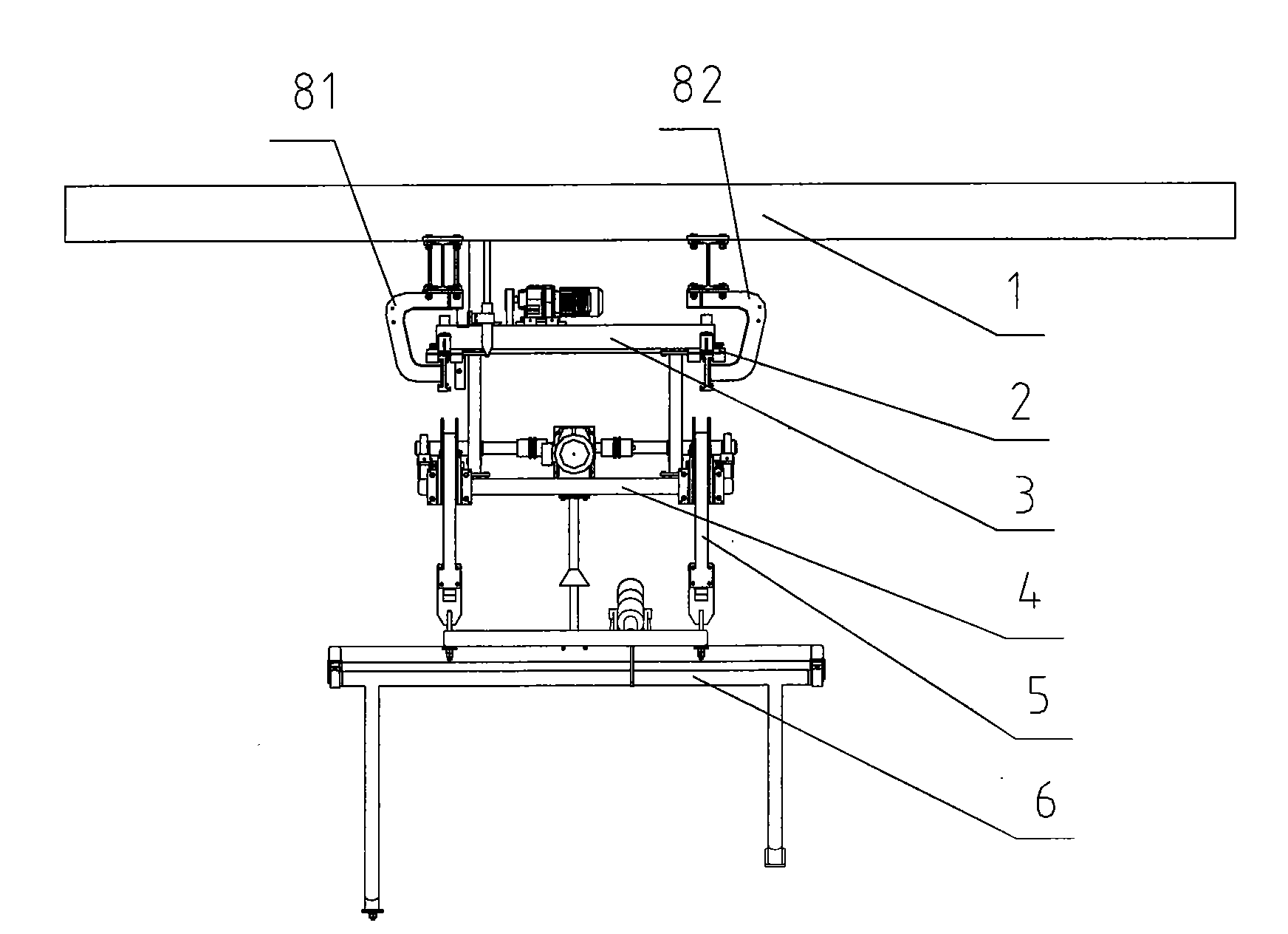

[0027] Such as figure 2 , 3 , 4, the double-track self-propelled trolley mechanism of the present invention comprises the I-beam 1 that is used to fix double-track, double-track 2, the running mechanism 3 that runs on the double-track 2 by traveling wheel, the elevating mechanism 4 that is fixed under the running mechanism 3 and passes activity The sling 5 is connected to the hanger 6 under the lifting mechanism 4, and the traveling mechanism 2 is equipped with a positioning guide sleeve 21, and the positioning guide sleeve 21 cooperates with the positioning guide device 11 fixed on the I-beam 1 for positioning, so The lifting mechanism 4 is a frame type arranged horizontally, and the movable sling 5 has two groups and is arranged in parallel on the mounting support of the frame of the lifting mechanism 4 .

[0028] The working process of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com