Lower supported hanging basket in bridge construction and application thereof

A technology for bridge construction and beams, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of slow movement of the upper-loaded hanging basket, complex setting of anti-tensioning supports, and low reuse rate of slideways, etc., to achieve The shape of the hanging basket is stable, the effect of saving pre-embedded steel materials and preset procedures, and shortening the walking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

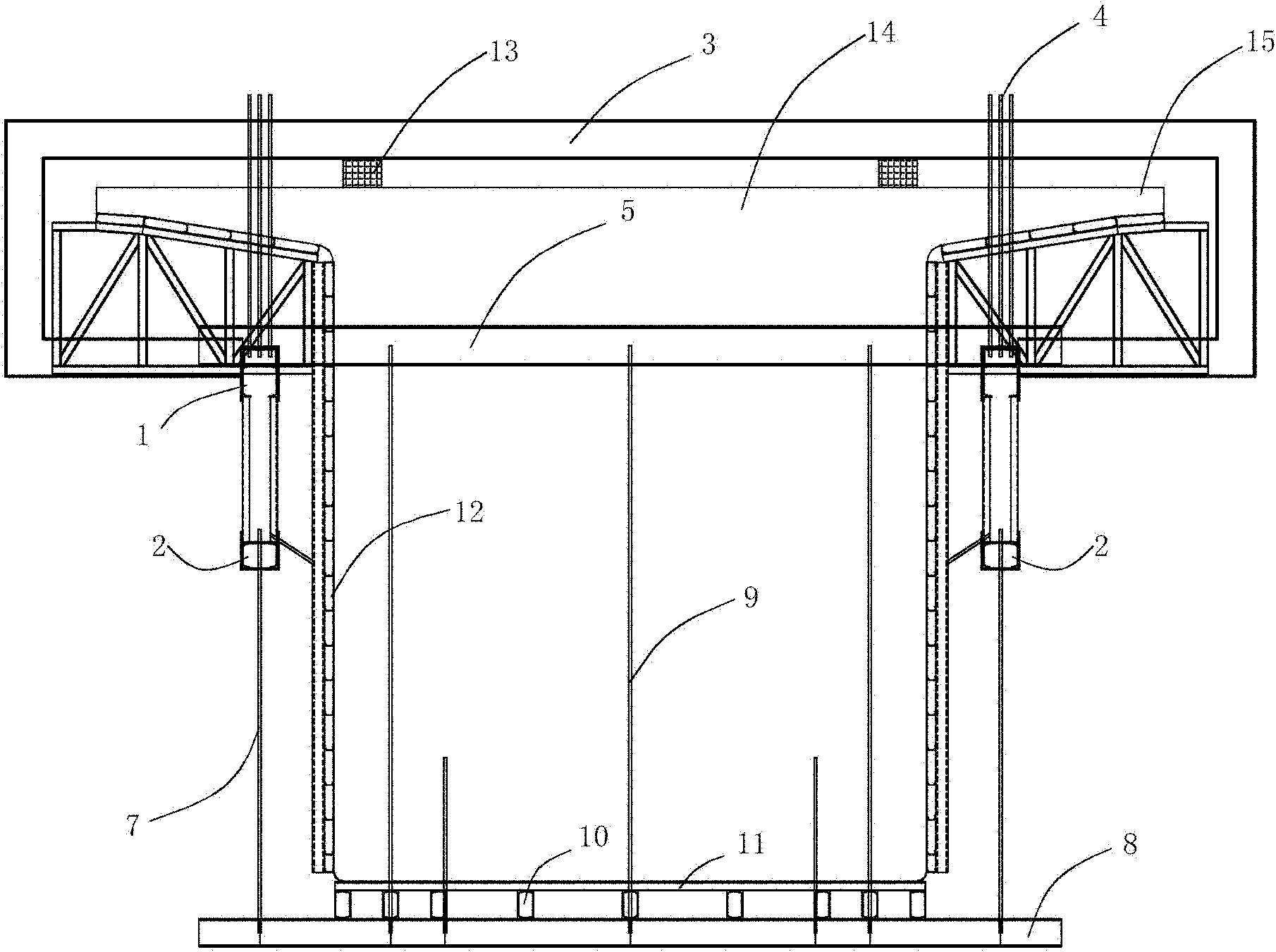

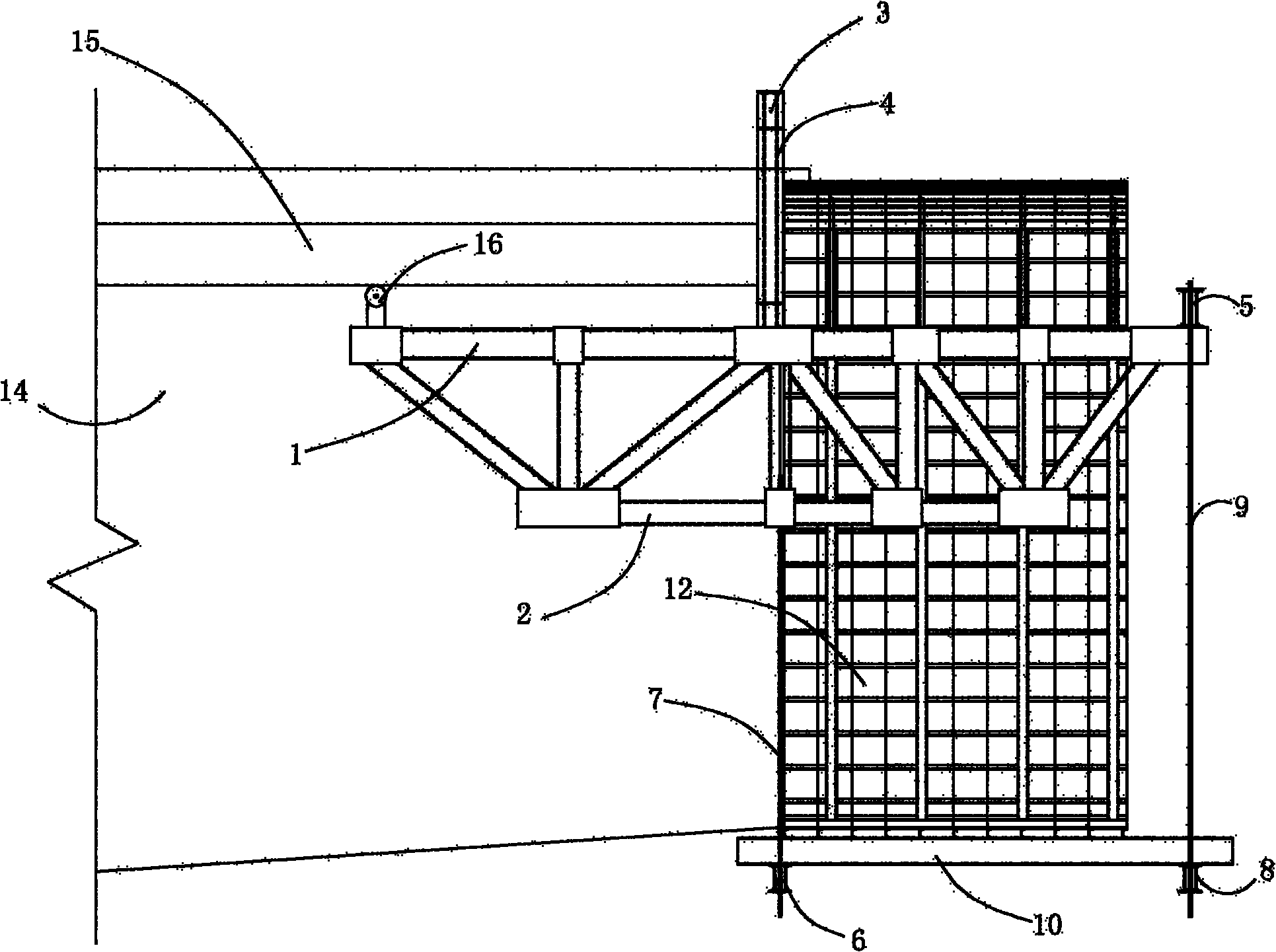

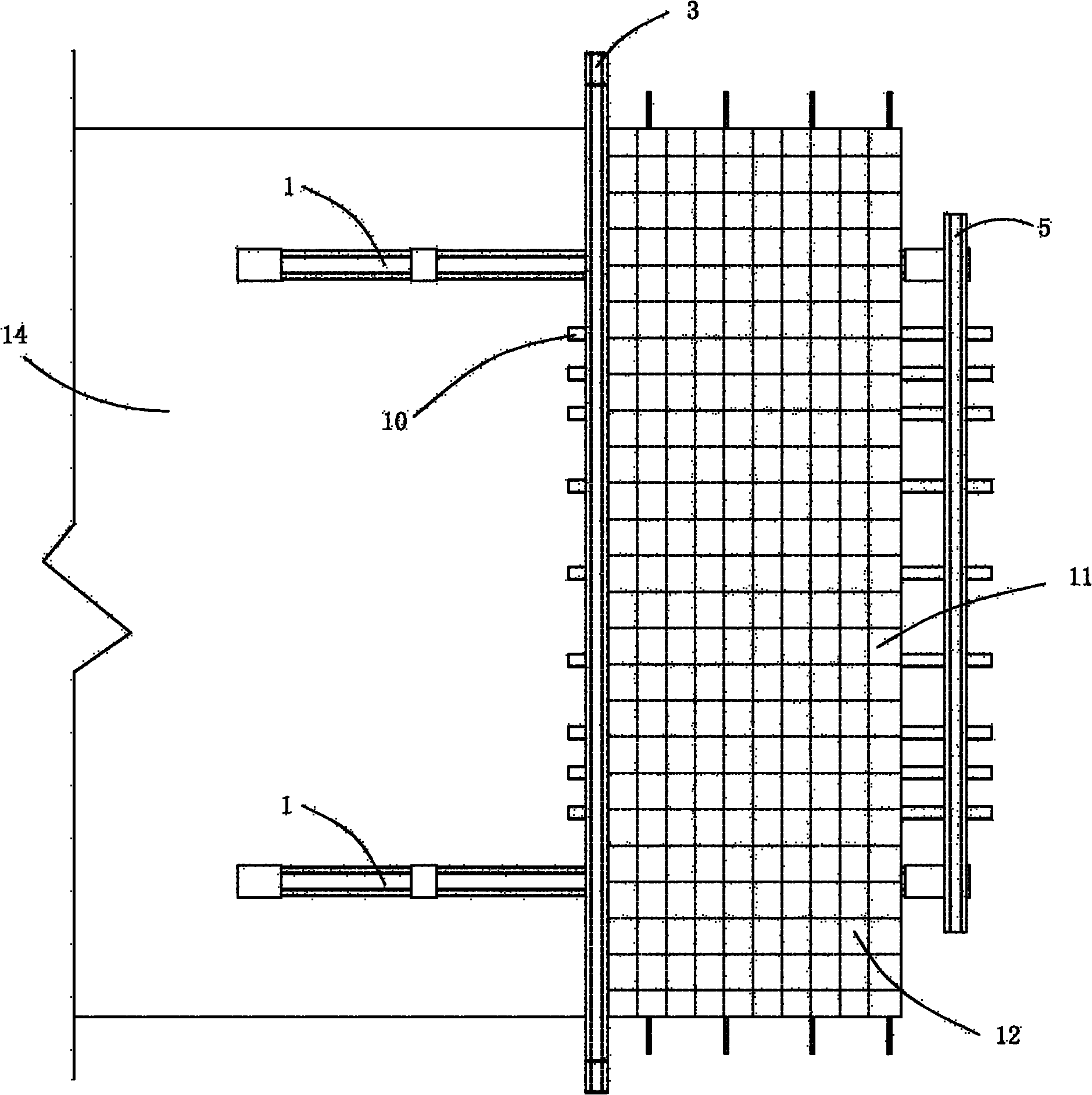

[0031] see figure 1 , figure 2 and image 3 , the structural form of the lower bearing hanging basket in the present embodiment is:

[0032] The under-supporting hanging basket in the bridge construction in this embodiment has two pieces of inverted trapezoidal main trusses, which are composed of upper chord 1, lower chord 2, vertical and oblique rods connected between upper chord 1 and lower chord 2 ; Between the afterbody of the upper chord 1 and the bottom surface of the poured beam section box girder flange 15, the upper chord jacking jack is set, and a pair of walking wheels 16 with the bottom surface of the box girder flange as the supporting surface are set; The rear upper boom 4 is set between the middle part and the rear upper beam 3; the front end of the upper chord 1 is connected with the front upper beam 5; the rear lower boom 7 is set between the middle part of the lower chord 2 and the rear lower beam 6; 5 is connected with the front suspension rod 9 between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com