Ultrahigh pressure flat plate gate valve

A flat gate valve, ultra-high pressure technology, used in sliding valves, valve details, valve devices, etc., to achieve the effect of short structural length, good valve rigidity, and low erosion and erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

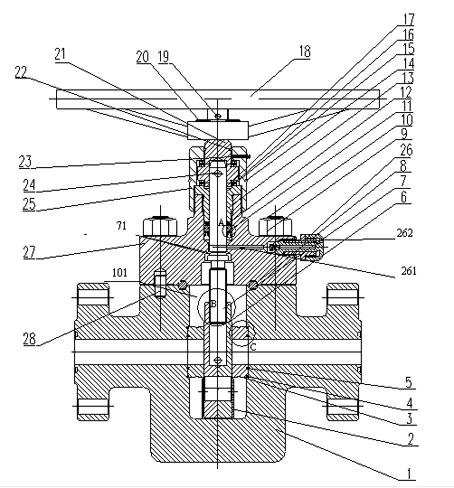

[0049] According to the following Figure 1 to Figure 5 , the preferred embodiment of the present invention is described in detail.

[0050] like figure 1 Shown is a sectional view of an ultra-high pressure flat gate valve provided by the present invention, and the ultra-high pressure flat gate valve includes:

[0051] valve body 1;

[0052] The guide plate 2 is arranged in the inner cavity of the valve body 1, and the groove of the guide plate 2 is consistent with the direction of the through hole of the valve body 1;

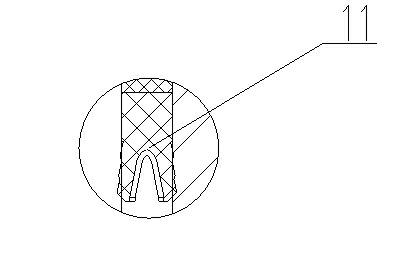

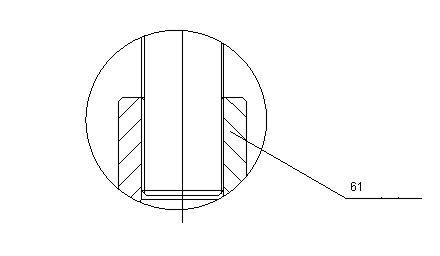

[0053] The valve seat 3 is arranged in the inner cavity of the valve body 1. The two valve seats 3 are respectively located on both sides above the guide plate 2. The valve seat 3 is provided with a sealing groove, and the inner sealing ring 5 and the outer sealing ring 4 are respectively arranged in the sealing groove. (like Figure 4 shown), the inner sealing ring 5 and the outer sealing ring 4 are spring-type lip seals;

[0054] The valve plate 6 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com