Split type LED lamp

A split-type technology for LED lamps, which is applied to semiconductor devices of light-emitting elements, lighting devices, and cooling/heating devices for lighting devices. Avoid overheating and enhance the effect of heat dissipation

Inactive Publication Date: 2011-06-15

史杰

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the integral structure will significantly shorten the life of the driving device, which in turn will shorten the life of the LED lamp. This has become a difficult technical problem in the LED field.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

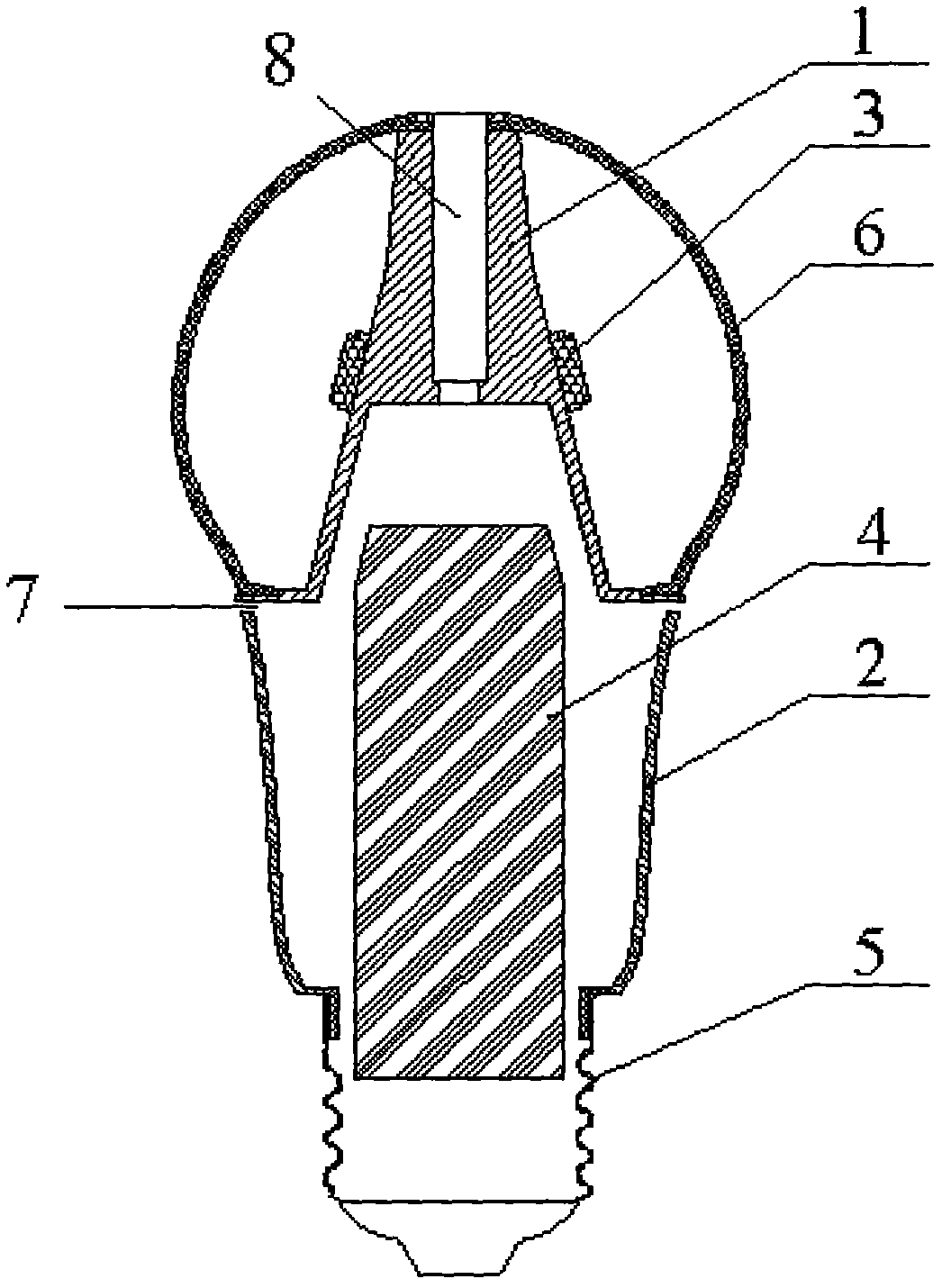

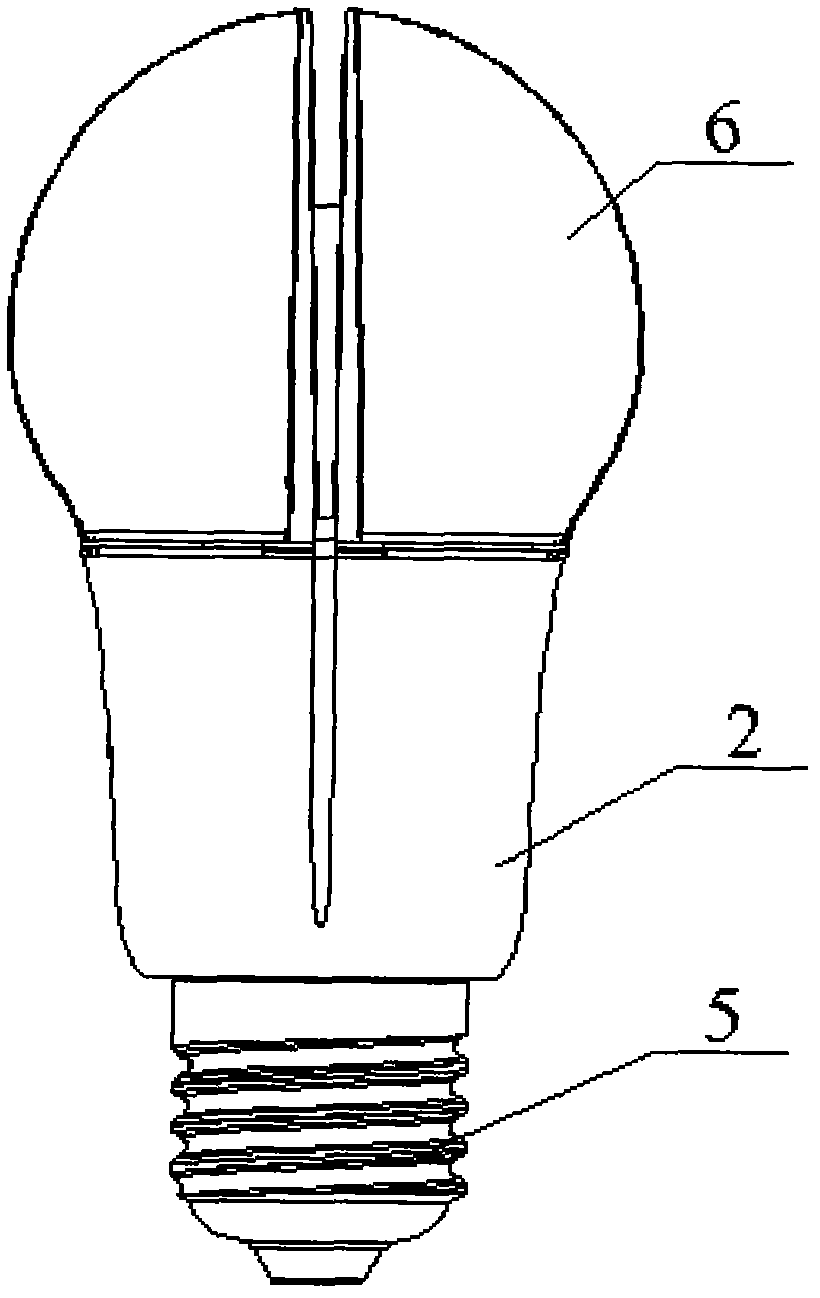

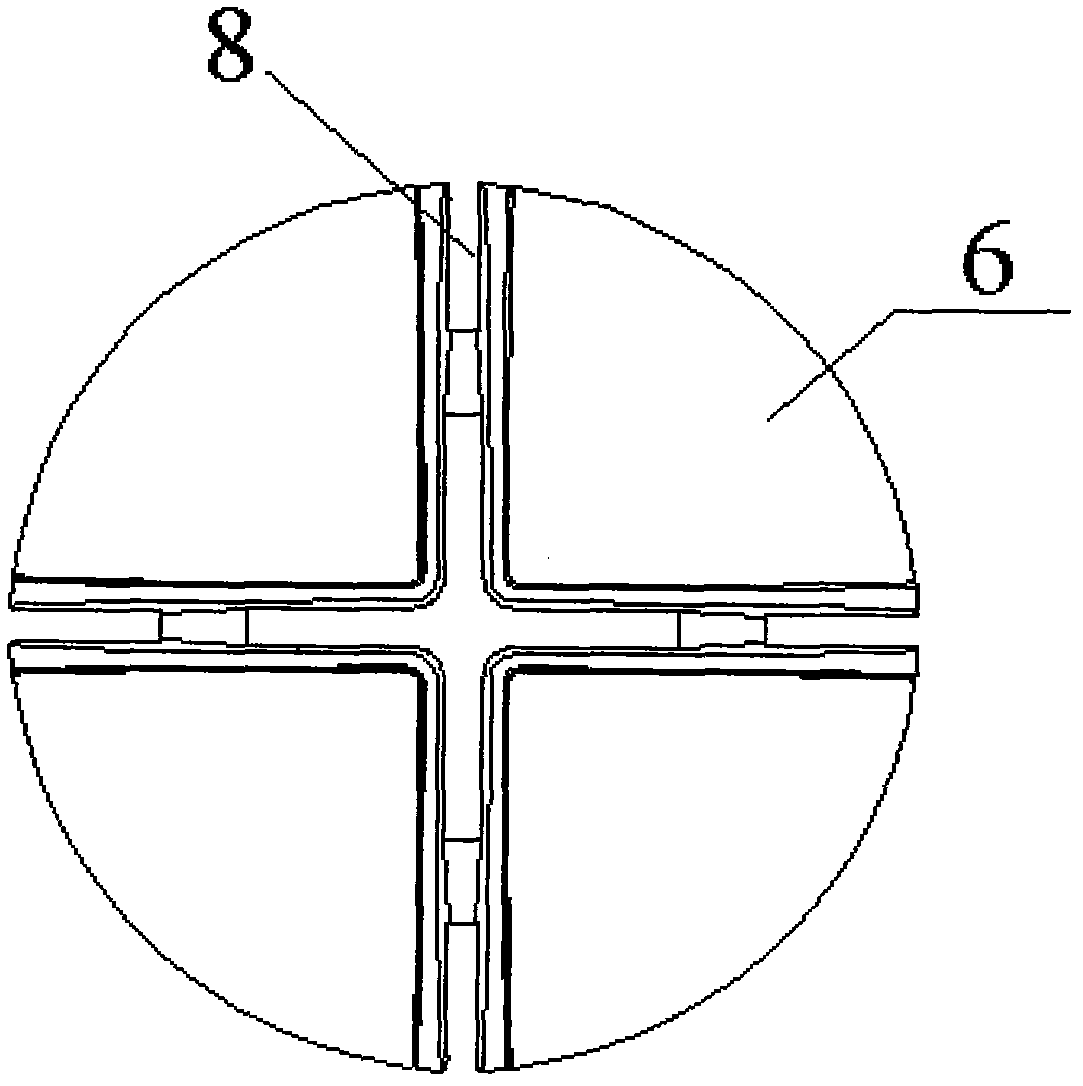

The invention discloses a split type light-emitting diode (LED) lamp, which comprises a radiator (1), an LED light source (3), an LED driving device (4), a lamp cap (5) and an electric box (2) independent from the radiator, wherein the electric box and the radiator are arranged at intervals; the LED light source is fixed on the radiator; and the LED driving device is arranged in the electric box; the lamp cap is fixed on the electric box. The LED lamp is designed into a split type structure to ensure that the radiator is separated from the electric box for placing the driving device, the driving device is prevented from being influenced by the heat of the LED light source; and on the basis of the split type structure, the structure of the radiator of the LED lamp is improved and the heat radiating of the LED lamp is strengthened to well solve the problems of small volume and insufficient space of the LED lamp and improve the performance of the LED lamp.

Description

Split LED lights technical field The invention relates to an LED lamp, in particular to a split-type LED lamp, which belongs to the technical field of LED semiconductor lighting. Background technique LED lights mainly include LED bulbs and LED spotlights. With the improvement of LED performance and the reduction of cost, lighting products using LED as light source have achieved rapid development, and have gradually replaced traditional lighting products in some indoor and outdoor lighting places. Among traditional lighting products, incandescent lamps and tungsten-halogen spotlights are representative types of general lighting sources. Since the luminous efficiency of incandescent lamps and tungsten-halogen spotlights is very low, only about 15lm / W, the use of LED lamps to replace incandescent lamps and tungsten-halogen spotlights has significant energy-saving advantages. However, a problem existing in the LED lamp itself is that the luminous efficacy of the luminaire i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F21S2/00F21V17/00F21V19/00F21V29/00F21Y101/02F21K9/232F21V29/503F21V29/74F21Y115/10

Inventor 史杰

Owner 史杰

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com