Polarizer and manufacturing method thereof

A manufacturing method and polarizing plate technology, applied in chemical instruments and methods, polarizing elements, synthetic resin layered products, etc., can solve the problems of complicated and expensive protective film materials, etc.

Inactive Publication Date: 2011-06-15

BENQ MATERIALS +1

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the present invention provides a polarizing plate and its manufacturing method to solve the problem of expensive and complicated manufacturing process of conventional protective film materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

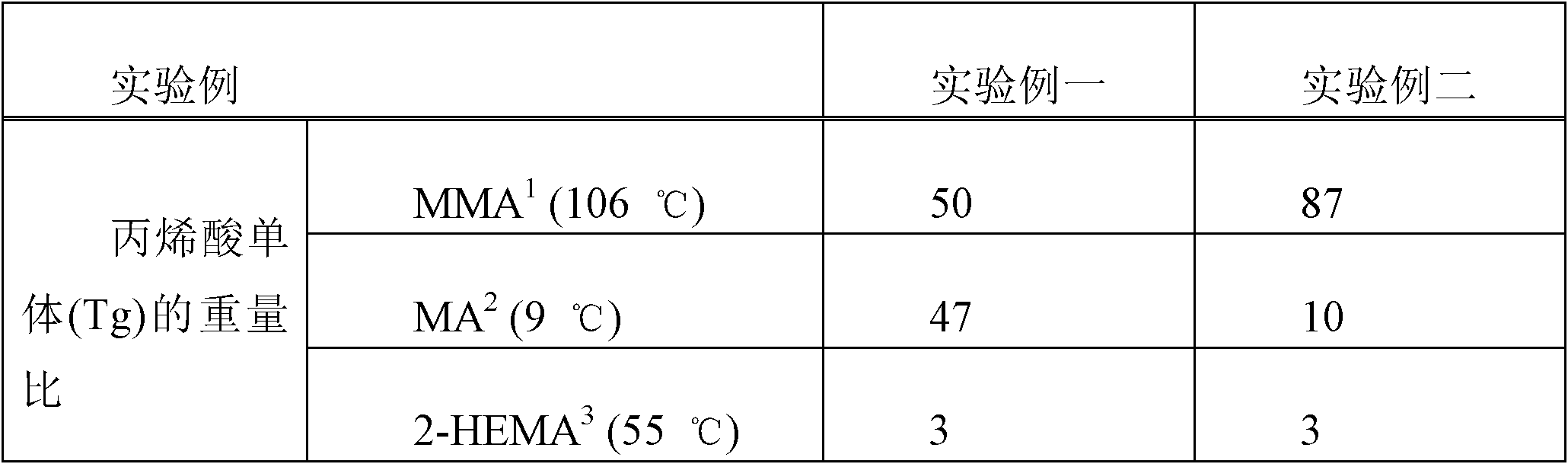

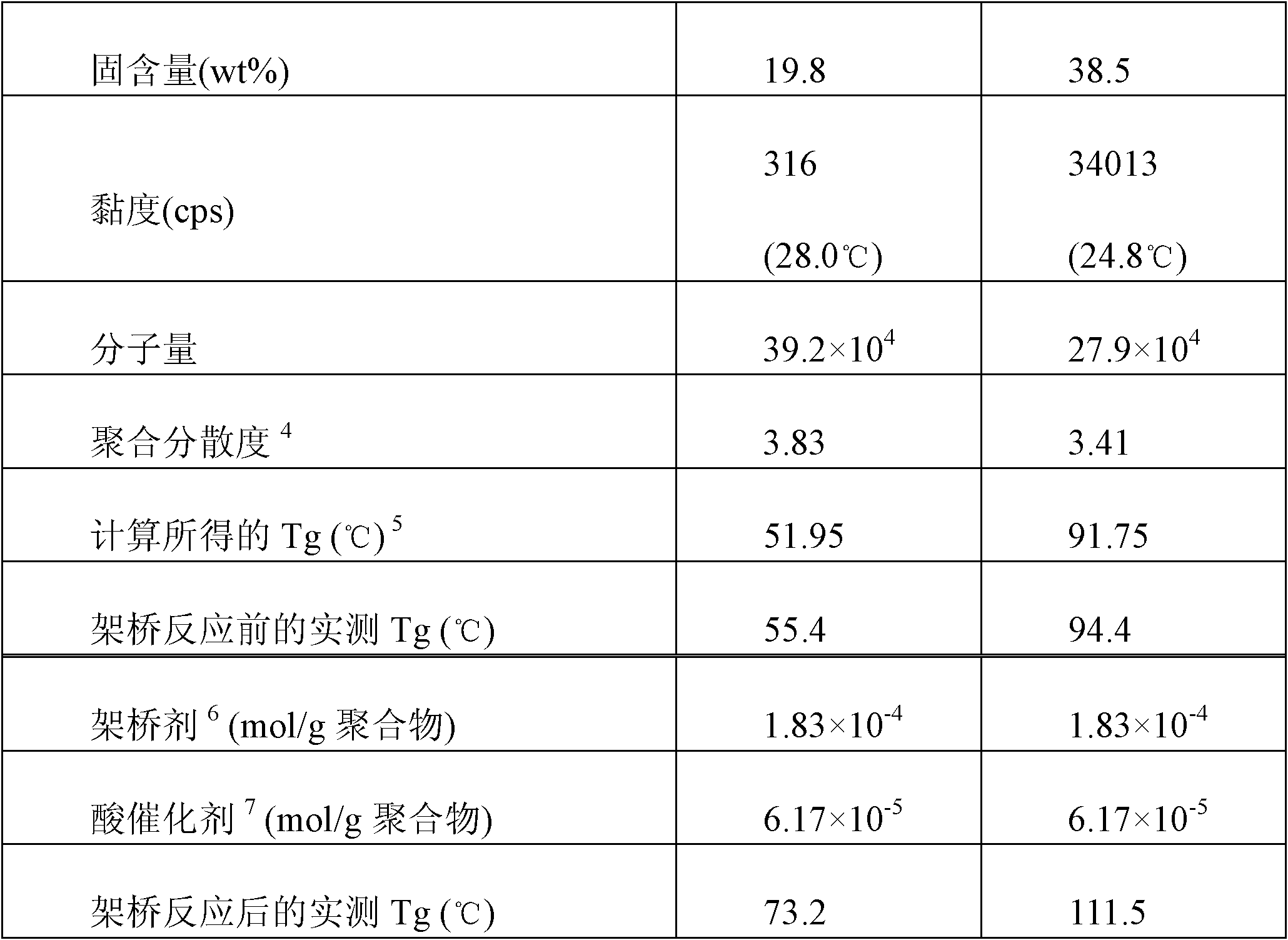

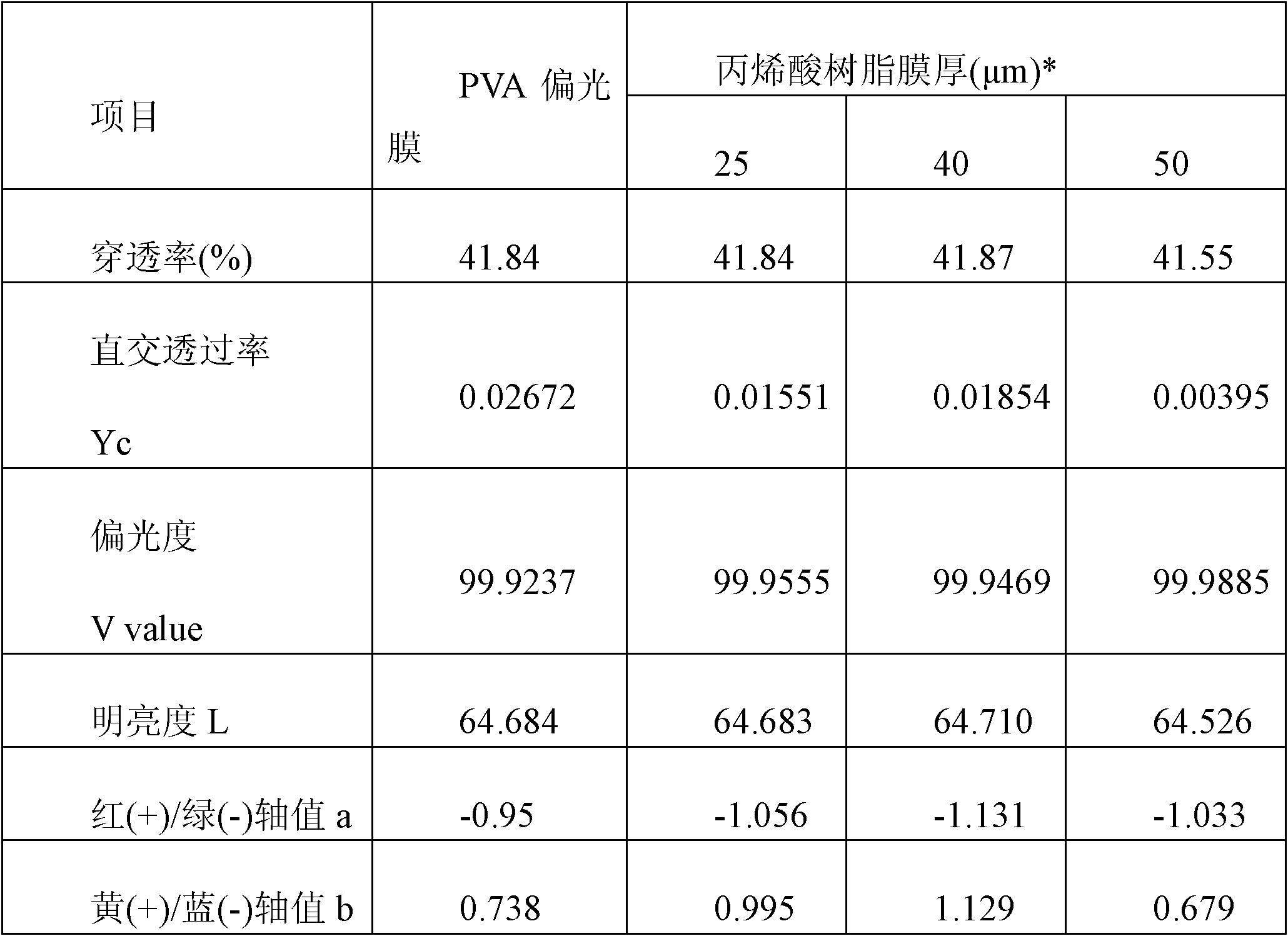

experiment example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a polarizer and a manufacturing method thereof. Acrylic resin serves as a protective film of a polyvinyl alcohol polarizing film to be combined into the polarizer, wherein the acrylic resin has the glass transition temperature of higher than 50 DEG C. Because cheap acrylic resin is used for replacing the conventional expensive protective film material, namely cellulose triacetate and / or cycloolefine polymer; and by utilizing the hot melt adhesive property of the acrylic resin, the acrylic resin protective film and the polyvinyl alcohol polarizing film can be combined through hot pressing only, and the step of coating hydrogel between the acrylic resin protective film and the polyvinyl alcohol polarizing film can be saved. Therefore, due to the implementation mode, the manufacturing cost of the polarizer can be greatly saved, and the manufacture procedure of the polarizer can be simplified.

Description

Polarizing plate and manufacturing method thereof technical field The present invention relates to an optical element and its manufacturing method, and in particular to a polarizing plate and its manufacturing method. Background technique Outdoor large flat-panel displays are often used to provide passers-by or drivers with a lot of information. Among them, one of the key components of the LCD is the polarizer, which accounts for about 6%-18% of the material cost of the LCD. The material of the polarizing film in the polarizing plate structure is usually stretched polyethylene film (polyvinylalcohol; PVA). Since polyvinyl alcohol is soluble in water and the stretched film is easily affected by heat and moisture and shrinks. , so it is necessary to add a protective film on both sides to form the structure of the polarizer, so that the structure of the polarizer can withstand the outdoor sun and rain. Currently, the common material of the protective film of the polarizer...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B27/08G02B5/30B32B27/30

Inventor 蔡政欣张书怡李崇汉

Owner BENQ MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com