Developing cavity and developing machine base

A developing machine and developing solution technology, which is applied in the processing of photosensitive materials, etc., can solve the problems of long developing solution flushing time, inability to develop silicon wafers, and poor developing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

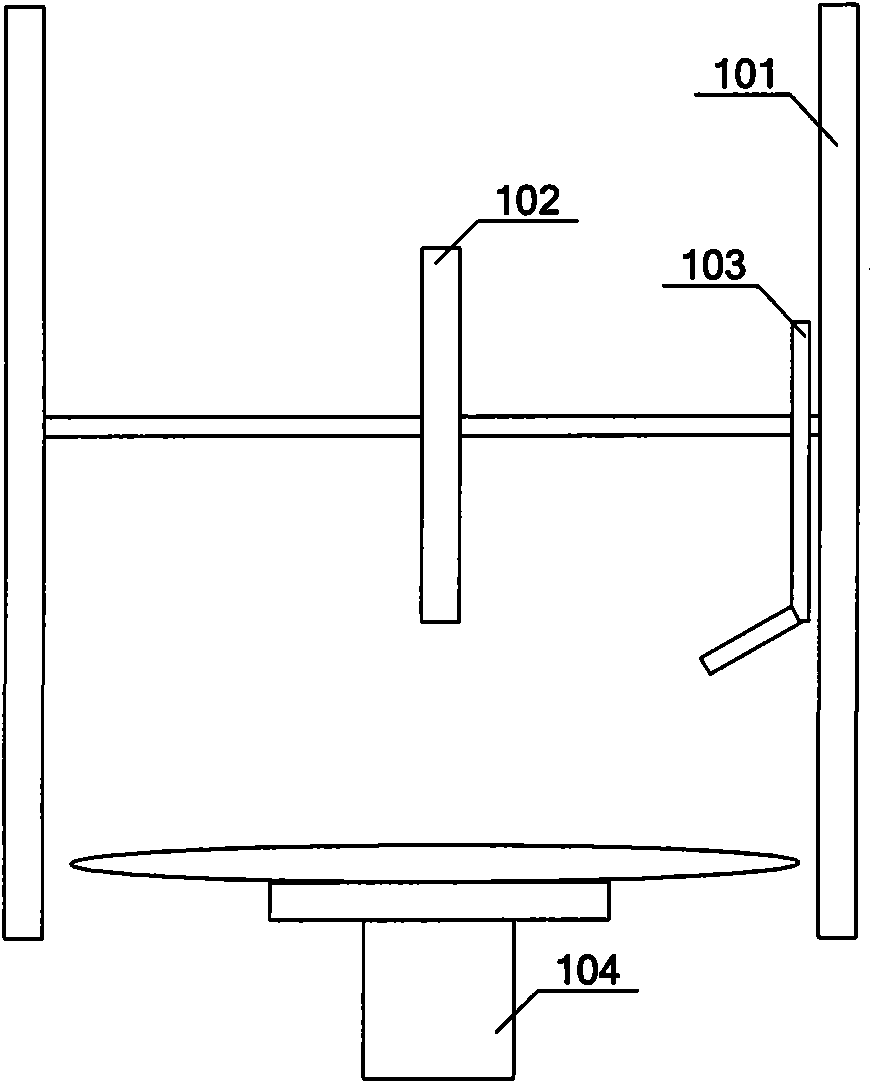

[0023] The embodiment of the present invention provides a developing chamber and a developing machine. On the basis of the developing chamber of the SSI series developing machine, the diameter of the developing solution tube is increased, and the position of the developing solution outlet of the developing solution tube is changed to be vertical. on the loading table, and further make the developer outlet of the developer tube slightly off the center of the loading table, so that the developer flowing out of the developer tube can accumulate on the silicon wafer in a short period of time, thereby optimizing the development Effect.

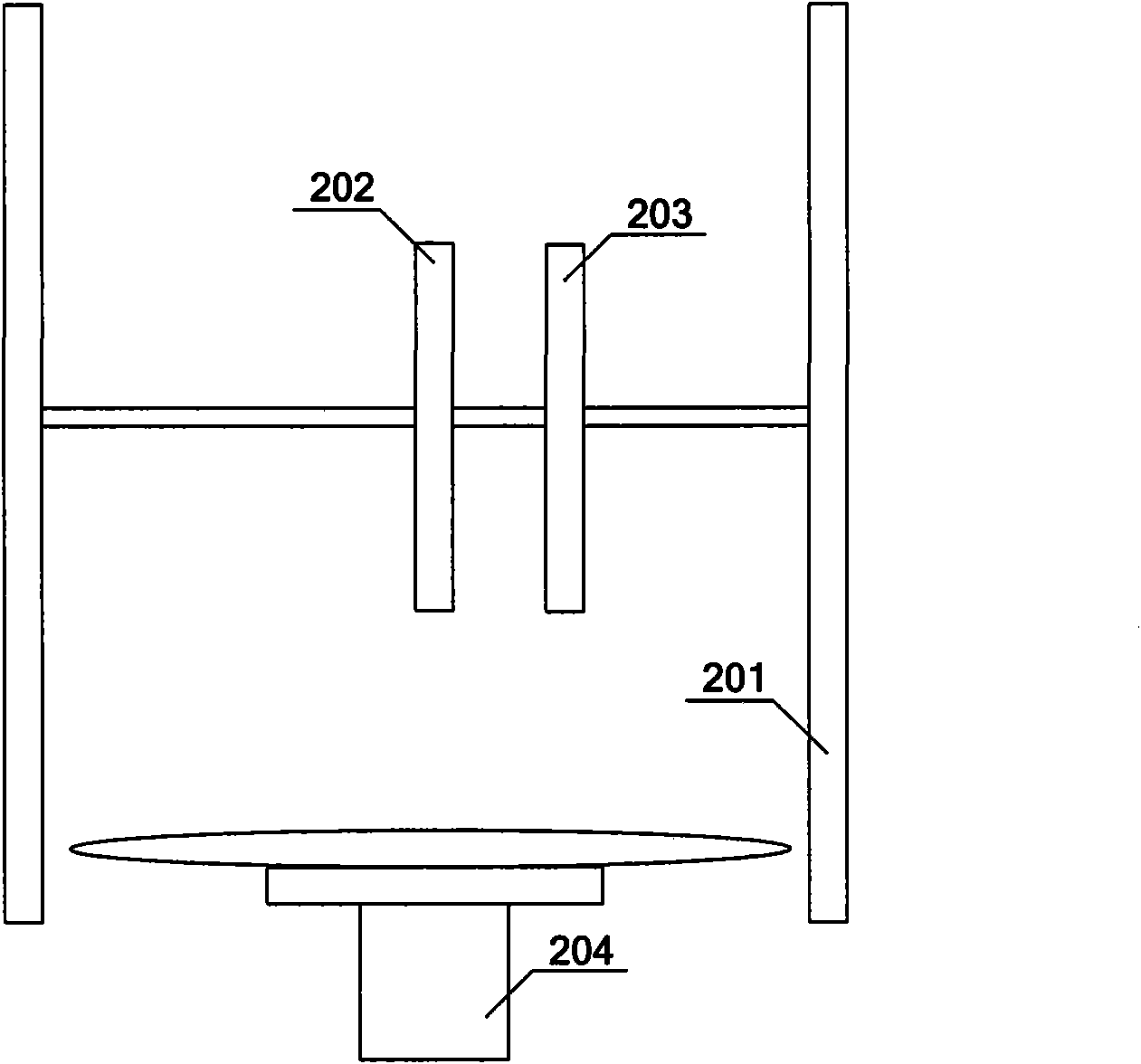

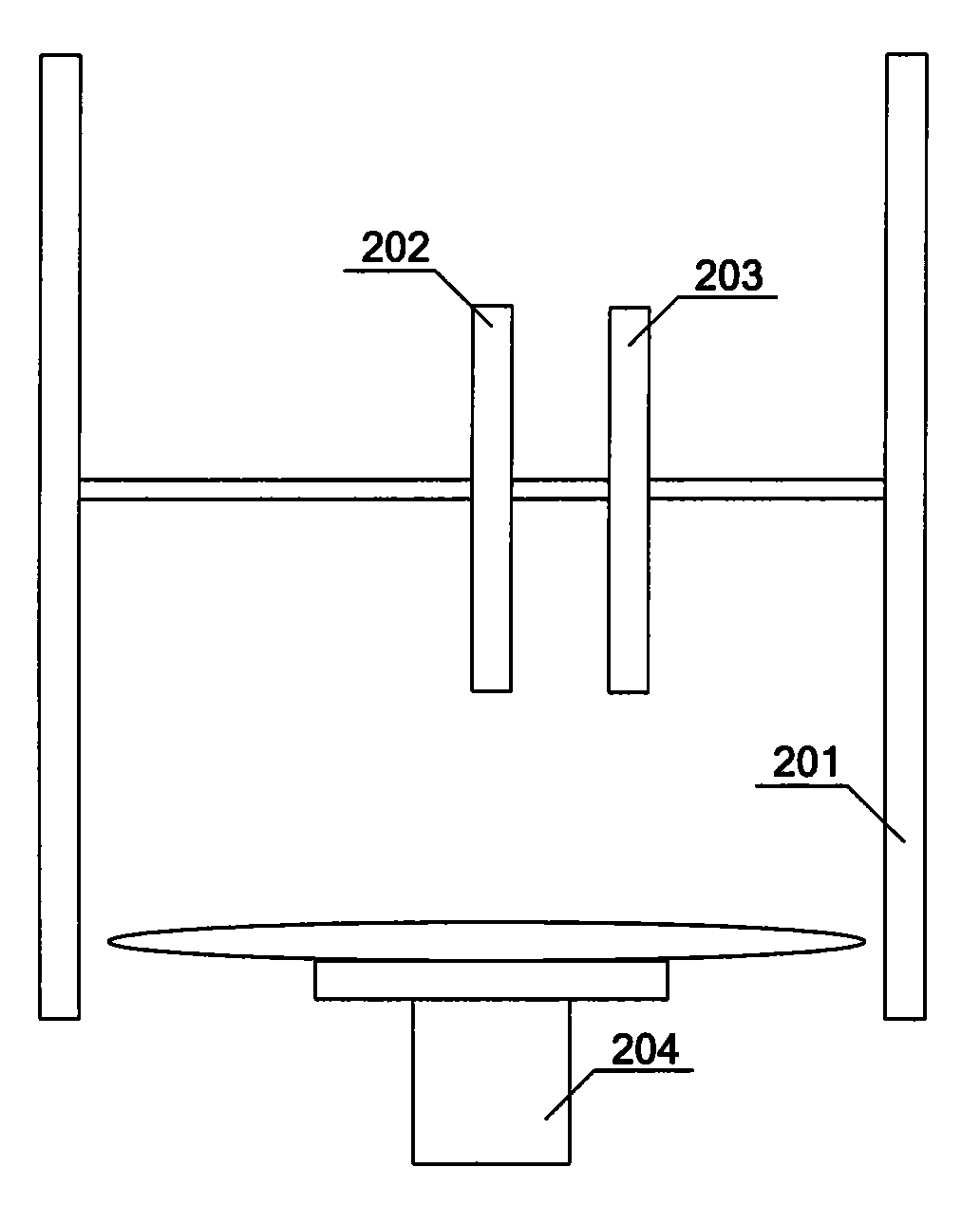

[0024] Such as figure 1 As shown, a developing chamber provided by an embodiment of the present invention includes: a chamber body 201, a flushing water pipe 202, a developing solution pipe 203, and a slide table 204, wherein:

[0025] The flushing water pipe 202, the developer pipe 203 and the slide table 204 are all arranged in the cavity 201, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com