Electrodusting chamber bottom cleaning device and method for cleaning static powder by applying same

A cleaning device, electrostatic powder spraying technology, applied in spraying devices, devices for coating liquid on the surface, coating, etc., can solve the problems of poor powder pumping effect, poor cleaning effect, time-consuming and labor-intensive cleaning, etc., to achieve Low manufacturing cost, good pumping effect and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

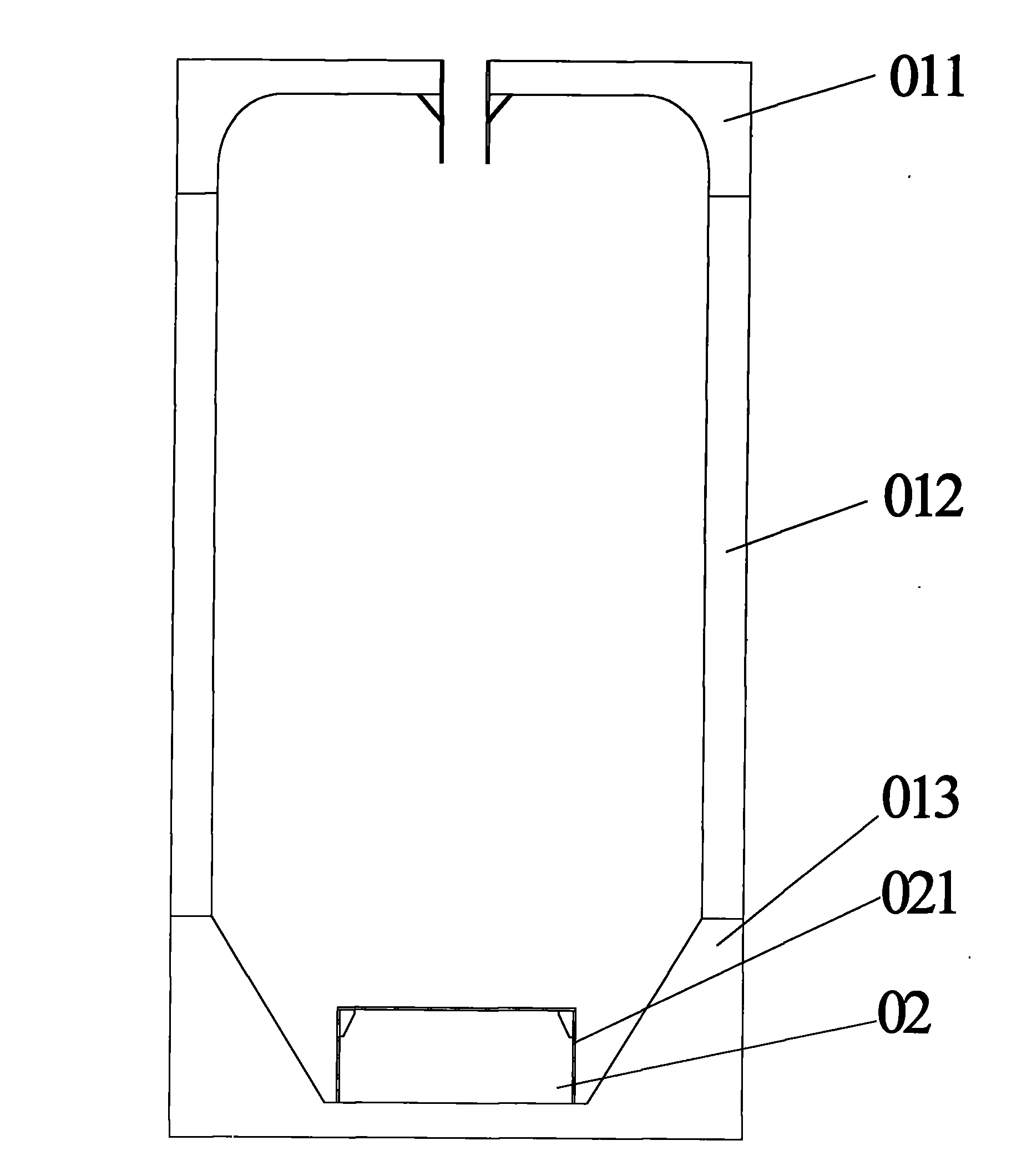

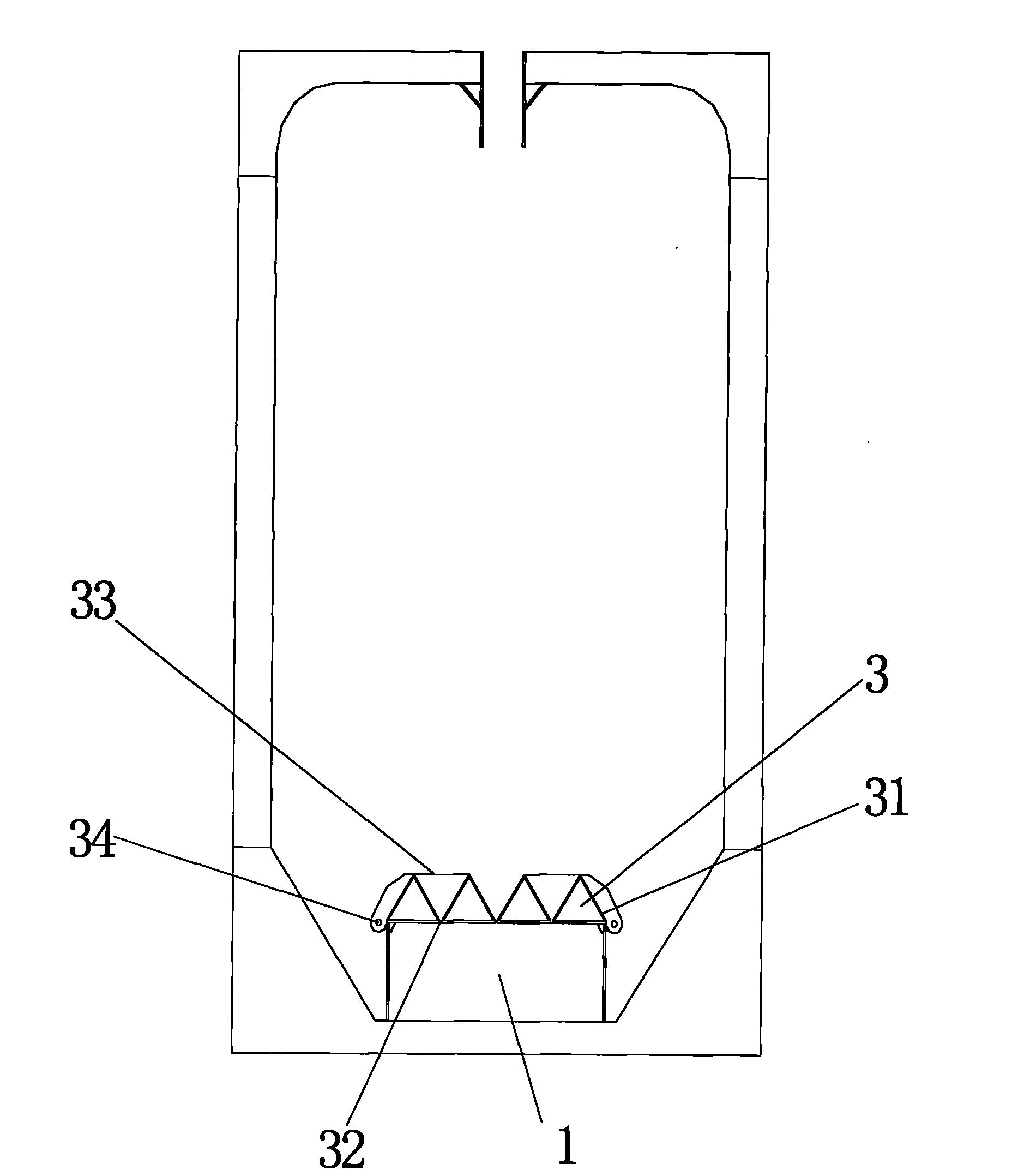

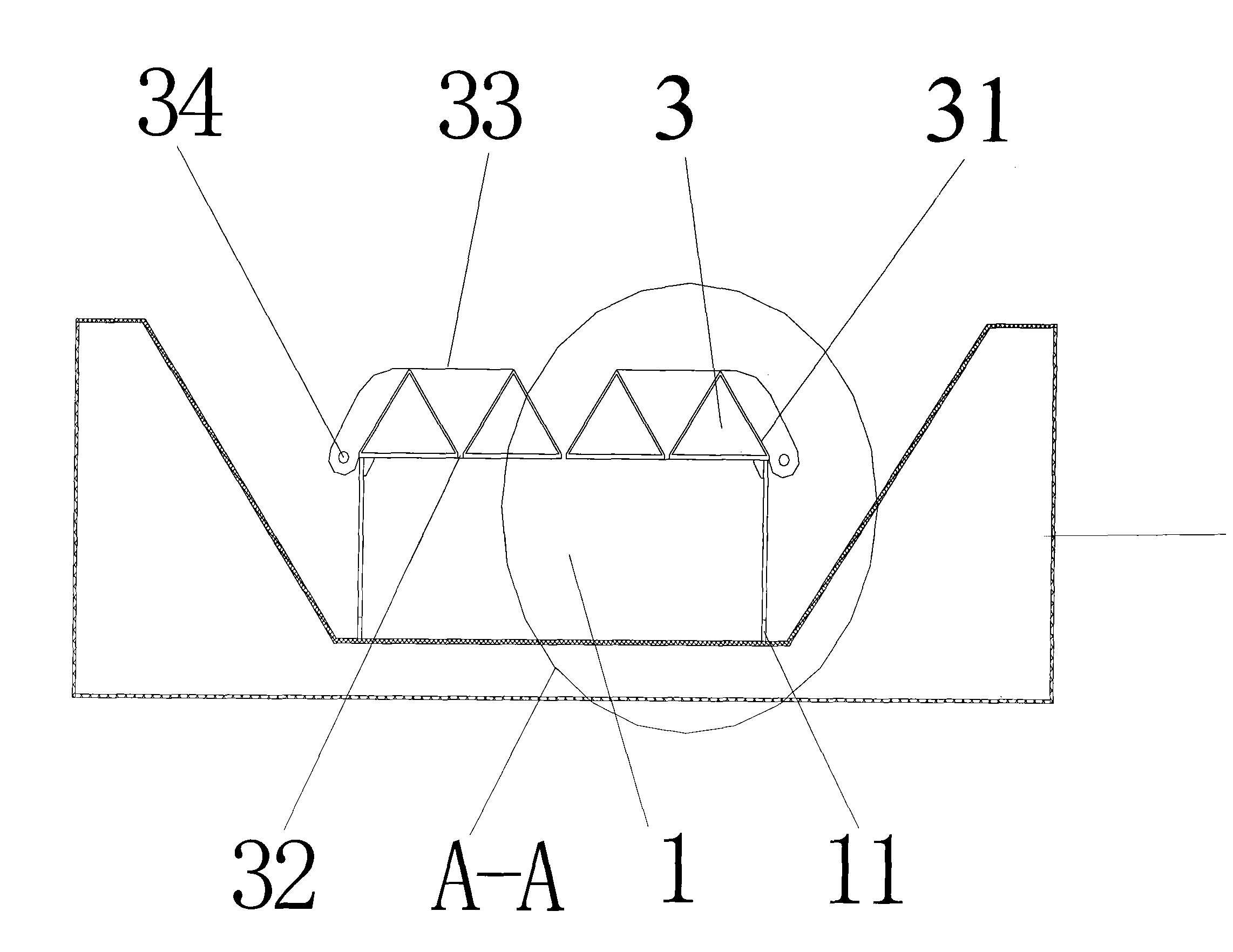

[0020] like figure 2 , image 3 , Figure 4 , Figure 5 As shown, a device for cleaning the bottom of an electrostatic powder spraying chamber includes a negative pressure exhaust pipe 1 located at the bottom of the powder spraying chamber. The top of the exhaust pipe 1 is provided with several powder guiding devices 3. There are ridges or peaks, and inclined guiding slopes 31 are formed on both sides, and gaps 32 for pumping powder are provided between the bottoms of adjacent guiding slopes 31 of adjacent powder guiding devices 3 . The guiding slope 31 is a slope or an arc.

[0021] The cross-sectional shape of the powder guiding device 3 is a hollow triangular sleeve structure, a number of suction ports 11 are provided at the bottom of the side wall of the exhaust pipe 1, and the size of the gap 32 is 5-15 mm. The cross-section of the powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com