Method for preventing mortar spraying machine from being blocked and sieving dust hopper device

A technology of spraying machine and ash bucket, which is applied in the direction of construction and building structure, can solve the problems of cumbersome work of removing coarse aggregate and foreign matter, limiting the scope of application of mortar spraying machines, and the impact on production and construction, so as to broaden the scope of application, Effects of preventing clogging and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

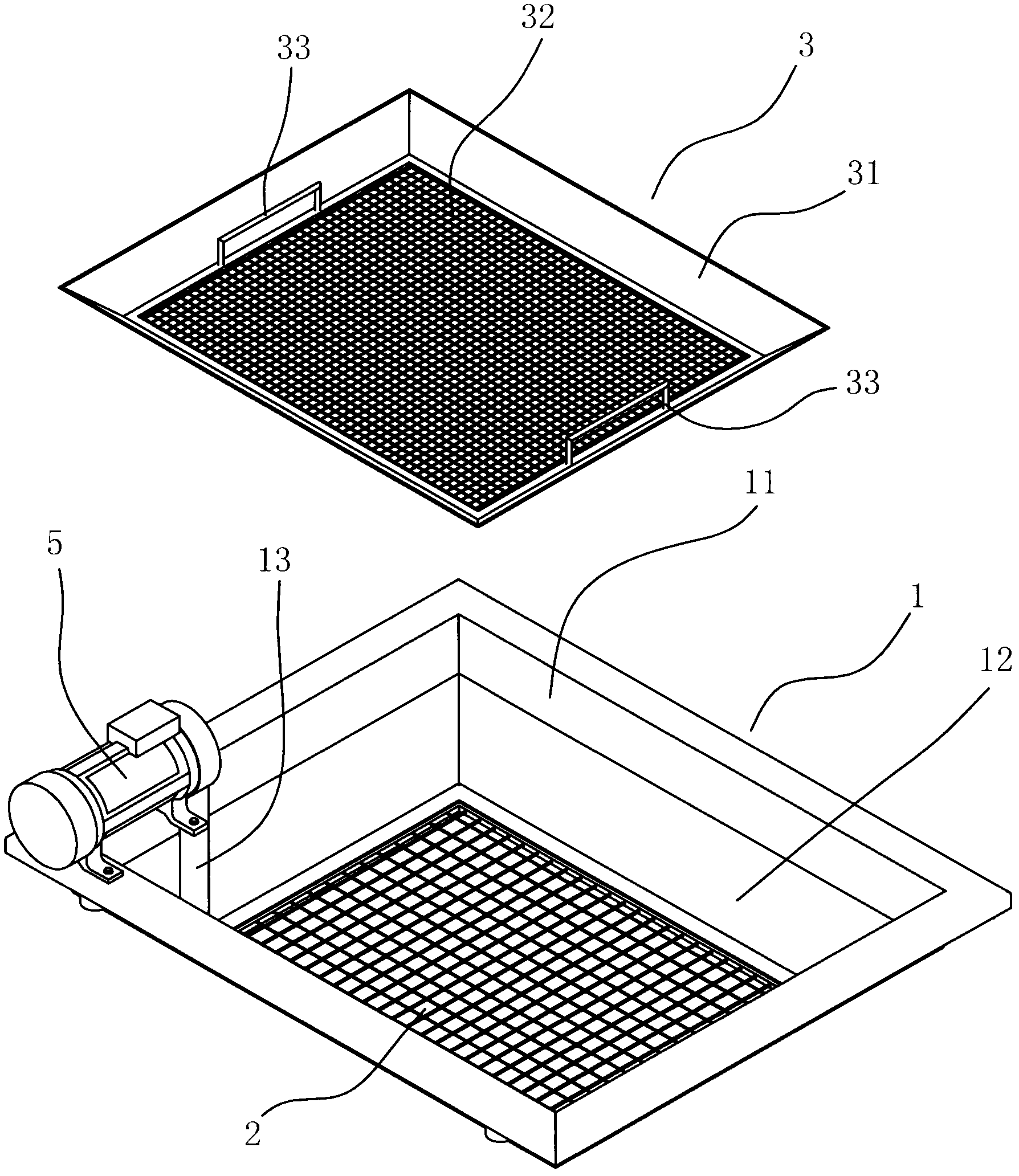

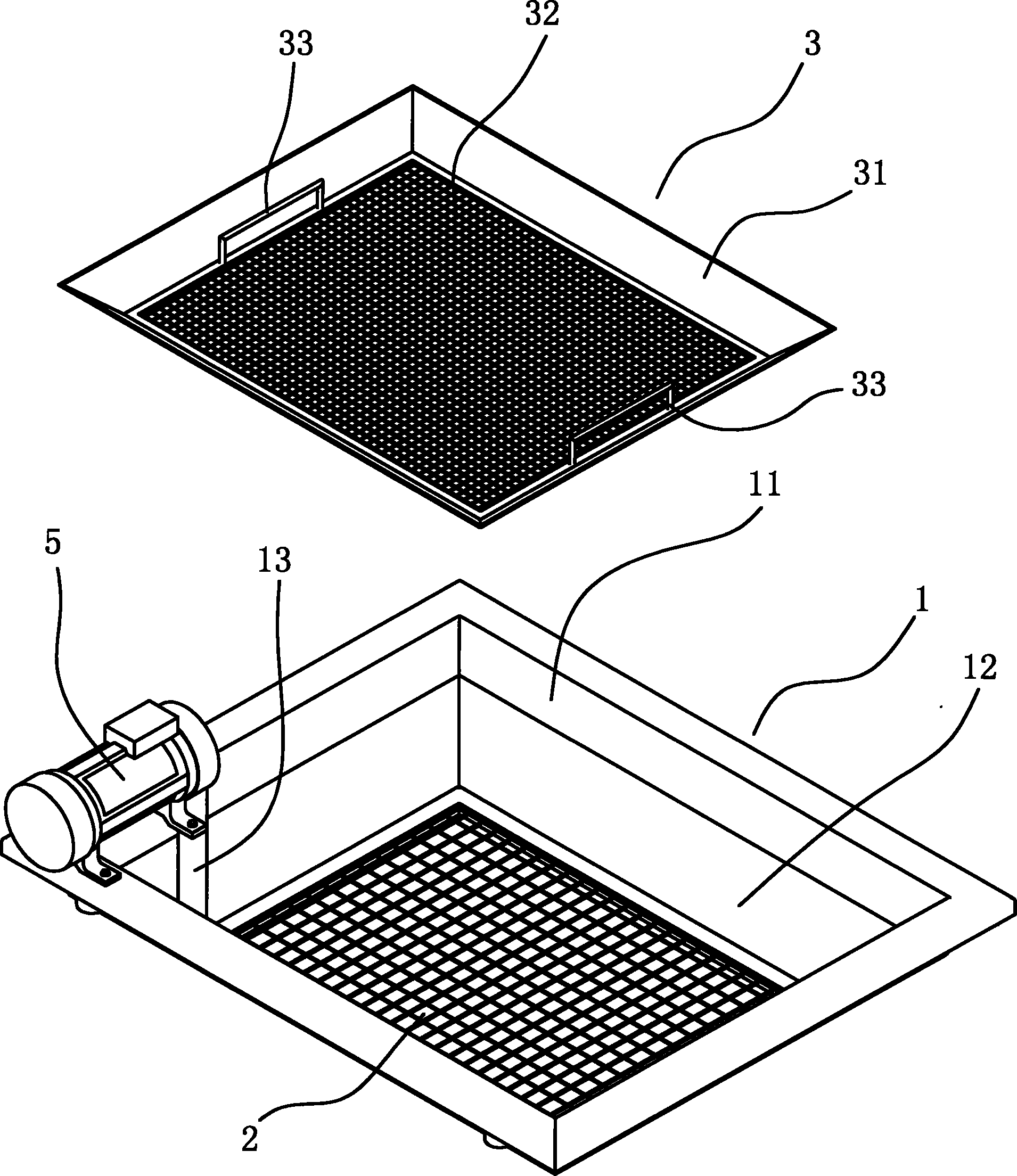

[0021] Example: see figure 1 , a kind of method that prevents that mortar spraying machine from clogging of the present invention, it comprises the following steps:

[0022] (1) Prepare a sieve ash hopper device, which sieve ash hopper device includes an ash hopper 1, a layer of grid layer 2 is set at the discharge opening at the bottom of the ash hopper 1, and the ash hopper 1 is close to the bottom A movable grille layer 3 that can be taken out is set at the position, and an electric vibrator 5 is fixed on the ash hopper 1. The hole size in the movable grille layer 3 is smaller than the hole size in the grille layer 2;

[0023] (2) the sieve ash hopper device is installed above the ash tank of the mortar sprayer by an elastic member, so that the mortar material entering the mortar sprayer is first filtered by the sieve ash hopper device;

[0024] (3) Start the electric vibrator 5 on the sieving ash hopper device when the mortar spraying machine is working, so that the ash h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com