Pressure transfer eccentric water distribution blanking plug

A technology of eccentric water distribution and plugging, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve problems such as interlayer channeling, high labor intensity, and inability to meet the needs of stable water injection in separate injection wells, and achieve reduction The probability of failure, the simplification of the test process, and the effect of improving the efficiency of test work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

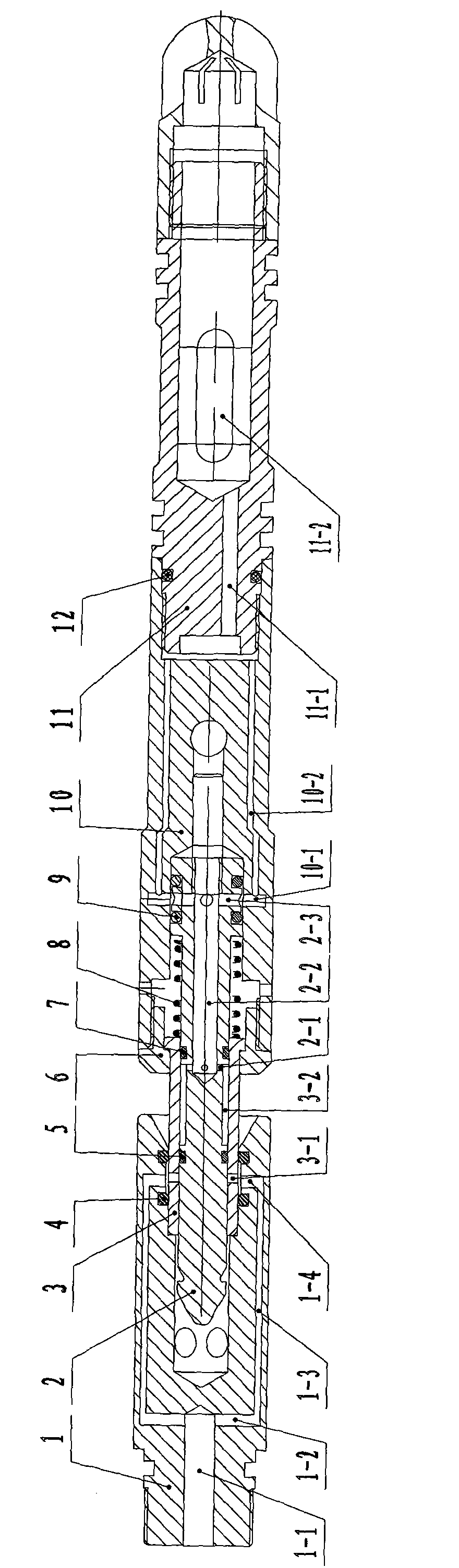

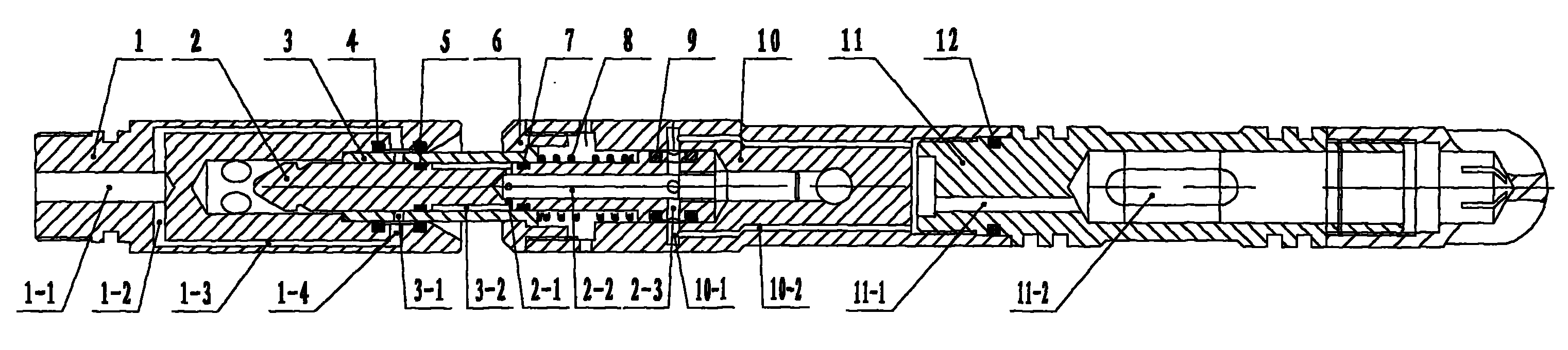

[0017] As shown in the figure, the present invention includes a lower body 11 and an upper body 10 connected with the lower body 11 by threading. The lower main body 11 is provided with three long slots 11-2 for water injection, and the lower main body 11 is provided with a pressure transmission hole I11-1 along the axial direction. The pressure transmission hole I11-1 can communicate with the inner working chamber at both ends of the lower main body 11 , the flow pressure of the target layer can enter the working cavity at the other end through the pressure transmission hole I11-1 of the lower body 11, which is the first channel for pressure transmission in the present invention. In addition, a lower main body sealing ring 12 may also be provided in the sealing groove of the lower main body 11 .

[0018] The upper body 10 is provided with a pressure transmission hole II10-2 along the axial direction. It should be noted that during preparation, the pressure transmission hole I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com