Outer cylinder side opening type multistage depressed collector component and manufacturing method thereof

A collector and side-opening technology, which is applied in the field of outer cylinder side-opening multi-stage step-down collector components, can solve the problems of ceramic pollution and insulation decline, and achieve the effect of ensuring stability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

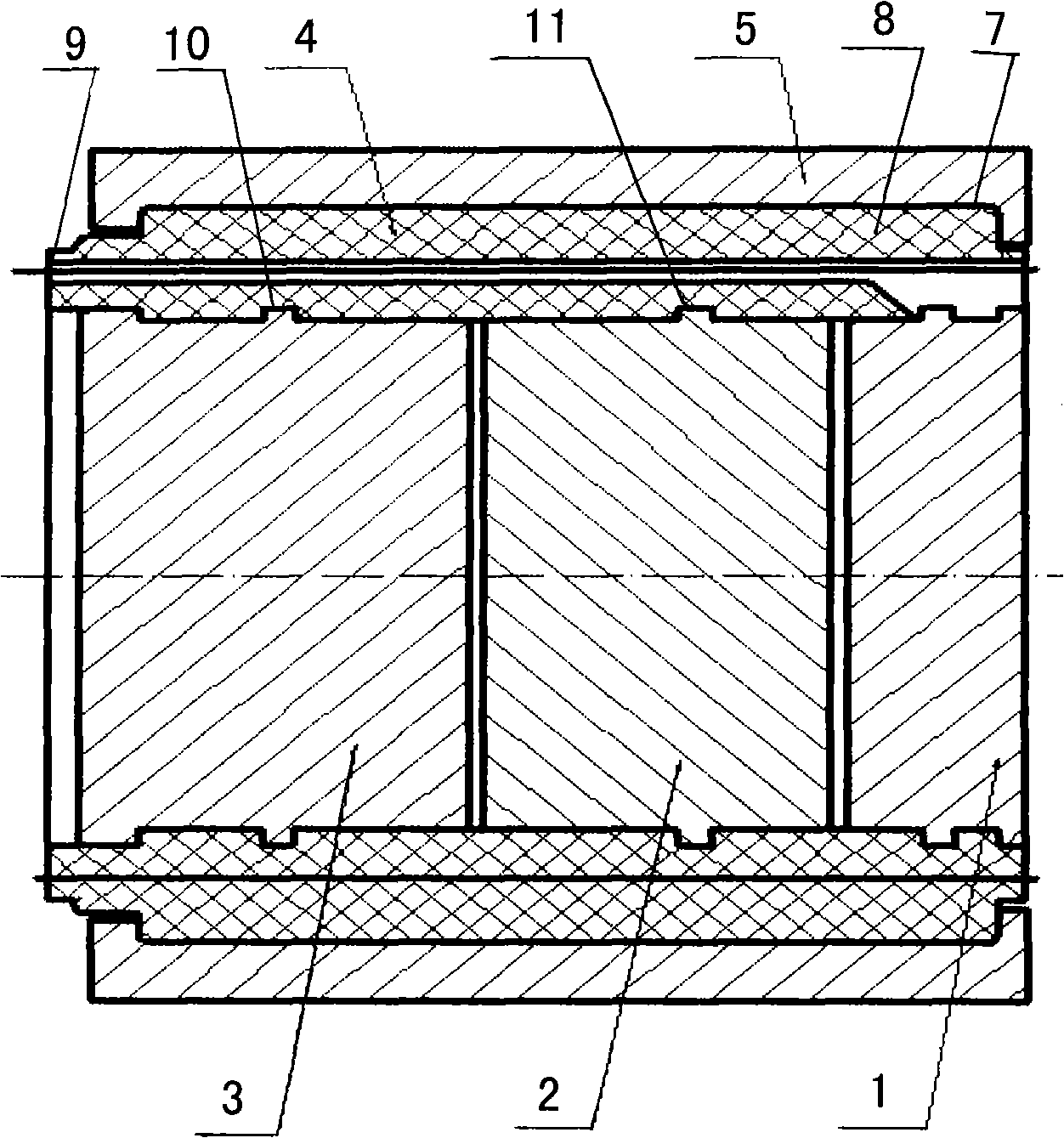

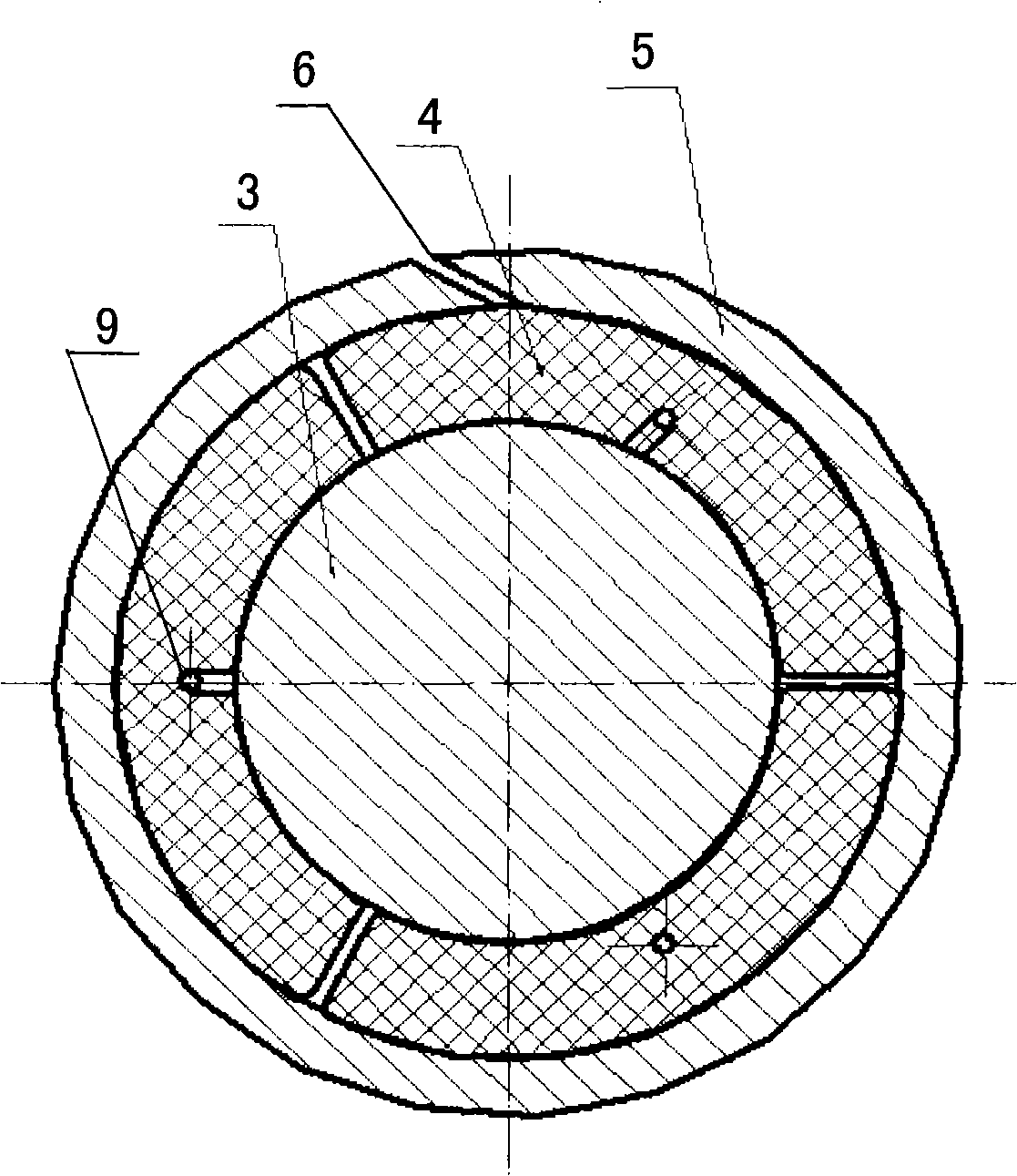

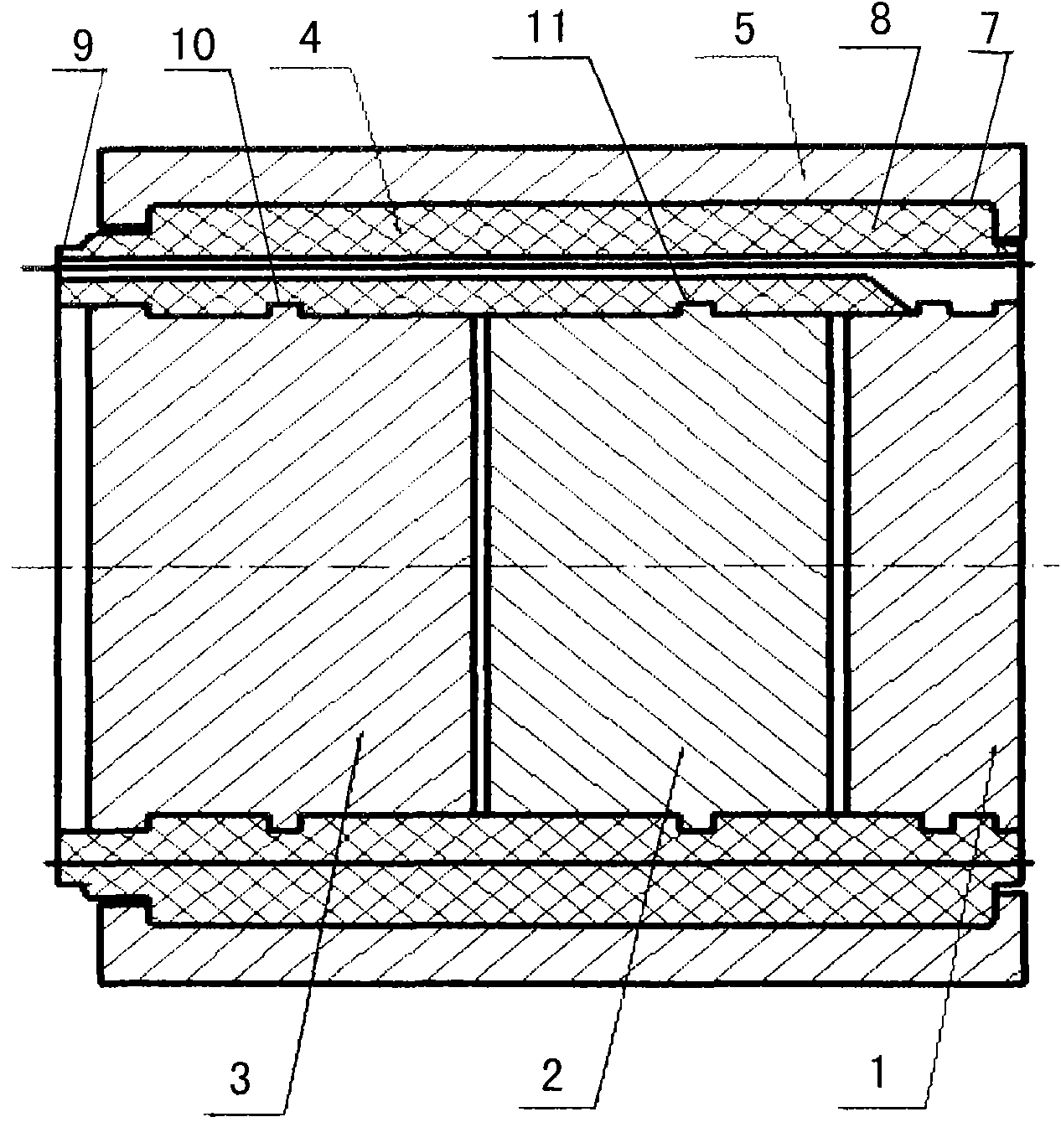

[0029] The outer cylinder side opening type multi-stage step-down collector assembly and the manufacturing method of the present invention are to divide the entire beryllium oxide ceramic cylinder into N / N arcs according to the number of collector stages N, and then combine them into a complete cylinder. Slots are made on the beryllium ceramic cylinder to locate the electrodes, and holes are drilled in the ceramic to carry the lead wires of the collectors; the ceramics are required to be tightly matched with the electrodes of the collector and the outer sleeve of the collector; the side of the outer cylinder of the collector is opened obliquely, so that The outer cylinder of the collector can be opened larger. After the ceramics and the electrodes of the collector are loaded into the outer cylinder, solder is placed at the opening, and a molybdenum cylinder is covered; the whole is put into a furnace for heating, and the molybdenum cylinder with a low expansion coefficient combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com