Vibrating mechanism with stepless adjustable eccentric moment

A technology of eccentric moment and vibration mechanism, applied in the direction of fluid using vibration, can solve the problems of poor controllability, large mechanism, easy damage of transmission parts such as gears, etc., to improve work efficiency and work adaptability, broad market application prospects, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

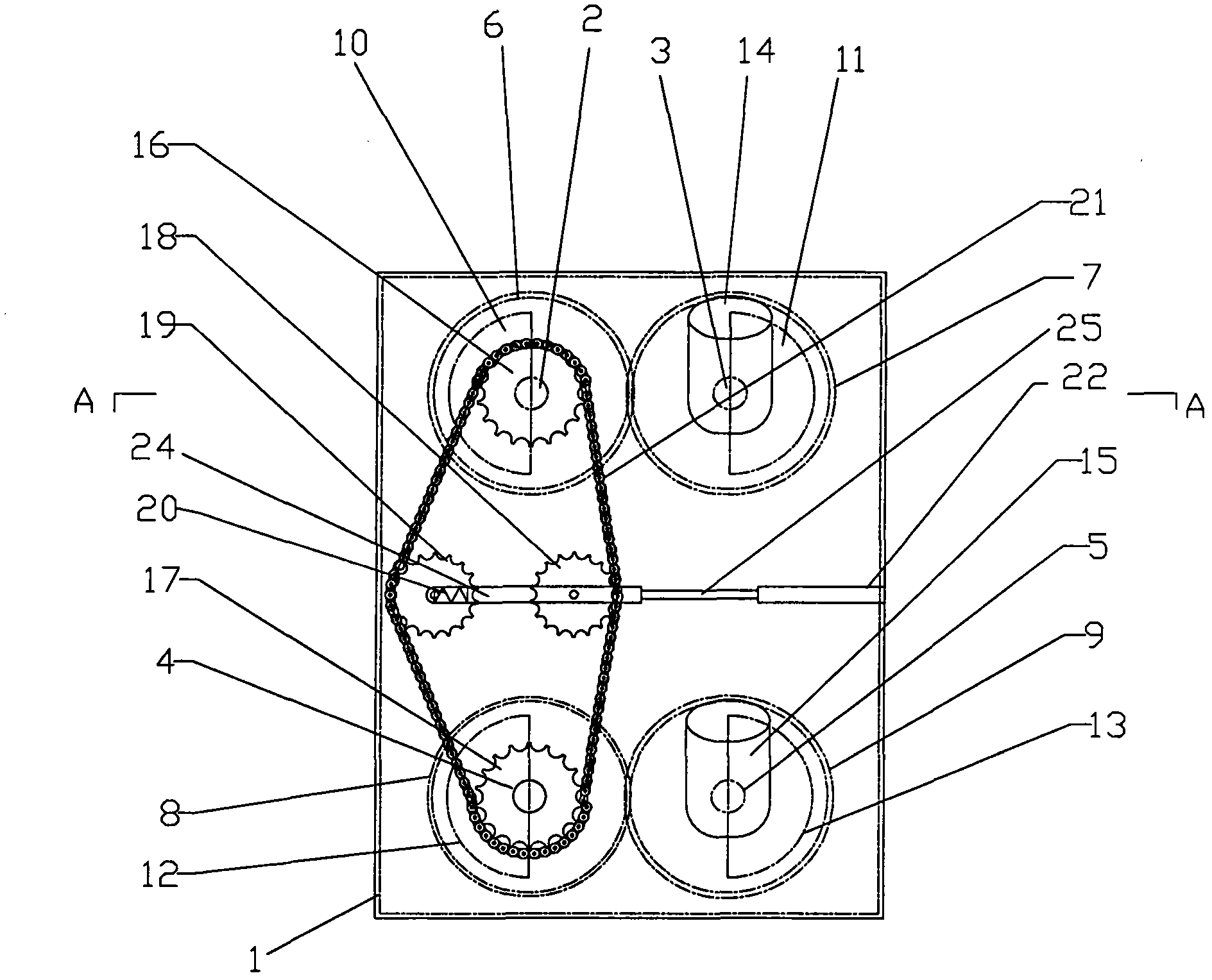

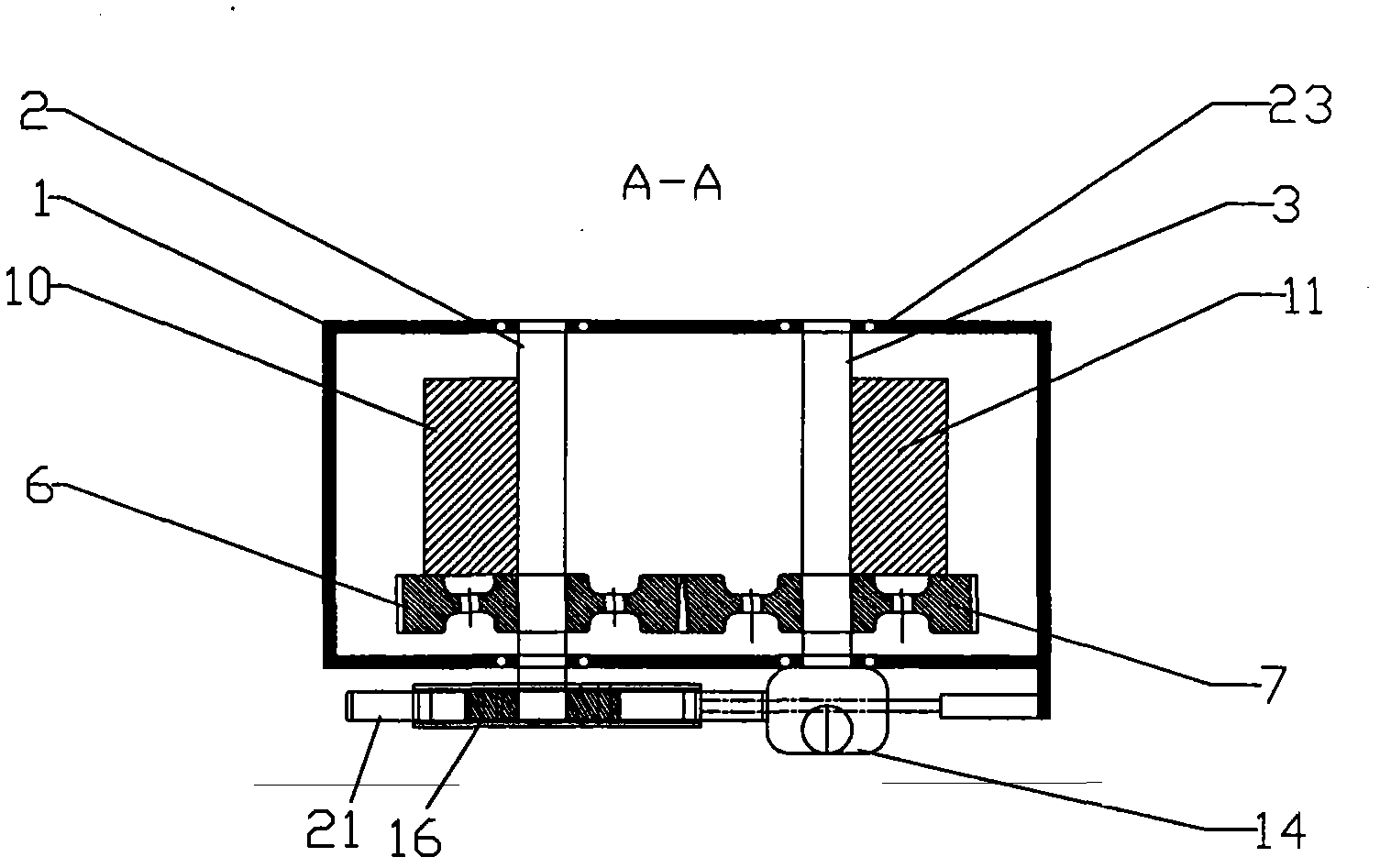

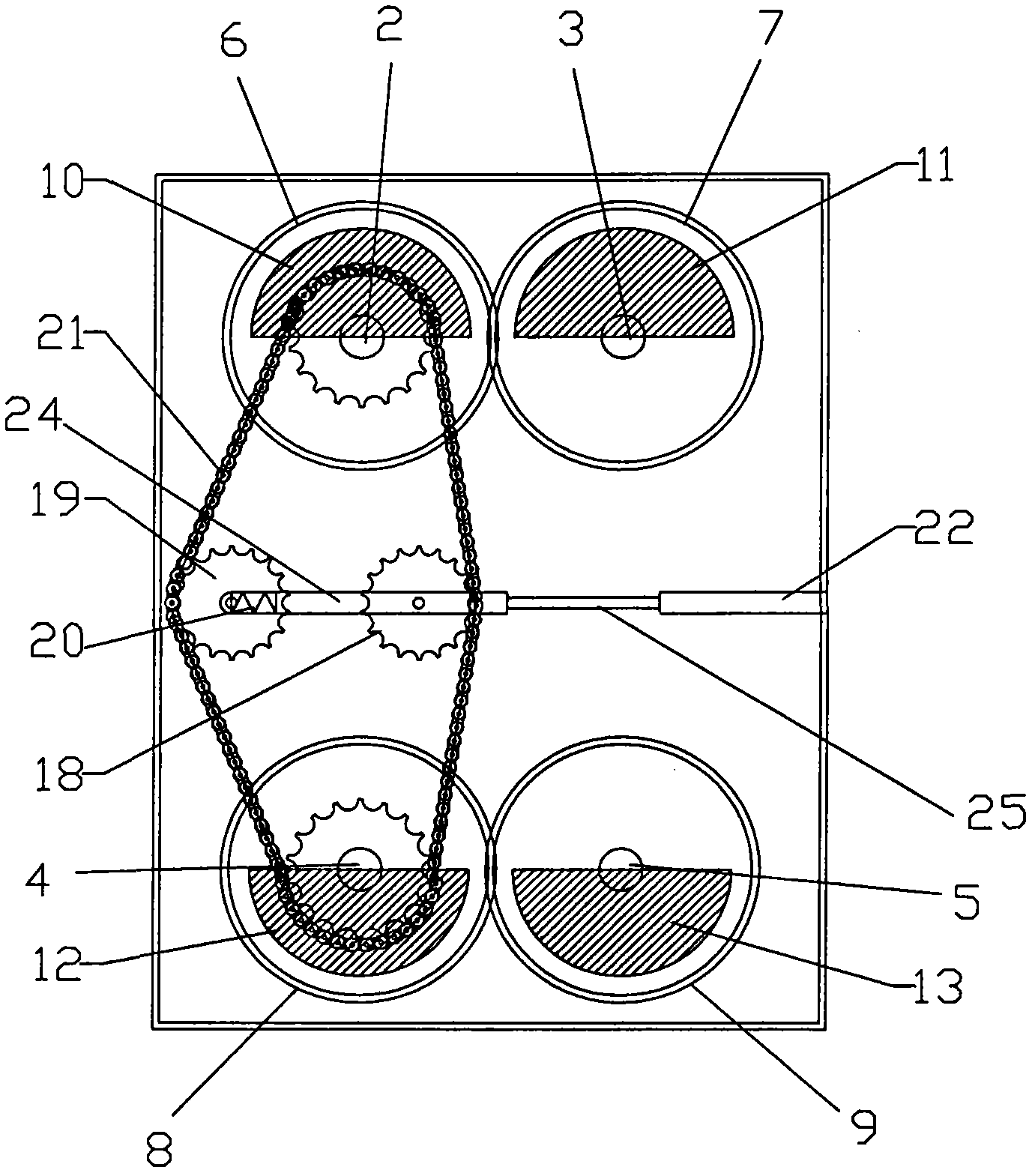

[0014] Below in conjunction with accompanying drawing, the present invention will be further described:

[0015] The upper part of the box body 1 is installed with the first eccentric shaft 2 and the second eccentric shaft 3 side by side, the first eccentric shaft 2 and the second eccentric shaft 3 constitute the upper eccentric group, and the lower part of the box body 1 is installed with the third eccentric shaft side by side 4 and the fourth eccentric shaft 5, the third eccentric shaft 4 and the fourth eccentric shaft 5 constitute the lower eccentric group, and the above four eccentric shafts are all connected to the box body 1 through the bearing 23; the eccentric block 10 is installed on the first eccentric shaft 2 , gear 6 and upper sprocket 16, eccentric block 11 and gear 7 are installed on the second eccentric shaft 3, gear 7 is connected with hydraulic motor 14, gear 7 is meshed with gear 6; eccentric block 4 is installed on the third eccentric shaft 4 Block 12, gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com