Method for removing burr from combined hole and forming method and equipment for combined hole

A technology of combining holes and burrs, used in drilling/drilling equipment, metal processing equipment, components of boring machines/drilling machines, etc., can solve problems such as low efficiency, unsuitable for low-cost and mass production, and large labor costs. , to achieve the effect of simple production, high pass rate, and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

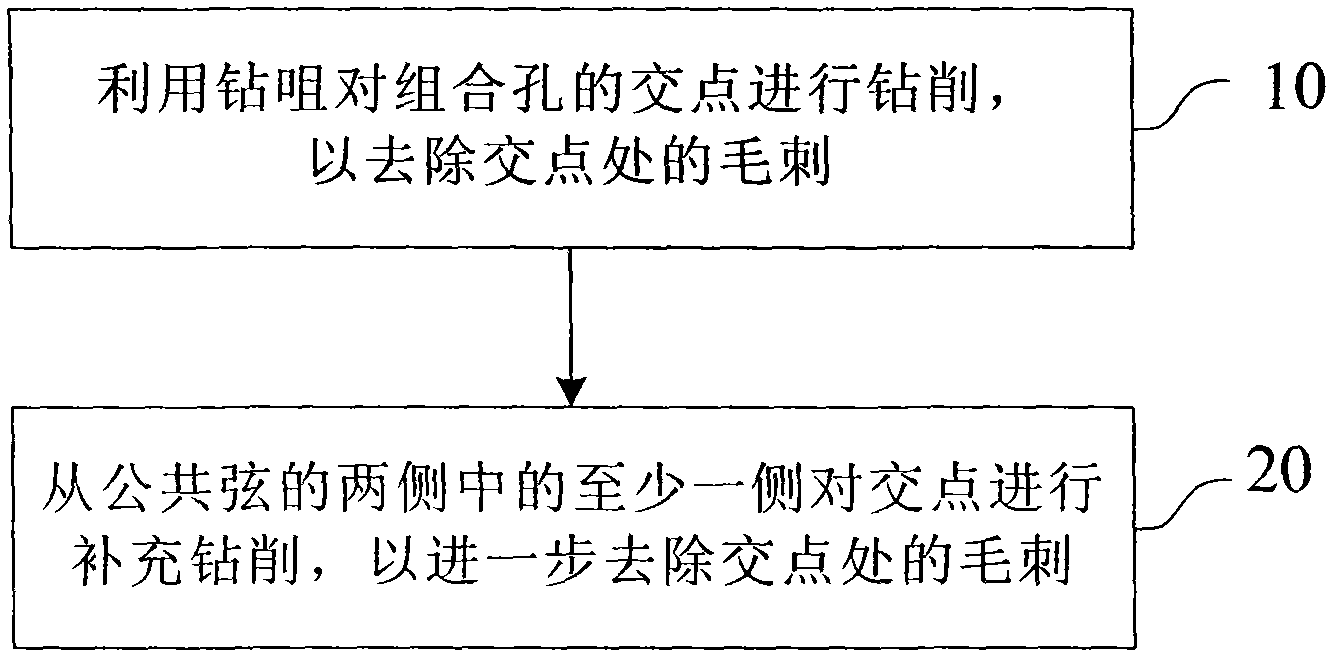

[0030] The invention provides a method for removing burrs from combined holes. The combined holes include at least two intersecting single holes, and the single holes are round holes or non-round holes or the single holes include round holes and non-round holes. The intersection of adjacent two single holes defines a common chord, wherein the method comprises the steps of:

[0031] Step 10): Drilling the intersection point with a drill bit to remove burrs at the intersection point.

[0032] Preferably, in each embodiment of the present invention, the step 10) includes:

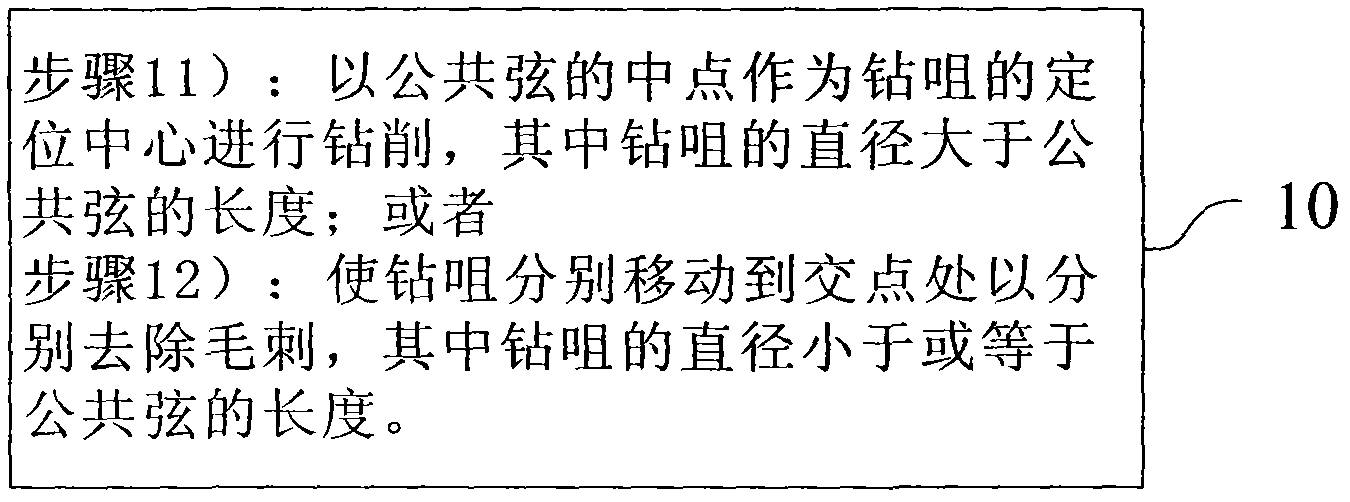

[0033] Step 11): Drilling with the midpoint of the common chord as the positioning center of the drill bit, wherein the diameter of the drill bit is greater than the length of the common chord;

[0034] or

[0035] Step 12): Move the drills to the intersection points to remove the burrs respectively, wherein the diameter of the drills is less than or equal to the length of the common chord.

[0036] Prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com