Hermetic mems device and method for fabricating hermetic mems device and package structure of hermetic mems device

A micro-electro-mechanical system and packaging structure technology, applied in the direction of micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problems of production yield and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

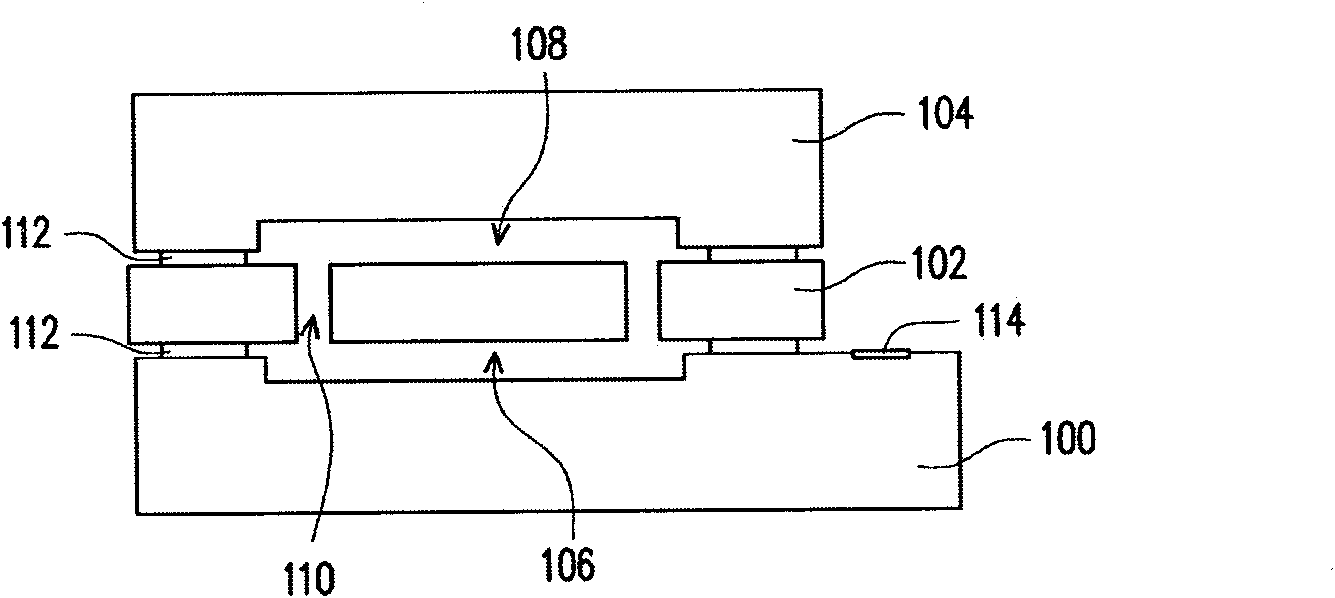

[0039] In the present disclosure, novel sealed MEMS devices in several embodiments have been proposed. The sealed MEMS package has at least the following characteristics. Integration between IC and MEMS increases high performance. The MEMS and the sensing IC are fabricated in the same substrate to avoid parasitic effects of combining the MEMS with the sensing IC. The encapsulation layer may be formed over one side of the MEMS element by an interconnect process known from CMOS technology. Chip scale package (CSP) and wafer level package (WLP) are available for small size and low cost processes. An additional substrate is attached to the other side of the MEMS using wafer-to-wafer bonding or fusion to form a hermetic package.

[0040] Several examples are provided for description. However, the present invention is not limited to the disclosure of the embodiments. In addition, the embodiments can also be appropriately combined with each other.

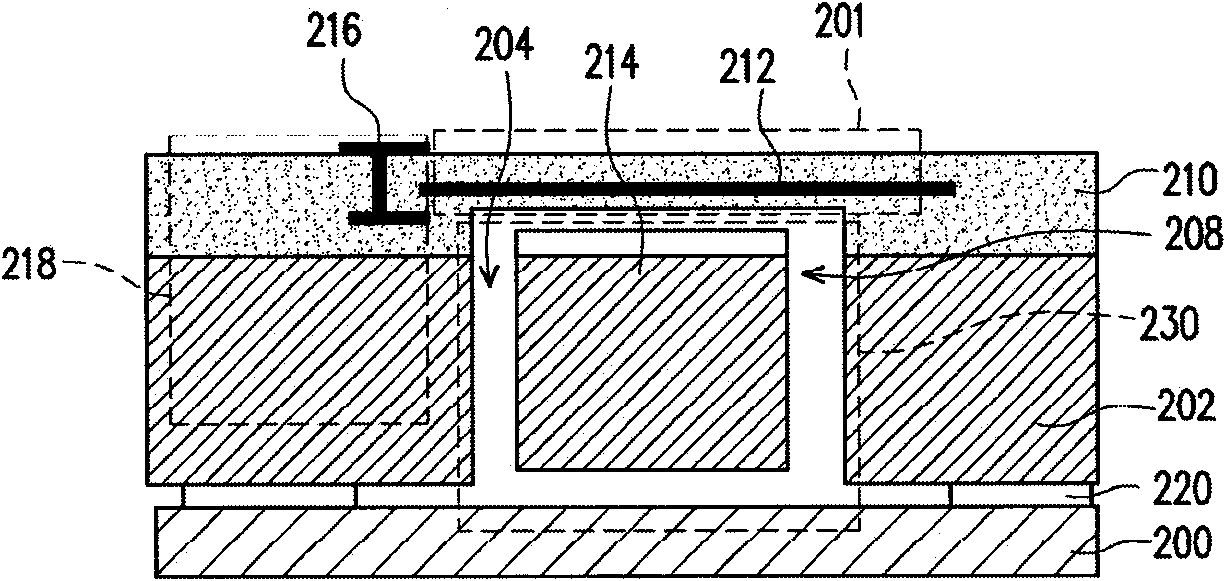

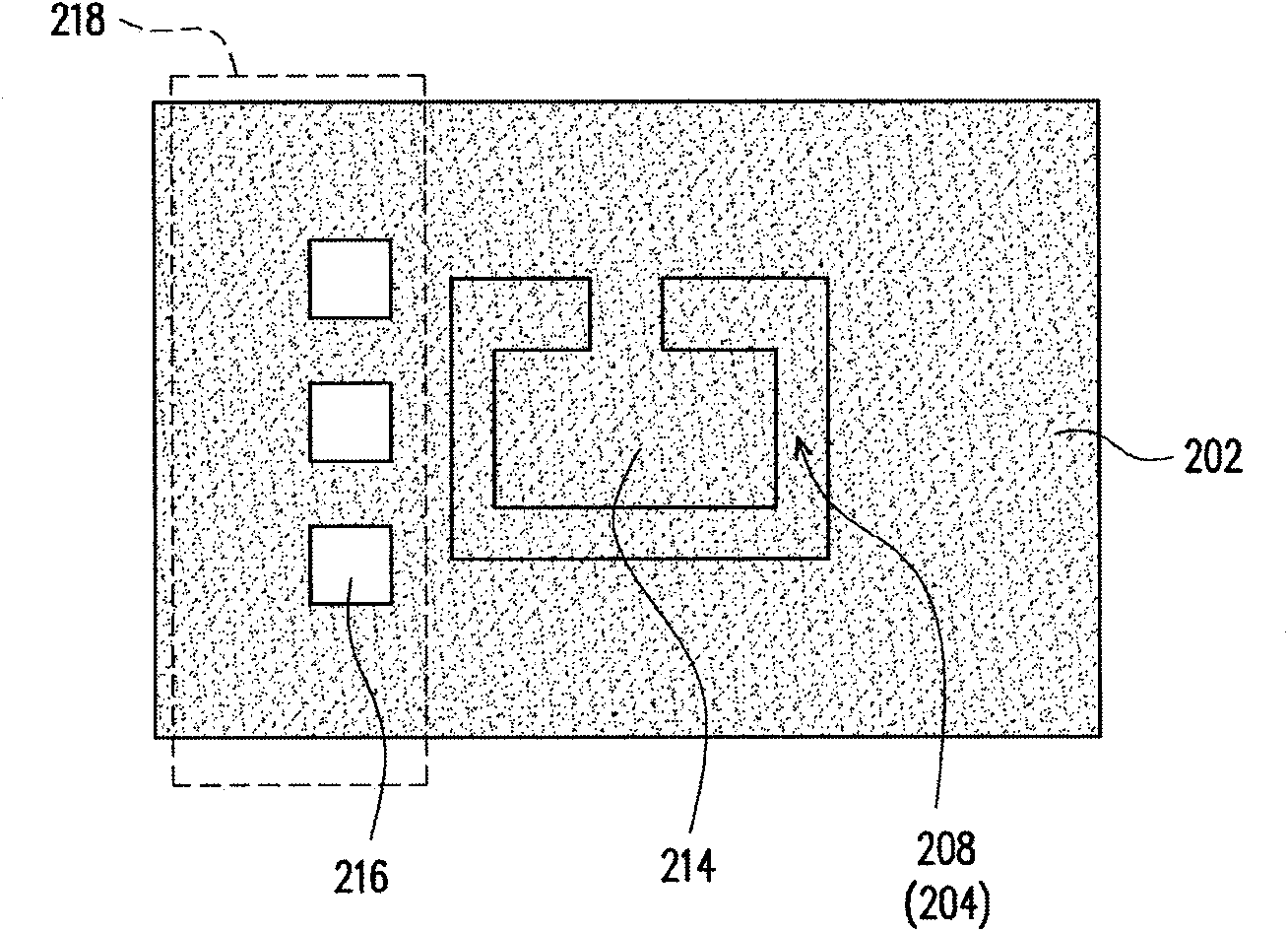

[0041] Figure 2A is a cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com