Rubber composition for tire tread and tire manufactured using the same

A technology of rubber composition and tire tread, which is applied in the field of rubber composition for tire tread and tires made of it, which can solve problems such as reduced safety, achieve optimized low-temperature characteristics, optimize fuel consumption performance, and have good environmental protection effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

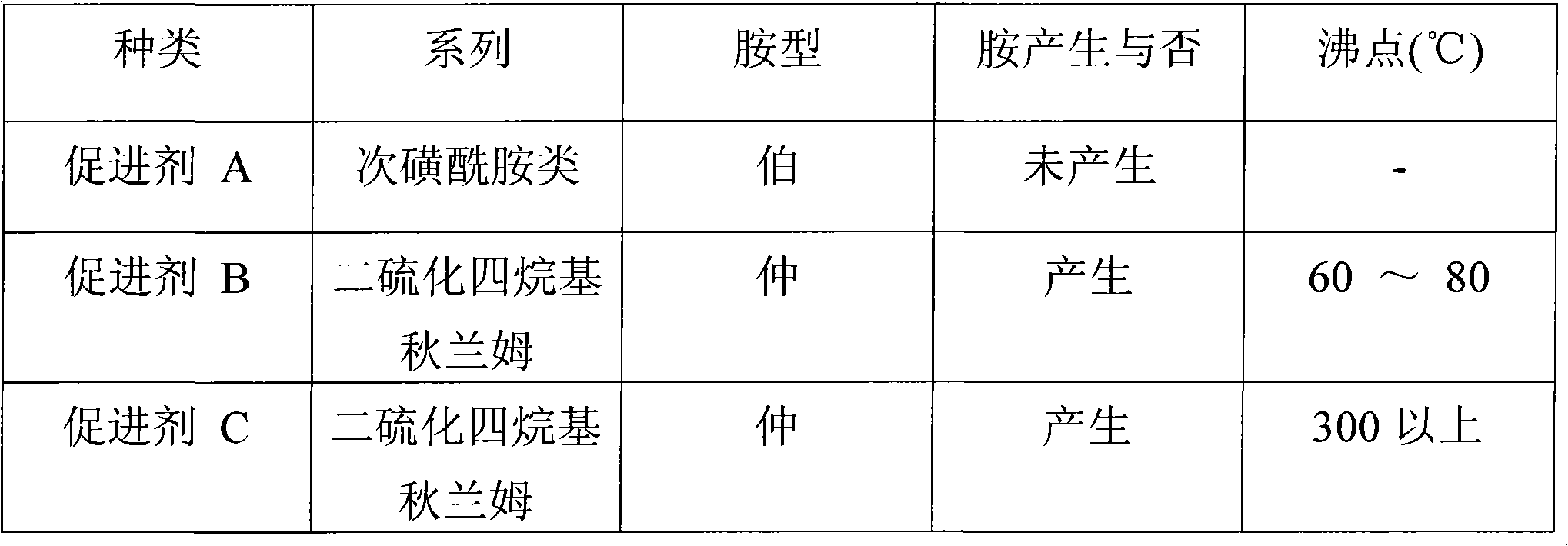

Image

Examples

Embodiment Construction

[0055] Below, the embodiments of the present invention will be described in detail, so that those skilled in the art can easily implement the present invention. However, the present invention can be embodied in various forms, and is not limited to these examples.

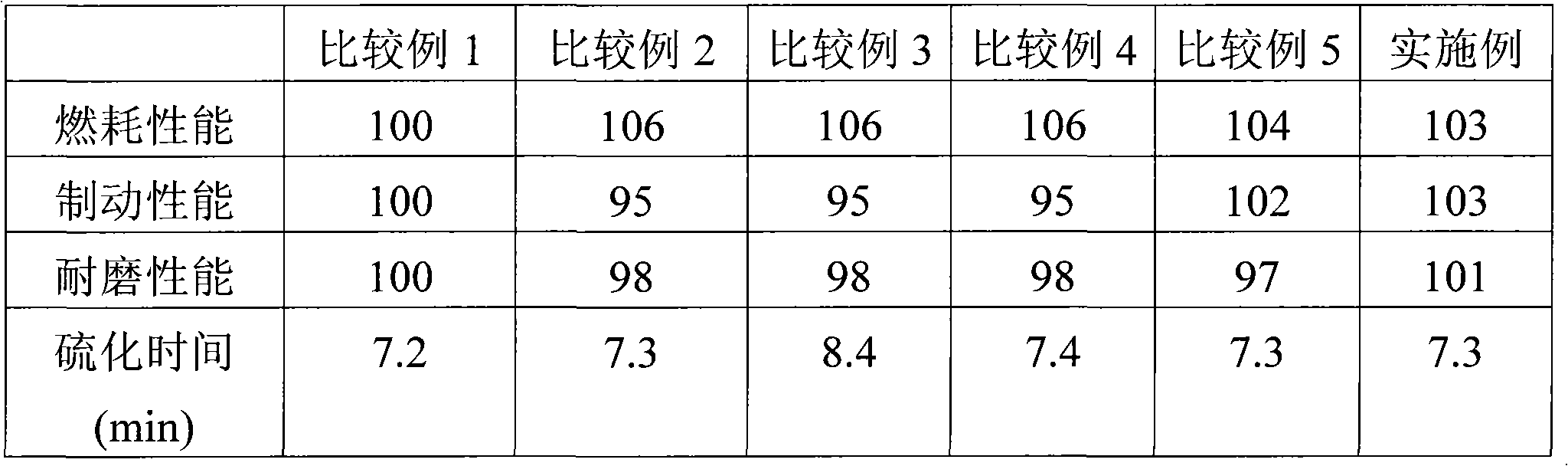

[0056] Production Example: Production of Rubber Composition

[0057] Rubber compositions for tire treads according to Examples and Comparative Examples were prepared using the compositions in Table 1 below. The rubber composition for tire treads is manufactured using a conventional tire tread rubber manufacturing method.

[0058] [Table 1] (unit: parts by weight)

[0059]

Comparative example 1

Comparative example 2

Comparative example 3

Comparative example 4

Comparative Example 5

Example

E-SBR A (1)

100(137)

-

-

-

-

-

E-SBR B (2)

-

100(137)

100(137)

100(137)

100(137)

100(137)

filler (3)

70 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com