Method and structure used in hydraulic engineering for maintaining steel wire ropes

A water conservancy project and steel wire rope technology, which is applied in the field of steel wire rope maintenance, can solve the problems of steel wire ropes such as complex stress, short maintenance cycle, and reduced service life, so as to avoid sand and dust pollution and corrosion, improve use safety, and increase service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

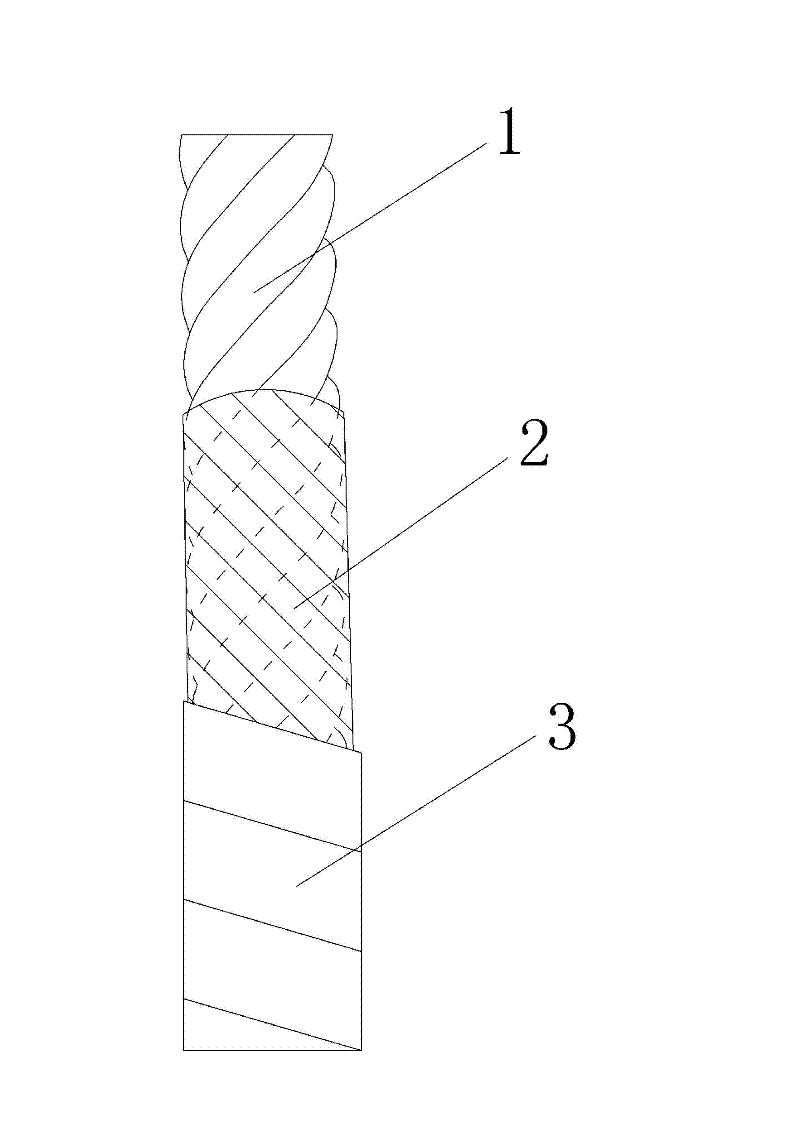

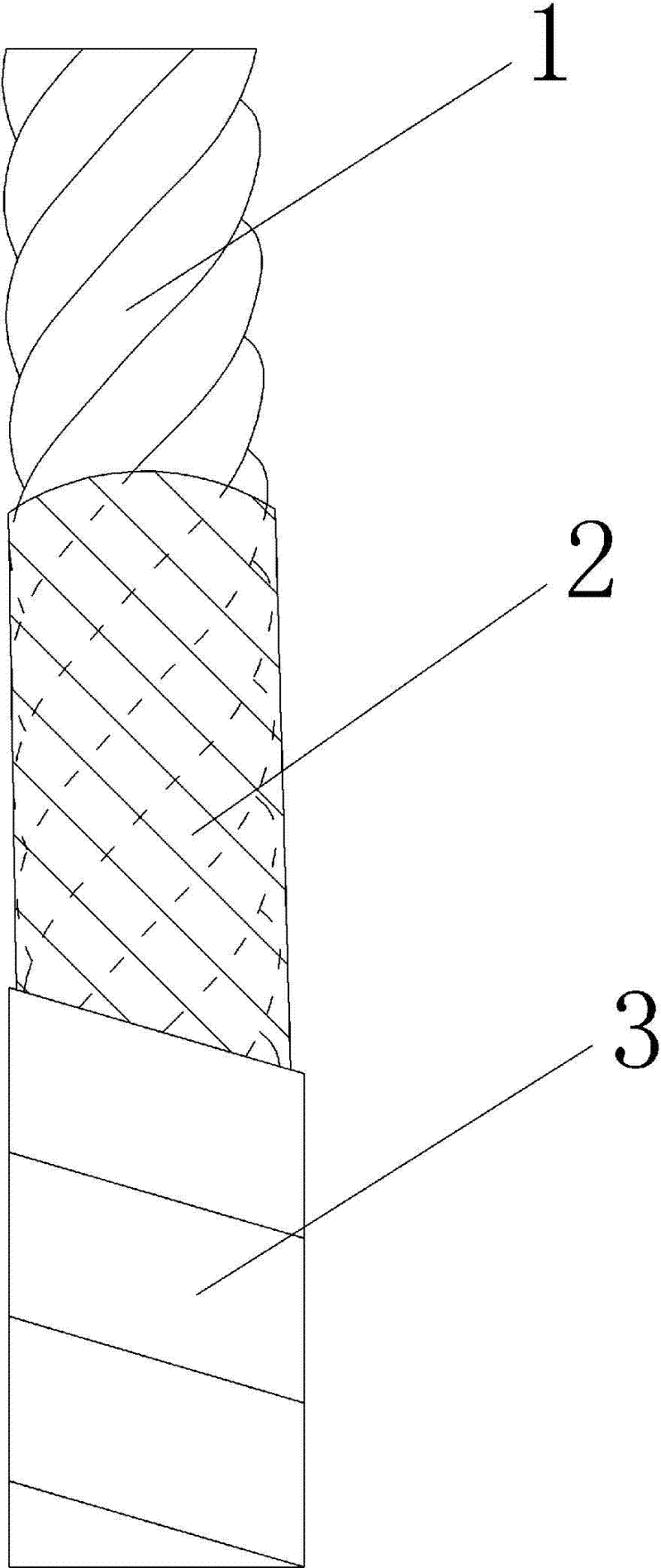

Image

Examples

Embodiment 1

[0018] The steel wire rope maintenance method of the water conservancy project of the present embodiment is as follows:

[0019] 1) Clean the steel wire rope to be maintained with kerosene first, and let it dry naturally;

[0020] 2) Put a certain weight of diesel lubricating oil into an open container and heat it at a temperature of 40-60°C. According to the weight ratio of calcium-based lubricating grease: diesel lubricating oil = 1:4, divide the calcium into several times. Slowly add the base lubricating grease into the diesel engine lubricating oil, and stir while adding, until the calcium-based lubricating grease is completely dissolved in the diesel engine lubricating oil to prepare a mixed lubricating material;

[0021] 3) Apply the prepared mixed lubricating material evenly on the steel wire rope after step 1) while it is hot. It can be painted several times so that the mixed lubricating material can be impregnated into the inside of the steel wire rope as much as poss...

Embodiment 2

[0025] The steel wire rope maintenance method for water conservancy projects in this embodiment is basically the same as that in Embodiment 1, except that the weight ratio of calcium-based lubricating grease to diesel lubricating oil is 1:3.

Embodiment 3

[0027] The steel wire rope maintenance method for water conservancy projects in this embodiment is basically the same as that in Embodiment 1, except that the weight ratio of calcium-based lubricating grease to diesel engine lubricating oil is 1:3.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com