Shaft equipment mounting construction platform

A construction platform and equipment technology, applied in shaft equipment, mining equipment, earthwork drilling and mining, etc., can solve problems such as hidden safety hazards, high requirements for installation quality, and multiple types of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

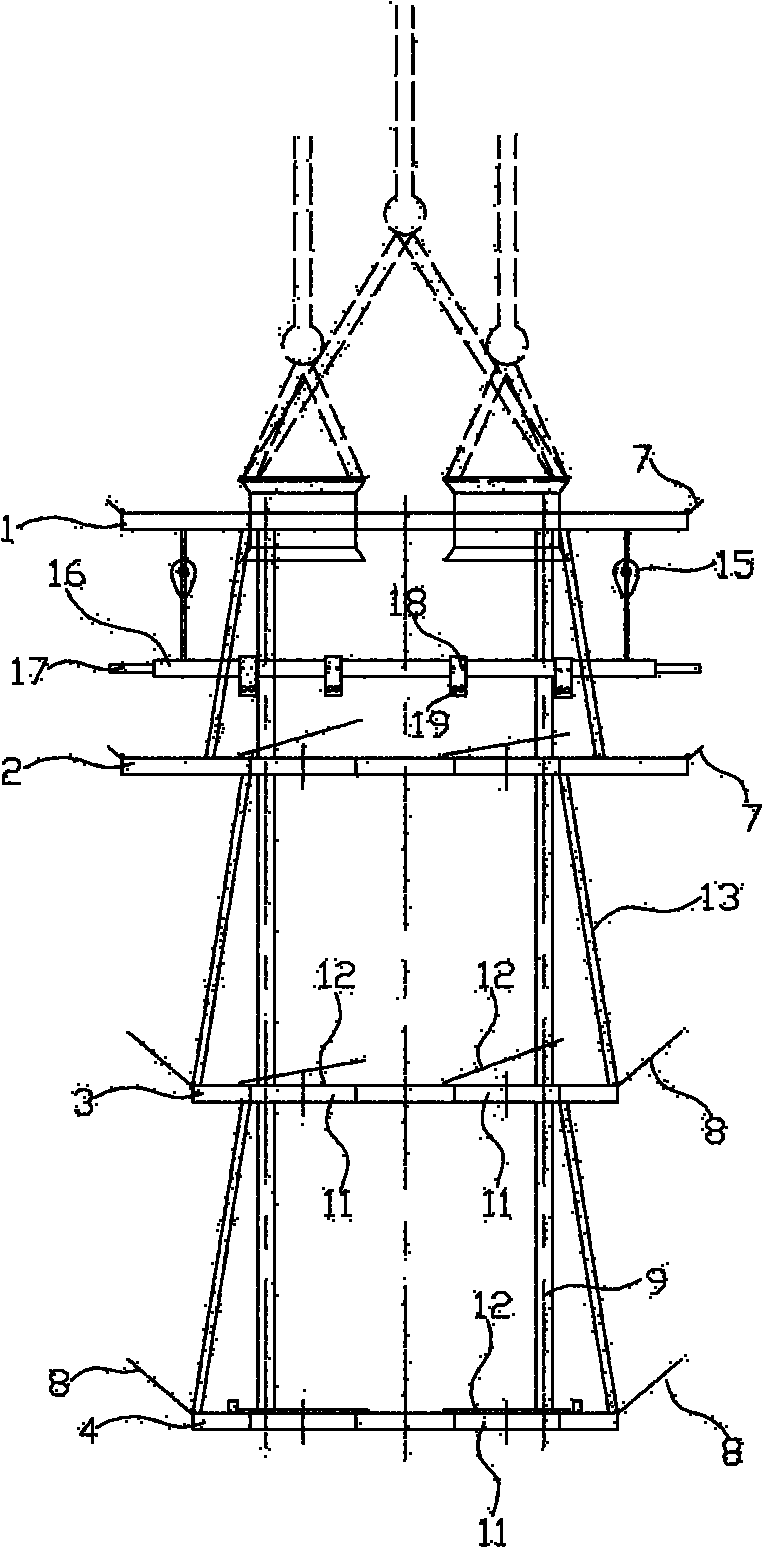

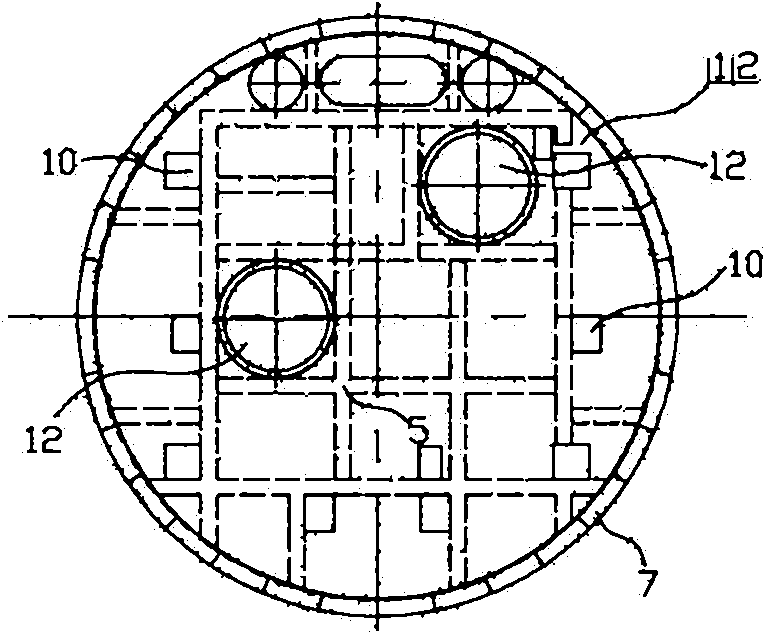

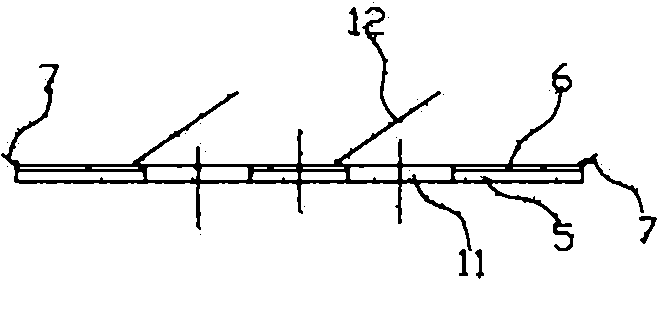

[0023] The present invention is illustrated by the shaft equipment installation and construction platform used when the shaft equipment is installed in a coal mine shaft with an inner diameter of 7.5 meters.

[0024] Figure 1~Figure 8 Among them, the wellbore equipment installation and construction platform has the first and second disc-shaped operating platforms 1 and 2 connected from top to bottom, and the third and fourth square-disk-shaped operating platforms 3 and 4. The adjacent operating platforms The distance between them is compatible with the standard tank road beam layer spacing, which can be 4 to 5 meters. The working platform has a platform skeleton 5, and steel plates 6 are laid on the skeleton. The first and second disc-shaped working platforms are along the Ring fan-shaped plates 7 are hinged on the periphery, and bow-shaped plates 8 are respectively hinged on the four sides of the square disc-shaped work platform. The outer diameter of the disc-shaped work pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com