Method for improving grinding efficiency of test sample of transmission electron microscope

An electron microscope, a technology for testing samples, applied in the field of semiconductor manufacturing, can solve the problems of reducing production efficiency, easily broken samples, difficult to identify samples, etc., to achieve the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

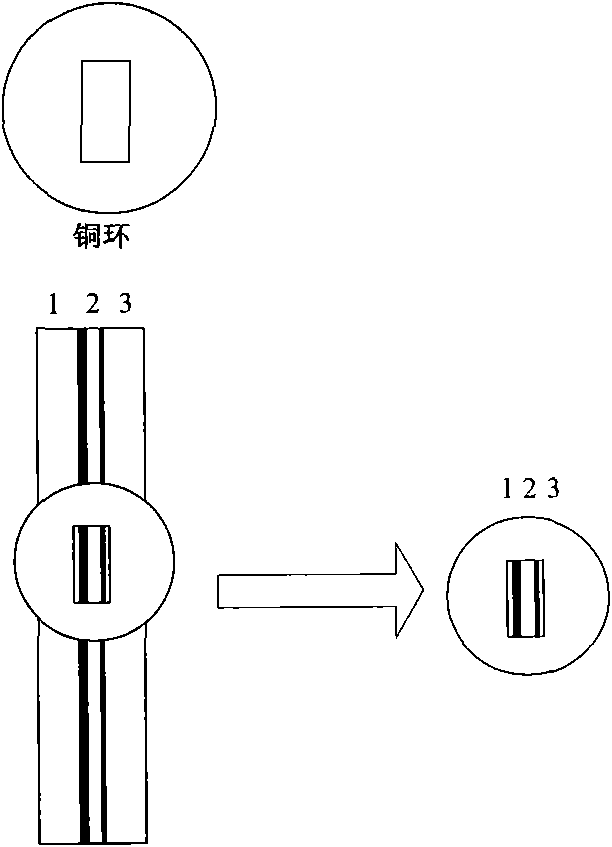

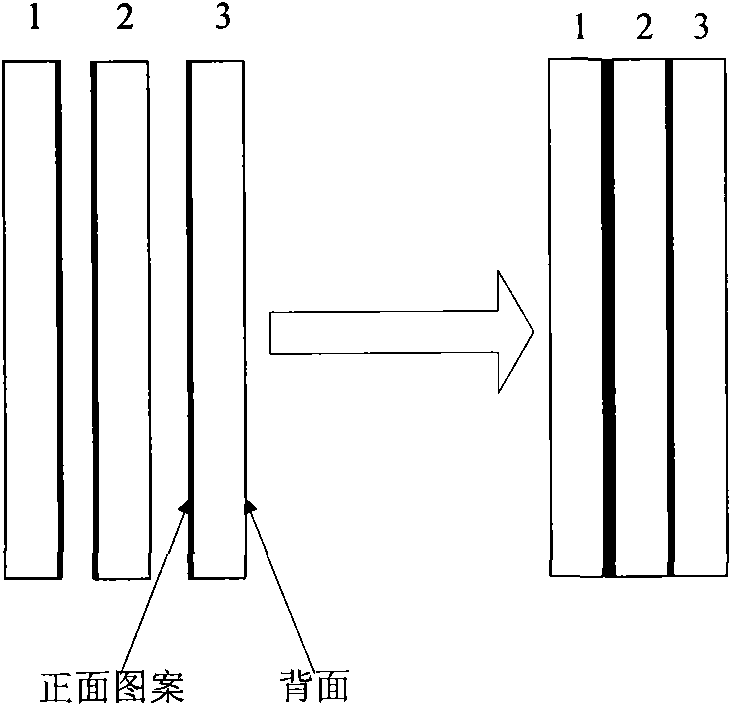

[0026] The core idea of the present invention is: for more than two samples, that is, three or more TEM test samples, it is not necessary to thin the back of the samples, directly paste the samples in order, and then paste a plurality of Cu grid, so that the patterns of all sample TEM tests are reflected in the Cu grid aperture, thereby greatly improving the grinding efficiency of TEM test samples.

[0027] In the specific embodiment of the present invention, the simultaneous grinding of three samples is taken as an example for illustration.

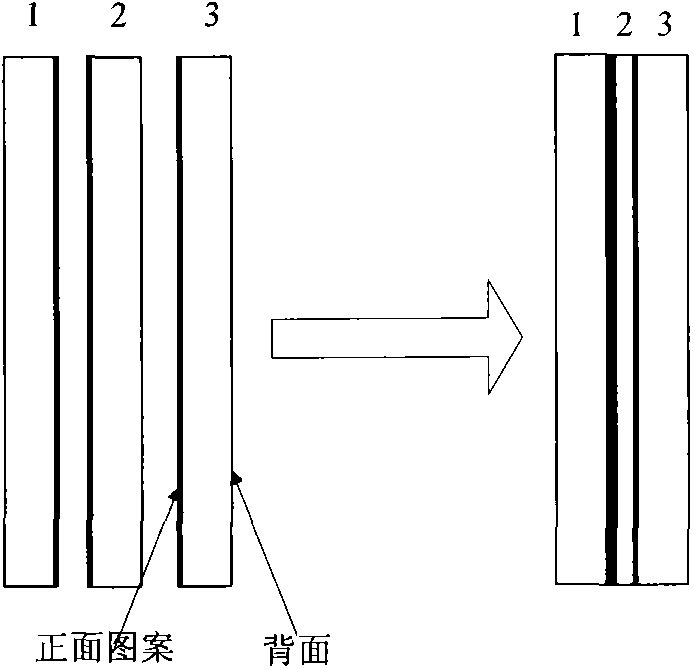

[0028] see Figure 2a , use professional glue to paste samples 1 to 3 on the front or back in order to form a whole. The sample can be any part of the chip that needs to be tested. It is a rectangular (square...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap