Upper anterior tooth resin filler

A filling device and resin technology, applied in dentistry, tooth filling, dental prosthetics, etc., can solve problems such as narrow working surface, long working hours, and poor filling tool effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

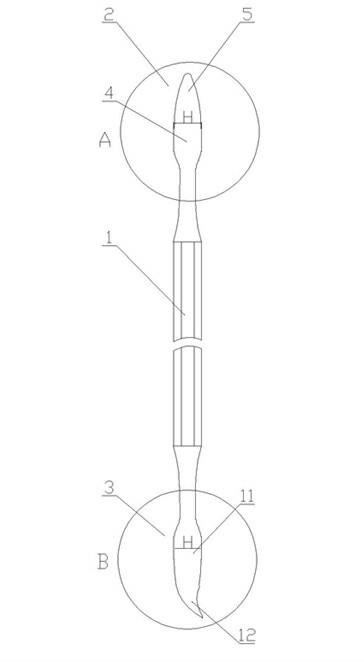

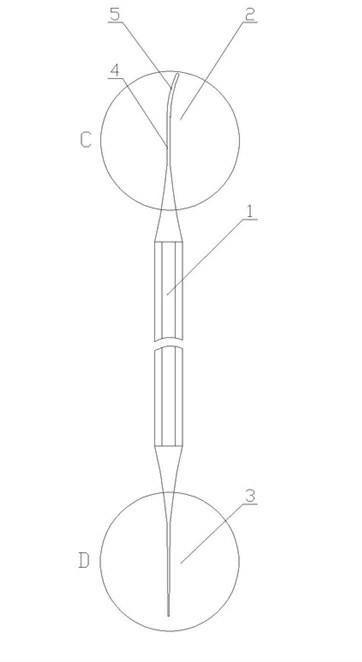

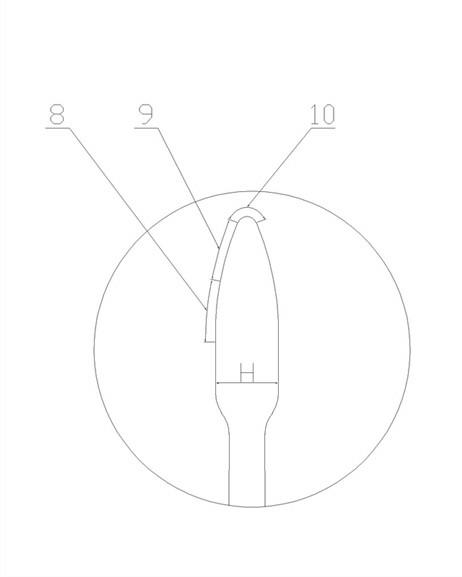

[0013] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 6 Shown: a resin filler for upper anterior teeth, including a shaft 1, an upper filling head 2 and a lower filling head 3 are respectively arranged at both ends of the shaft 1, the upper filling head 2 includes a straight part 4, and The scope of the width H of this straight plate part 4 is: 5-5.5 millimeters, is best with 5.2 millimeters, the scope of thickness D is: 0.3-0.5 millimeter, is best with 0.4 millimeter; The curved part 5, which is different from the straight part 4, is formed by bending to the side of the plane where the straight part 4 is located. The curved part 5 is composed of two smooth transition surfaces, and the two curved surfaces are axially The center line of the section is two smooth transitions and inscribed curves: the first curve 6 and the second curve 7, wherein the range of the curvatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com