Branch crushing machine

A technology of a chipper and a rack, applied in the field of chippers, can solve the problems of easy dumping, high transportation cost, heavy body and other problems, and achieve the effects of avoiding bumps and external damage, reducing noise pollution, and small storage volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

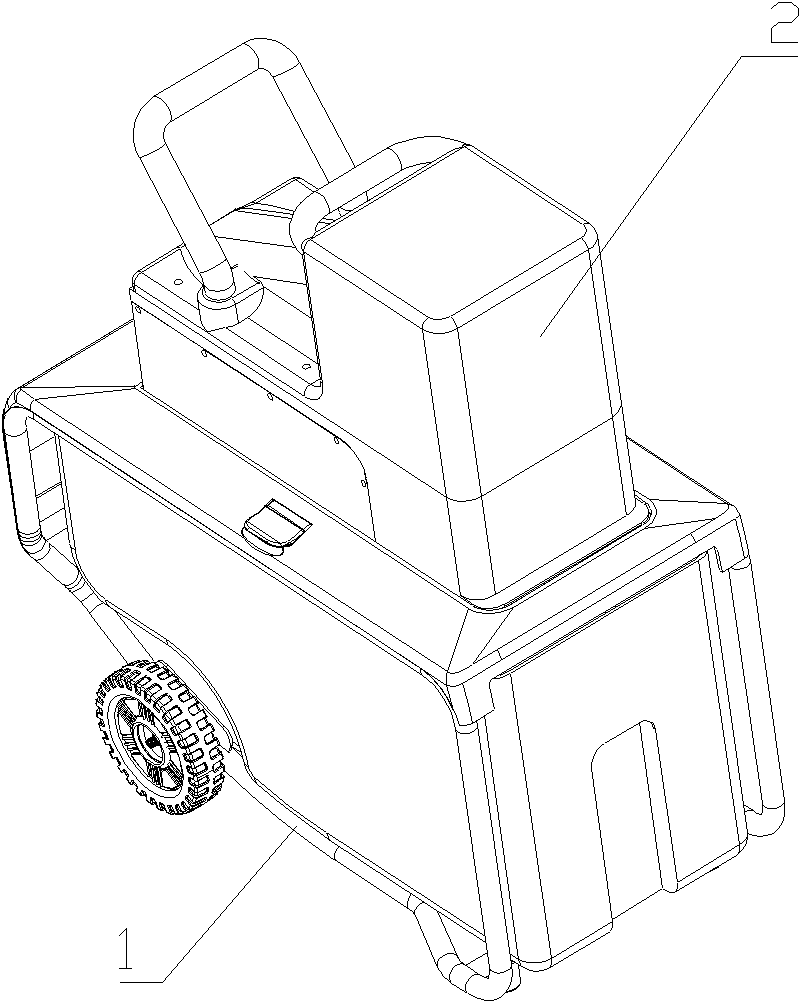

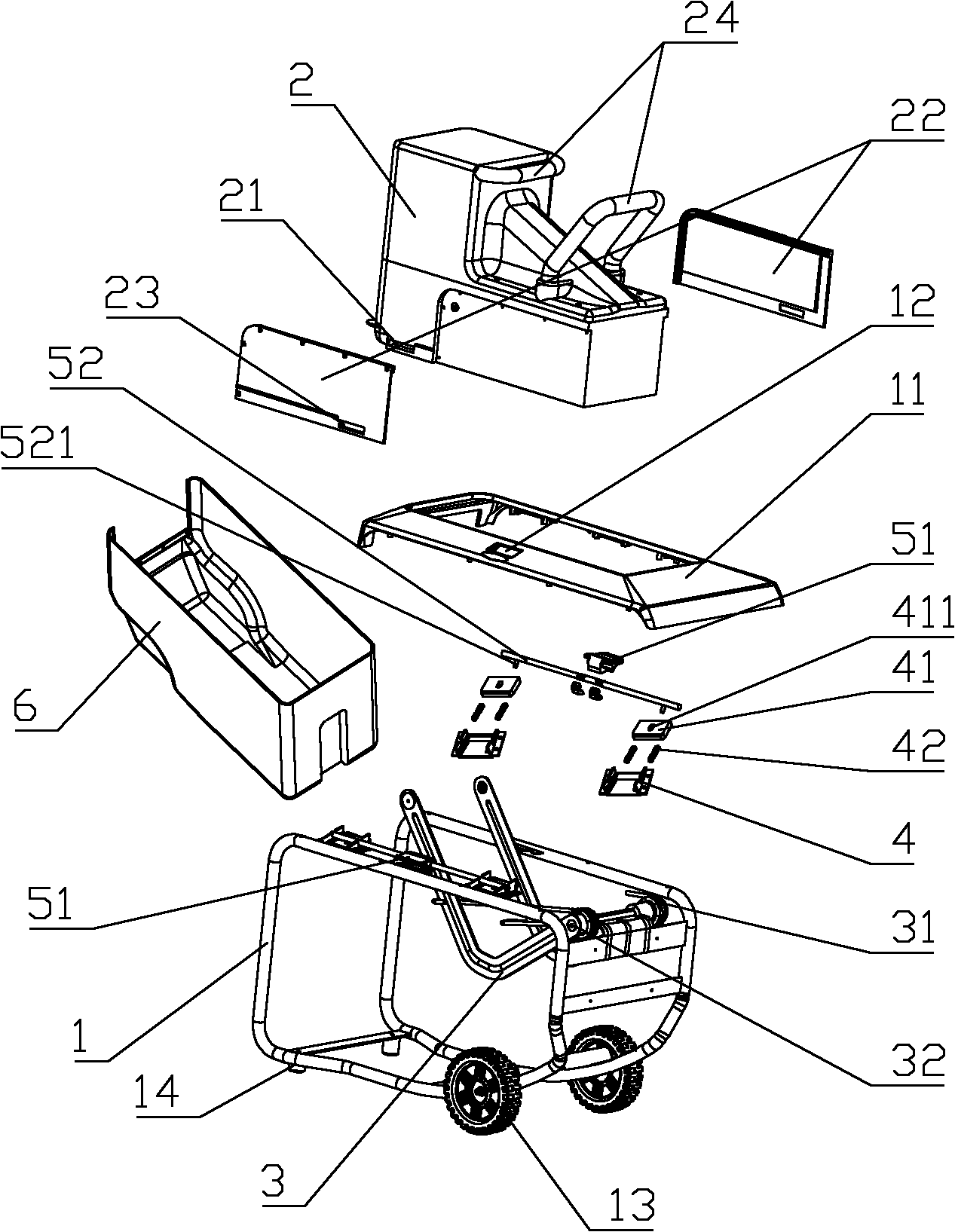

[0021] Such as Figures 1 to 4 Shown is a structural schematic diagram of an embodiment of the present invention, a shredder, including a frame 1 and a body 2 arranged in the frame, the body moves up and down along the frame to realize the conversion between the storage state and the working state, A lifting mechanism for assisting the body to move up and down is provided between the frame and the body, and a locking mechanism is provided on the frame to lock the position of the body when the body is moved up to a position and enters a working state.

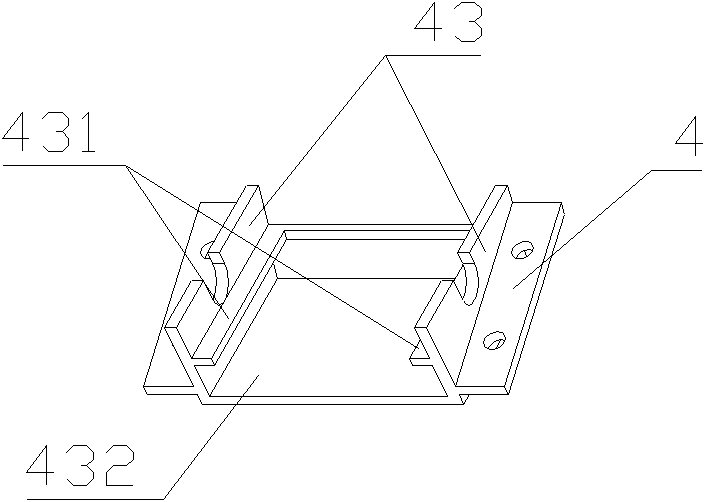

[0022] Described elevating mechanism comprises connecting plate 3 and torsion spring 31, and the lower end of connecting plate is transferred on the frame by positioning pin 32, and the upper end of connecting plate is transferred on the body, and one end of torsion spring is fixed on the frame, torsional The other end of the spring is fixed on the connecting plate, and when the connecting plate rotates as the body moves up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com