Method for recovering rare earth oxide from fluorescent powder and polishing powder waste

A rare earth oxide and polishing powder technology, which is applied in the field of rare earth resource recycling, can solve the problems of waste of valuable resources, emissions, and low acid dissolution rate of rare earth waste, and achieve the effect of reducing production costs and superior product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

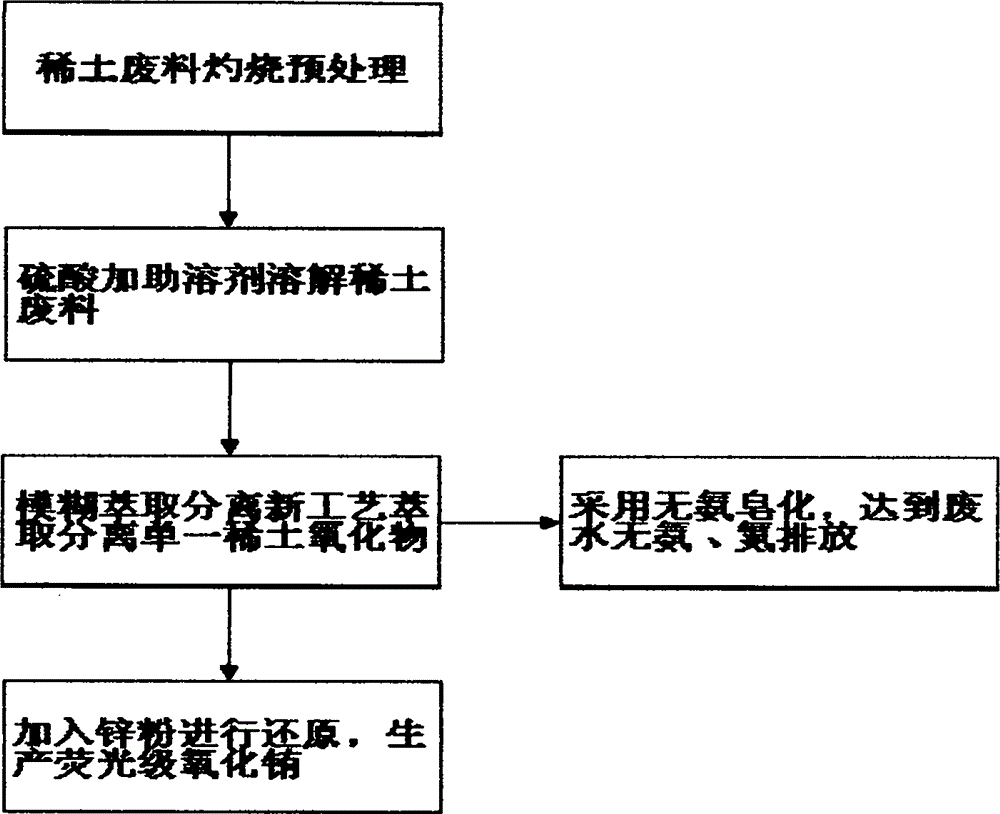

Method used

Image

Examples

Embodiment 1

[0031] Rare earth oxides were recovered from rare earth phosphor waste by the following steps:

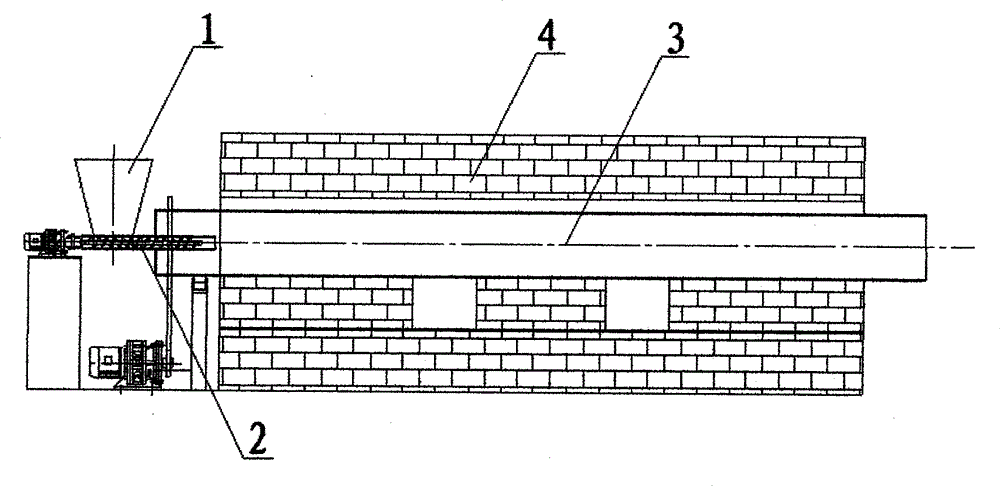

[0032] (1) Burn 405g of waste using a self-designed burning kiln.

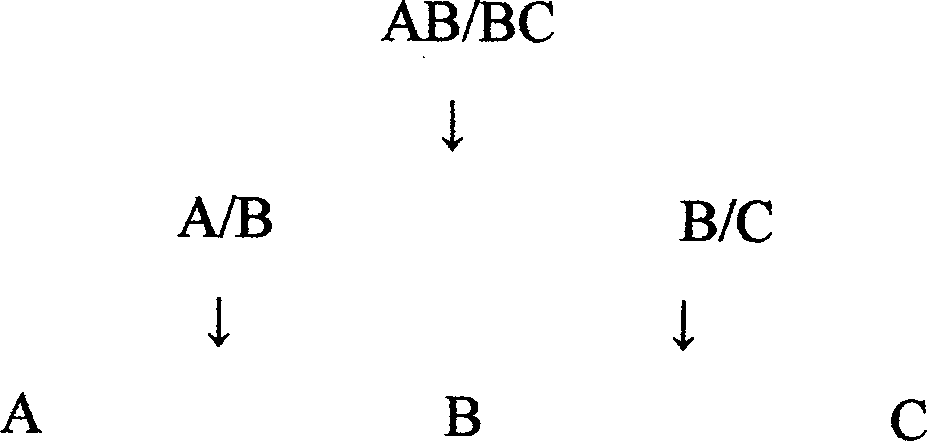

[0033] (2) The filter residue is returned to the dissolved material and continues to dissolve; the filtrate enters the multi-stage extraction tank for rare earth extraction and separation. h 2 SO 4 Add cosolvent to dissolve rare earth waste. Use hydrogen peroxide as cosolvent, glacial acetic acid to adjust acidity (sulfuric acid 87%, hydrogen peroxide 6%, glacial acetic acid 5%), by heating to 90-110 ℃, by the amount of rare earth metal in waste: acid solvent=1: 3, heating and stirring for 3 Hours, the rare earth decomposition rate in the waste material reaches 98.9%.

[0034] (3) Use rare earth-loaded organic as saponified organic, pure rare earth feed liquid as acid washing, and a new fuzzy extraction and separation process that combines back-acid / acid washing parallel flow technology with organic rare earth ...

Embodiment 2

[0038] Rare earth oxides were recovered from polishing powder waste by the following steps:

[0039] (1) Burn 362g of waste using a self-designed burning kiln.

[0040] (2) The filter residue is returned to the dissolved material and continues to dissolve; the filtrate enters the multi-stage extraction tank for rare earth extraction and separation. h 2 SO 4 Add cosolvent to dissolve rare earth waste. Use hydrogen peroxide as a cosolvent, glacial acetic acid to adjust the acidity (92% of sulfuric acid, 7% of hydrogen peroxide, 4% of glacial acetic acid), by heating to 90-110 ° C, according to the amount of rare earth metals in the waste: acid solvent=1: 3, heating and stirring for 3 Hours, make the rare earth decomposition rate in the waste material reach more than 99.2%.

[0041] (3) Use rare earth-loaded organic as saponified organic, pure rare earth feed liquid as acid washing, and a new fuzzy extraction and separation process that combines back-acid / acid washing paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com