Energy recovery system and method for air suspension

An energy recovery and air suspension technology, applied in suspension, elastic suspension, control devices, etc., can solve problems such as low energy recovery efficiency, inability to adjust height, and inability to recover energy, so as to improve efficiency and ensure ride comfort. , the effect of improving energy recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

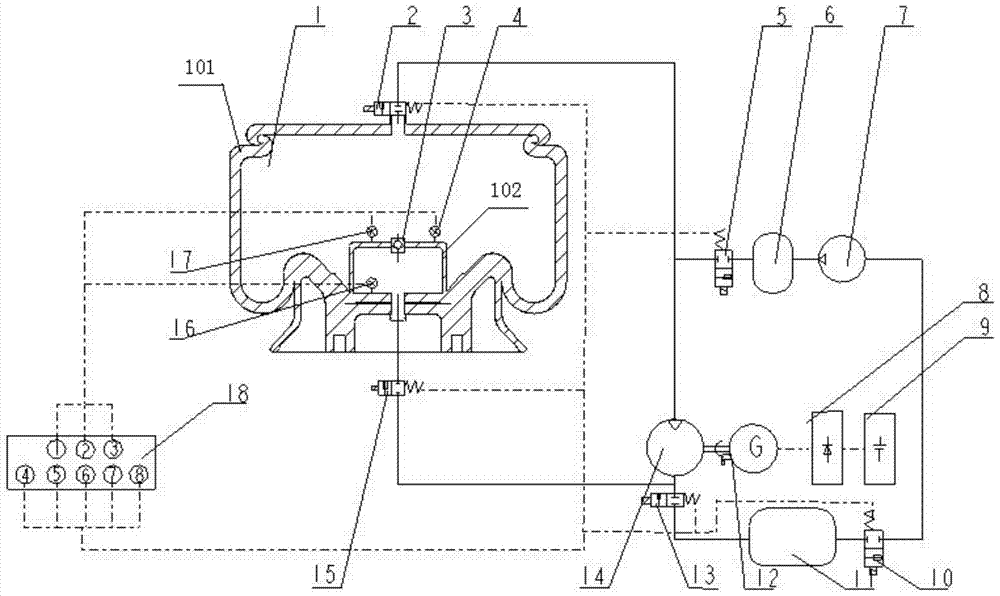

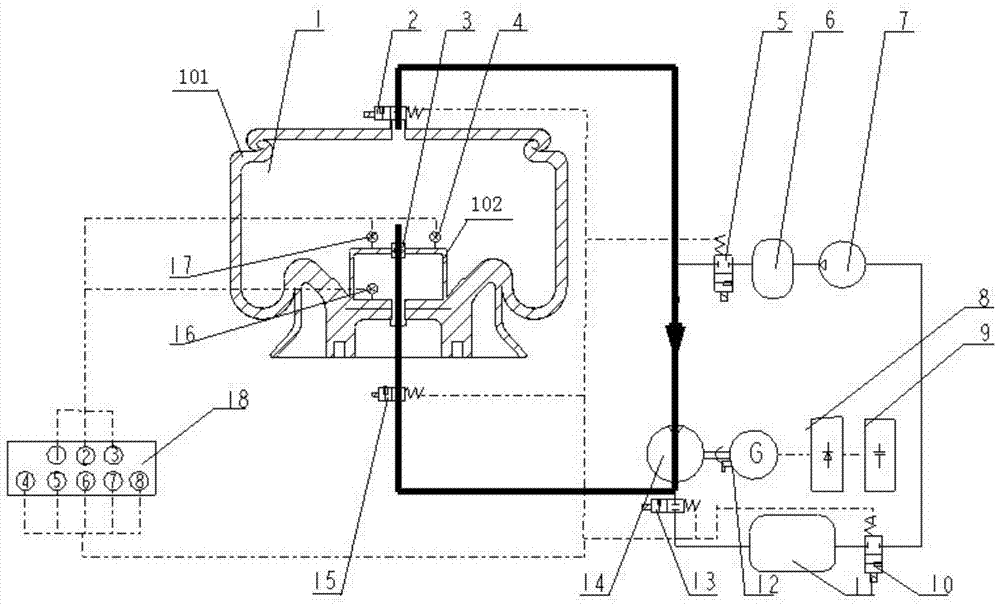

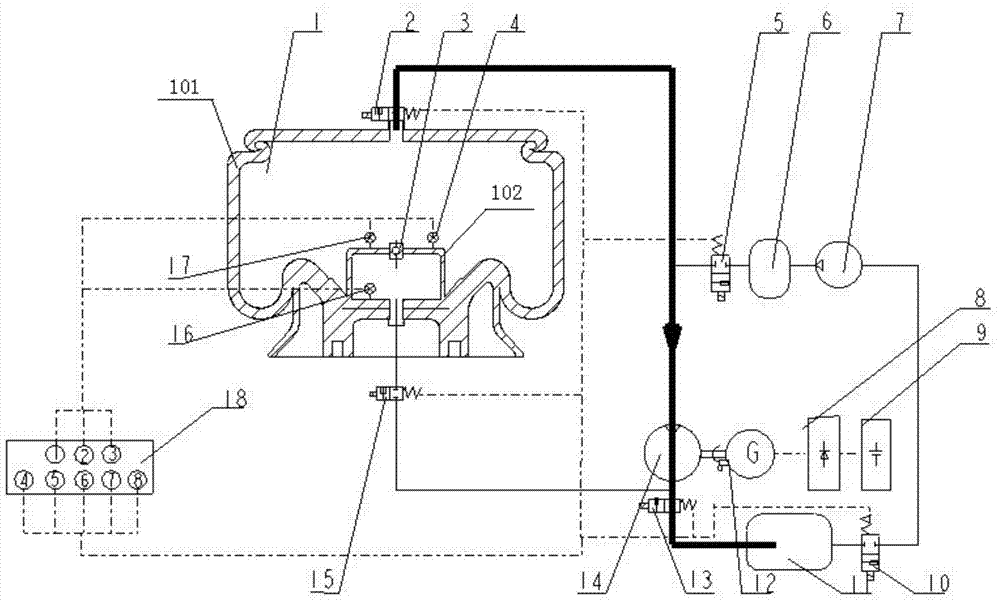

[0045] figure 1 Shown is an embodiment of the energy recovery system of the air suspension of the present invention, the energy recovery system of the air suspension includes an air spring shock absorber 1, a pneumatic actuator, a detection mechanism, a high-pressure storage tank 6, an air Compressor 7, low-pressure storage tank 11, air motor 14, power generation equipment and electronic control unit ECU18.

[0046] The pneumatic actuator includes a solenoid valve a2, a one-way valve 3, a solenoid valve b5, a solenoid valve c10, a solenoid valve d13 and a solenoid valve e15.

[0047] The pneumatic motor 14 is connected with the power generating equipment, and the power generating equipment includes a generator 12, a rectifier circuit 8 and a storage battery 9; the pneumatic motor 14 is connected with the generator 12, and the generator 12 passes through the rectifier The circuit 8 is electrically connected to the storage battery 9 .

[0048] The air spring shock absorber 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com