Manufacturing method of long-acting mosquito-expelling textile

A production method and fabric technology, applied in the direction of knitting, rayon production, animal repellent, etc., can solve the problems of inconvenient installation, inability to change and remove the isolation layer at will, and poor air permeability of the mosquito net structure, so as to prevent mosquito bites Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A manufacturing method of a long-acting mosquito repellent fabric of the present invention comprises the following steps:

[0017] a. One or more combinations of polyester fiber, high-density polyethylene and polypropylene are used as raw materials, and the raw materials are mixed with hygienic insecticides;

[0018] b. heating the mixture obtained in step a to 150-250°C and drawing it into monofilament or composite filament;

[0019] c. after the monofilament or composite filament is cooled to normal temperature, it is woven into a mesh fabric;

[0020] d. making the mesh fabric into a fabric.

[0021] The step a is specifically mixing 100 parts of polyester fiber with 1 to 30 parts of masterbatch, wherein the masterbatch is 1 to 30 parts of color masterbatch, 1 to 24 parts of antiaging agent, 1 to 26 parts of flame retardant, It is composed of 1-10 parts of hygienic insecticide and 1-10 parts of low-density polyethylene.

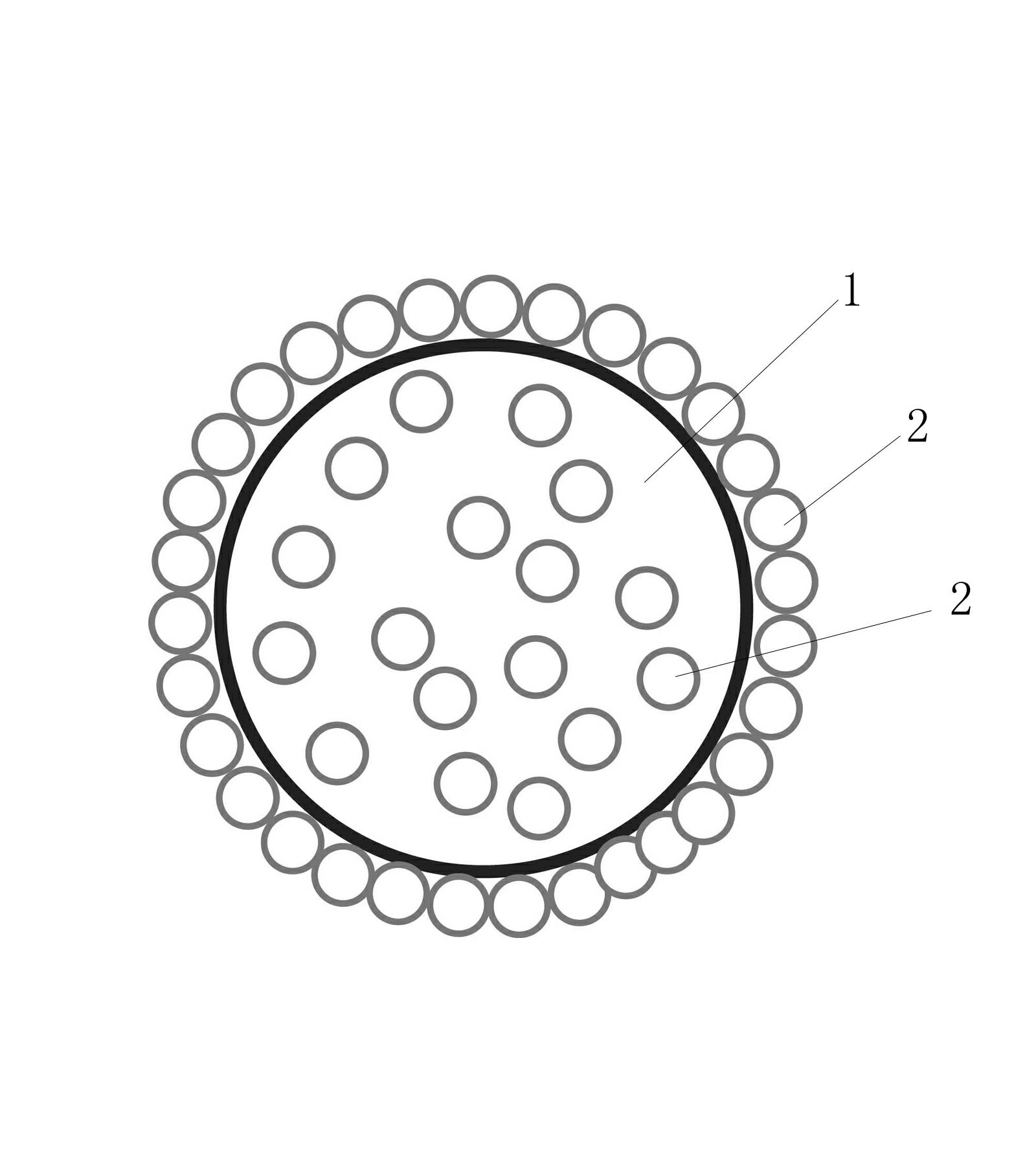

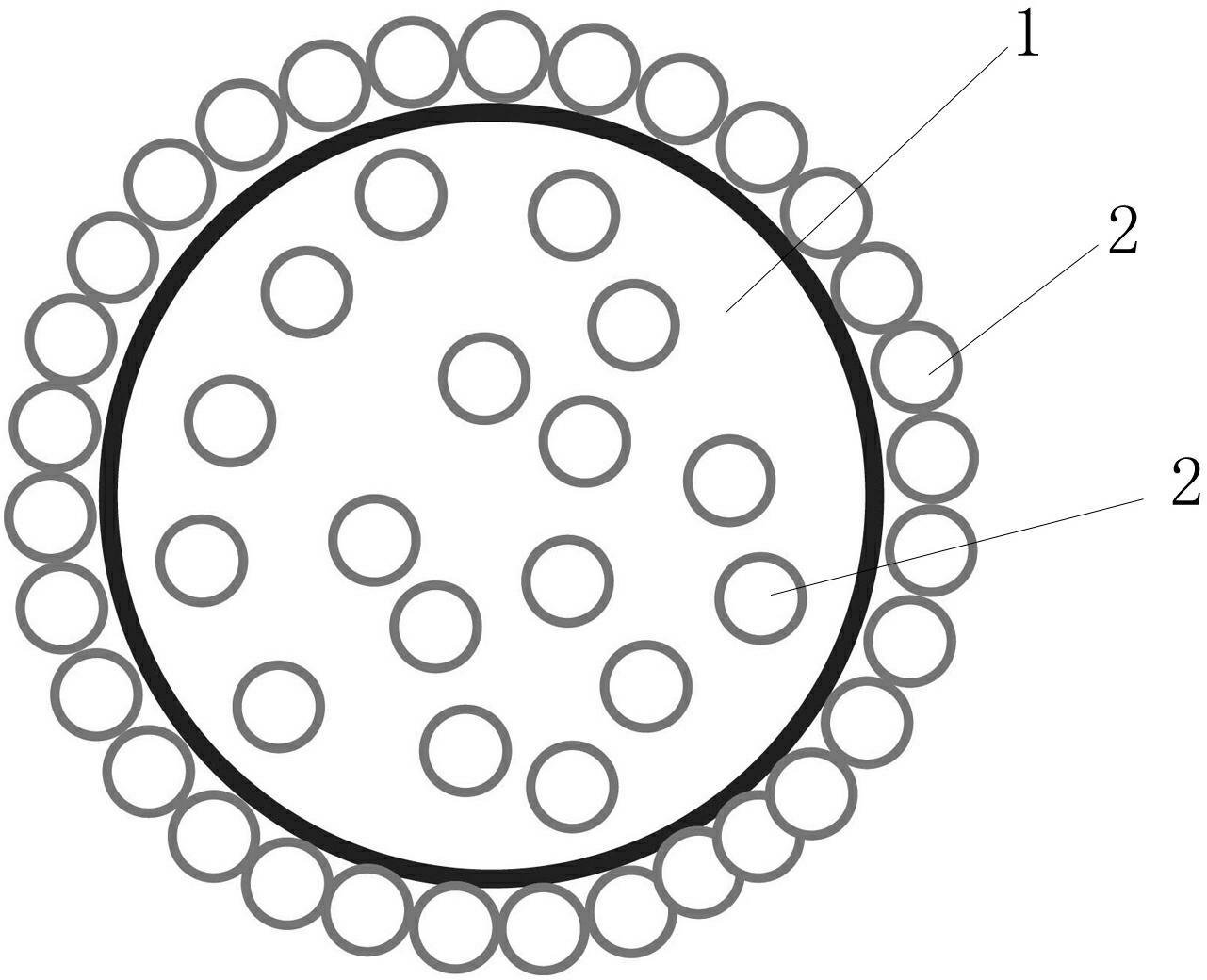

[0022] refer to figure 1 The inside and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com