Method for closing bottom of steel boxed cofferdam and gaps among river beds

A steel-jacketed box and cofferdam technology, applied in caisson, construction, infrastructure engineering and other directions, can solve problems such as heavy workload, difficulty, and time-consuming, and achieve strong adaptability to water flow, fast blocking speed, and blocking good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with embodiment.

[0026] A method for closing the gap between the bottom of the steel box cofferdam and the riverbed:

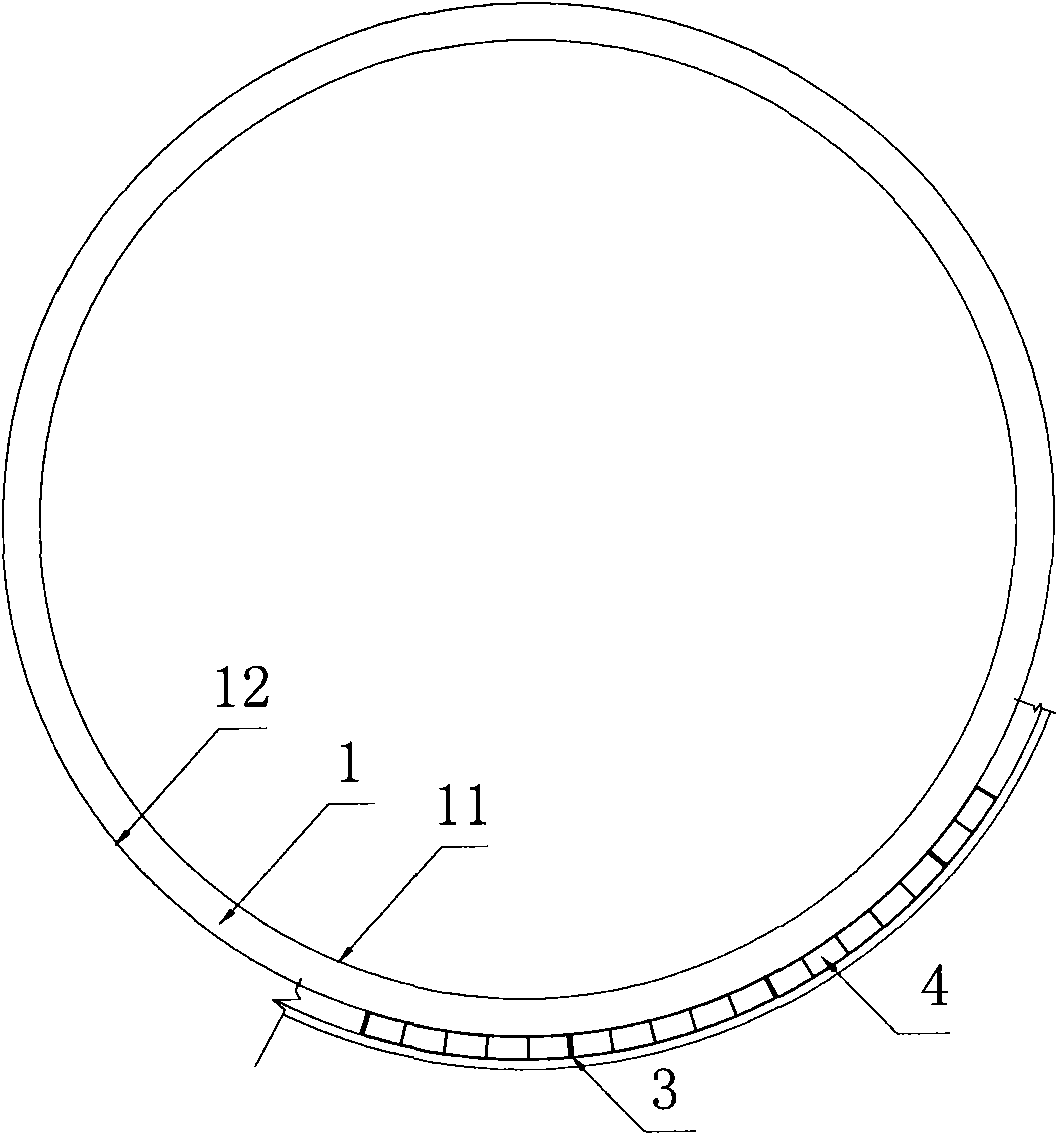

[0027] a. Assembling a steel box cofferdam 1 on the shore, the cofferdam 1 includes a cofferdam outer wall 12 and a cofferdam inner wall 12;

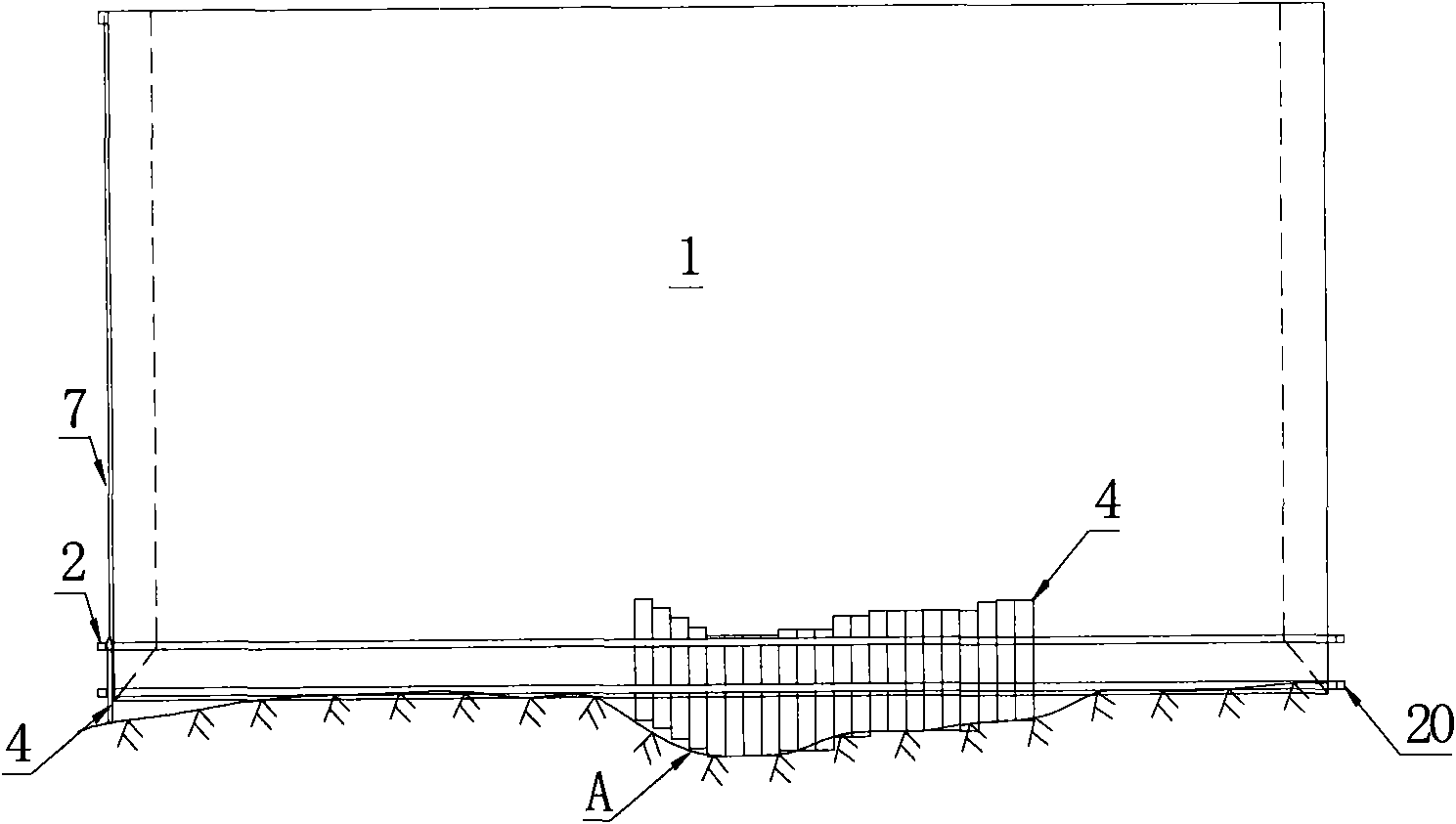

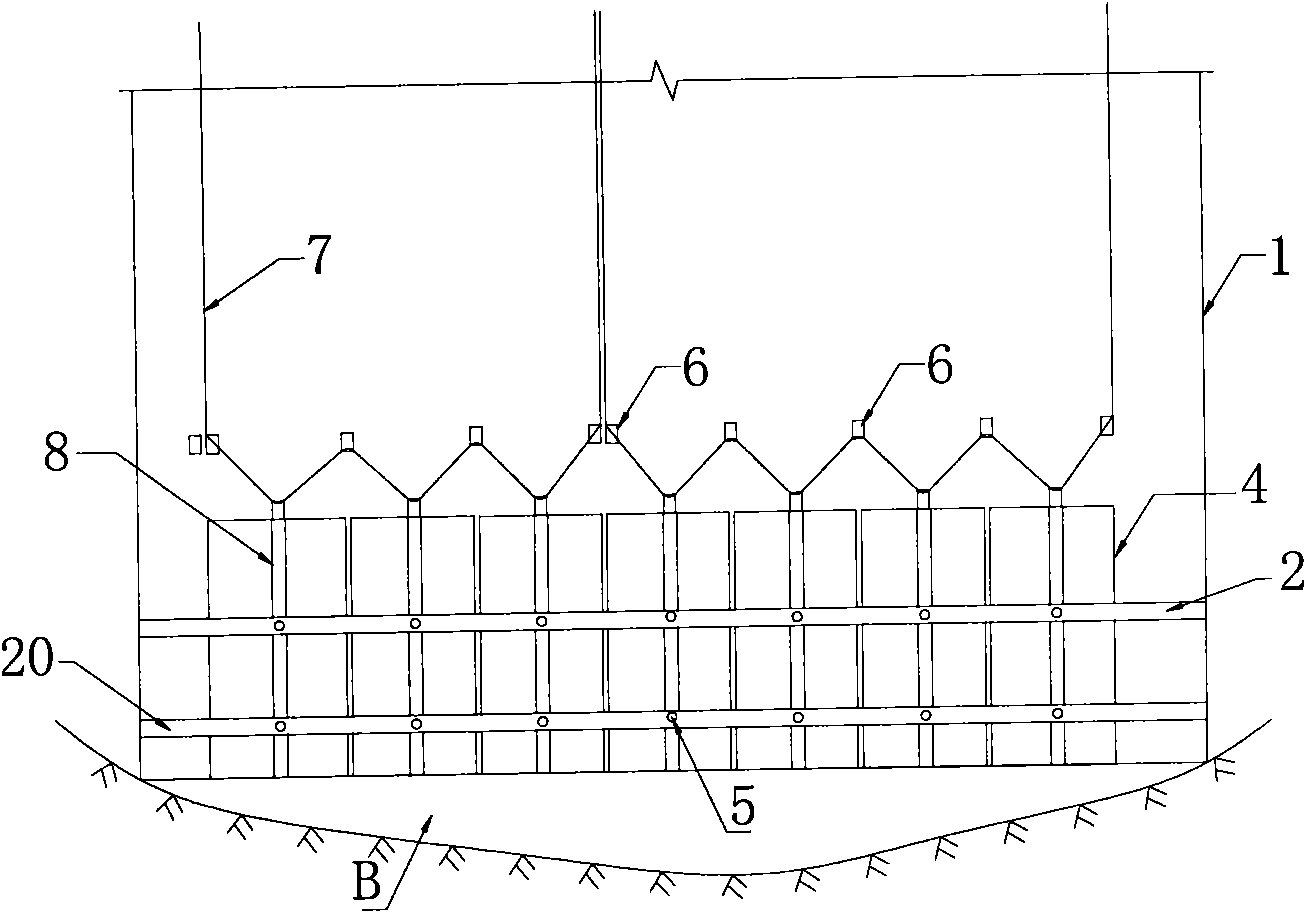

[0028] b. Install the retaining beam in the area that needs to be closed. The retaining beam includes the upper retaining beam 2 and the lower retaining beam 20. The upper retaining beam 2 and the lower retaining beam 20 are made of channel steel or square pipes of the same specification. The spacing is 0.8 to 1.2 meters, and the lower beam 20 is higher than the bottom of the cofferdam and 0.2 to 0.4 meters away from the bottom of the cofferdam. And there is a certain distance between the upper retaining beam 2 and the lower retaining beam 20 and the outer wall 12 of the cofferdam to form a storage space for the movable board 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com