Liquid crystal display device panel and manufacturing method thereof

A technology of liquid crystal display device and manufacturing method, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problem that the thickness of the cell is difficult to select the transmittance, etc., achieve good transmittance of the liquid crystal cell, optimize the average optical retardation value, and realize The effect of wide viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

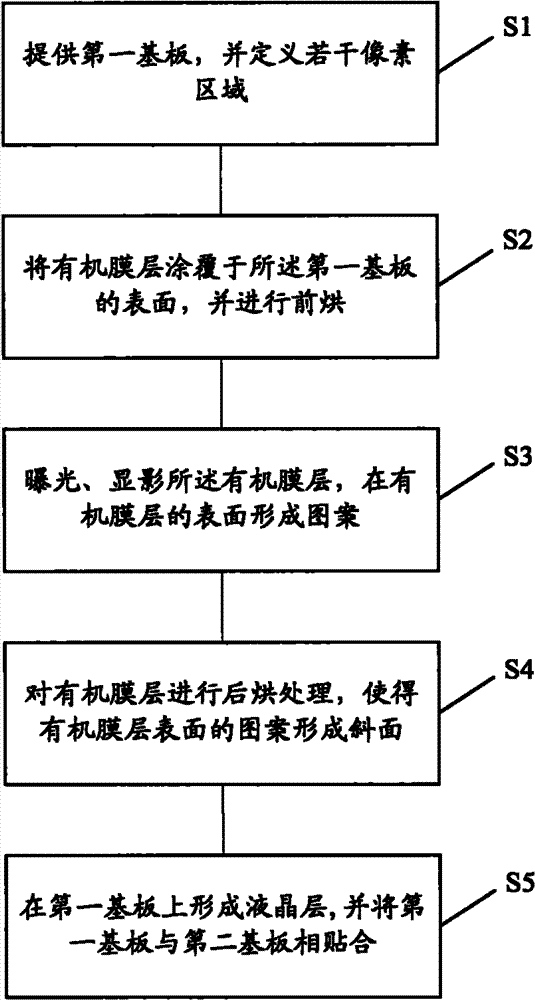

[0034] The specific embodiments of the present invention will be further introduced in conjunction with the accompanying drawings.

[0035] The smallest display unit of a liquid crystal display is a pixel. Therefore, the panel of the liquid crystal display device includes a pixel array, so the panel of the liquid crystal display device can be divided into several pixel regions, and the pixel regions are separated by data lines and scan lines.

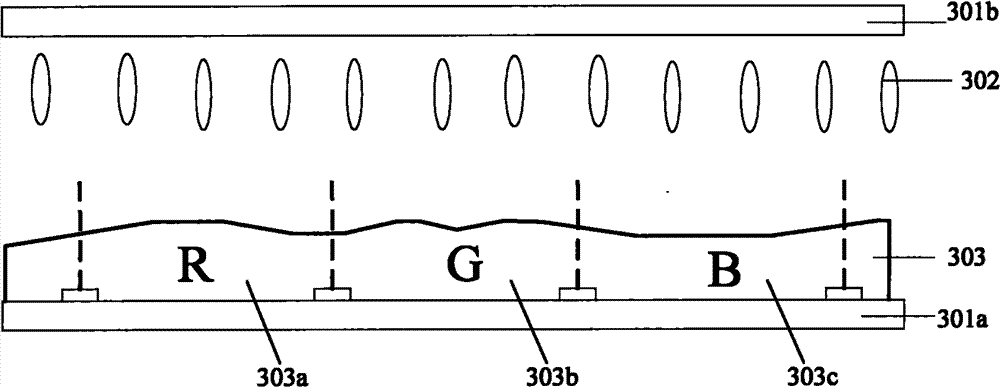

[0036] Such as figure 1 Shown is a schematic structural view of a single pixel region of the liquid crystal display panel of the present invention, and the liquid crystal display panel includes:

[0037] The first substrate 301a; the second substrate 301b; the organic film layer 303, located on the side of the first substrate 301a facing the second substrate 301b;

[0038] The liquid crystal layer 302 is located between the first substrate 301a and the second substrate 301b;

[0039] A single pixel can also be divided into multiple su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com