Condensation dryer with a heat pump and recognition of an impermissible operating state and method for the operation thereof

An operating state, dryer technology, used in household dryers, household appliances, textiles and papermaking, etc., can solve problems such as inaccurate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

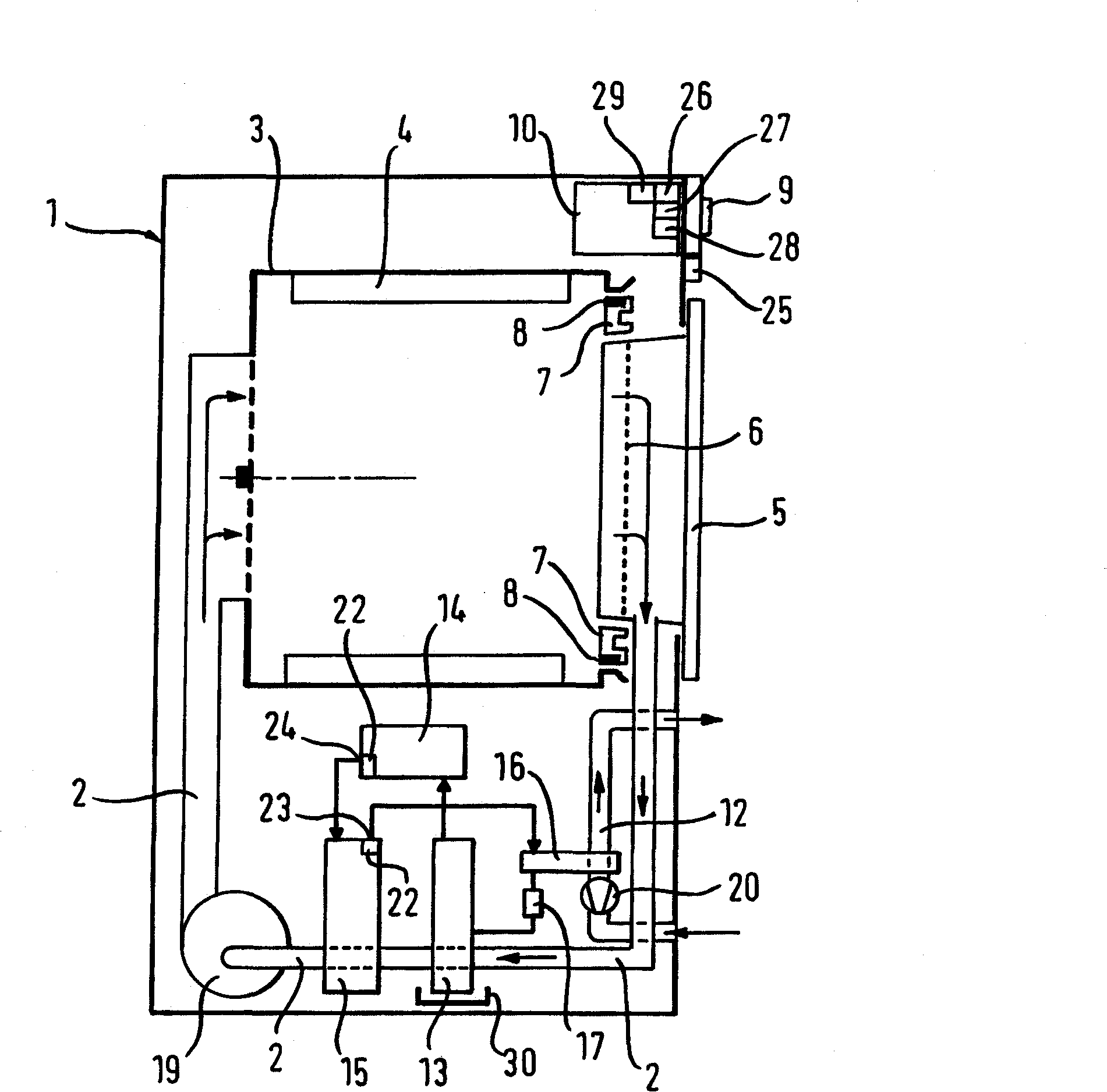

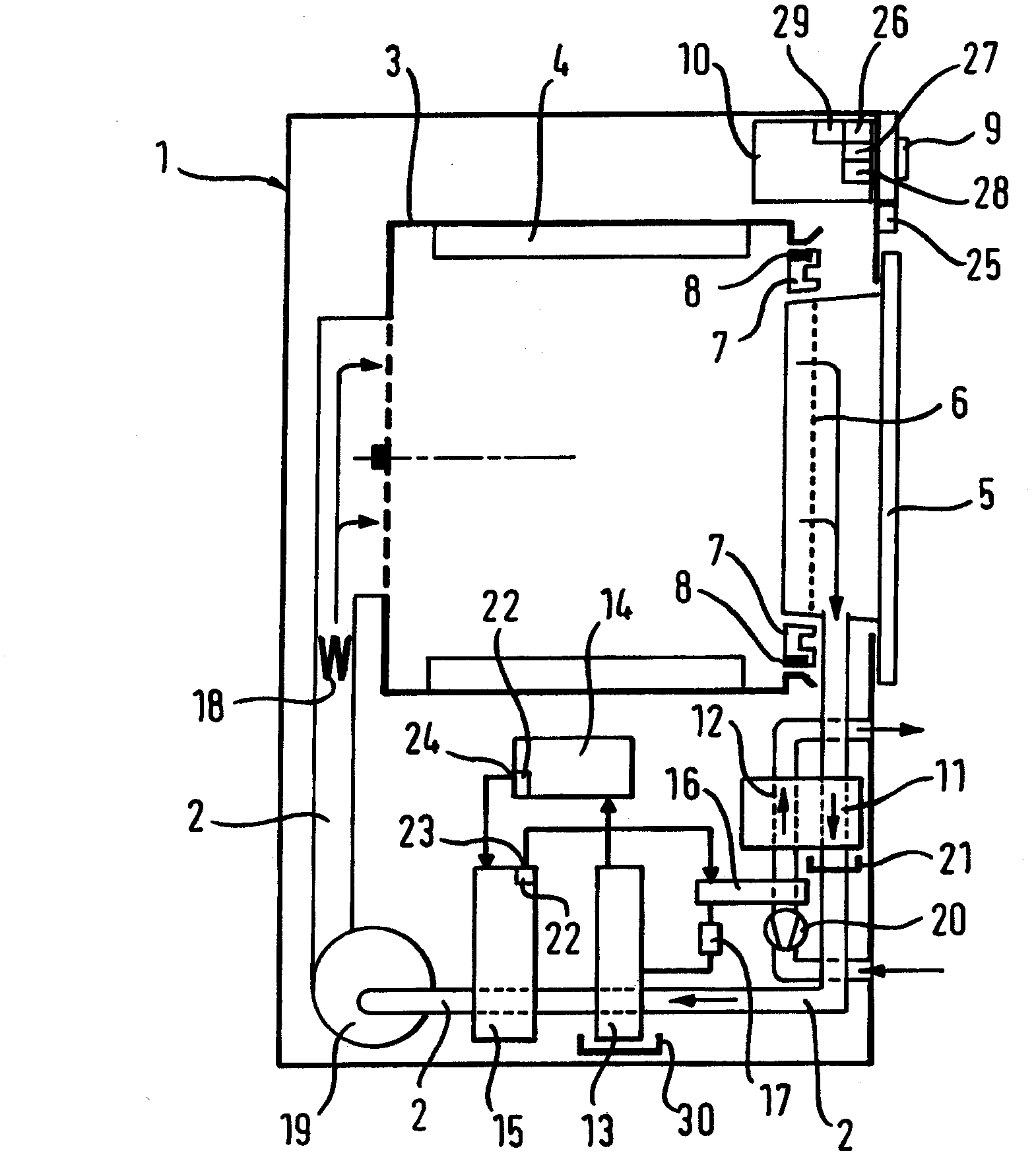

[0051] figure 1 A condensation dryer according to a first embodiment variant (hereinafter simply referred to as "dryer") is shown in vertical section, wherein the process air is only heated via the condenser of the heat pump.

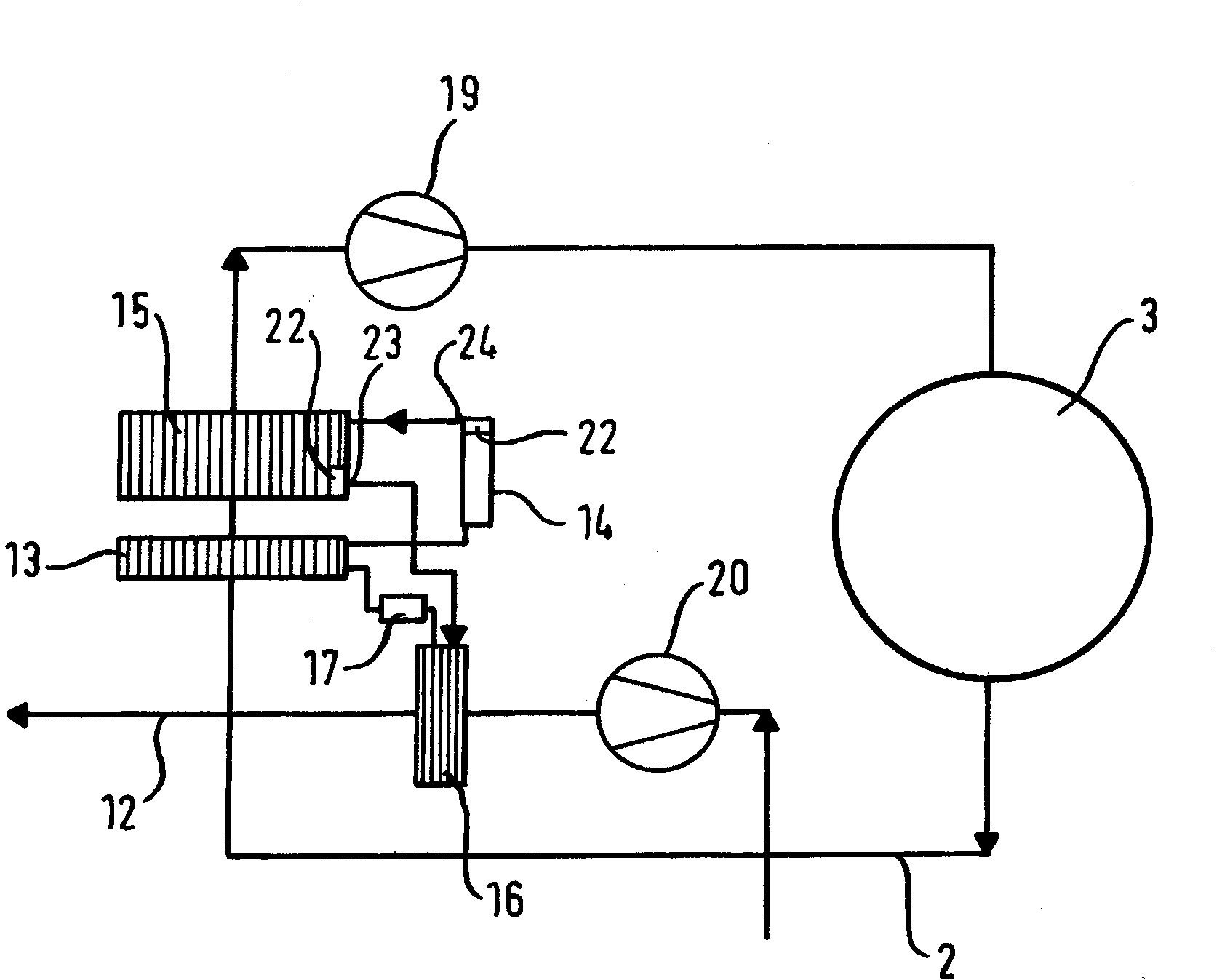

[0052] figure 1The dryer 1 shown in has a drum rotatable about a horizontal axis as a drying chamber 3 in which a lifting structure 4 for moving laundry while the drum is rotating is fixed. The process air is conveyed by means of a first fan 19 through the drum 3 and the heat pumps 13 , 14 , 15 , 17 in a closed circuit in the air channel 2 (process air circuit 2 ). The process air heated in the condenser 15 of the heat pumps 13 , 14 , 15 , 17 is cooled and absorbs moisture after passing through the drum 3 and is heated again by means of the condenser 15 after the moisture contained in the process air has been condensed. The heated air is conducted here from the rear side, ie through the perforated bottom of the drum, from the side of the drum 3 oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com