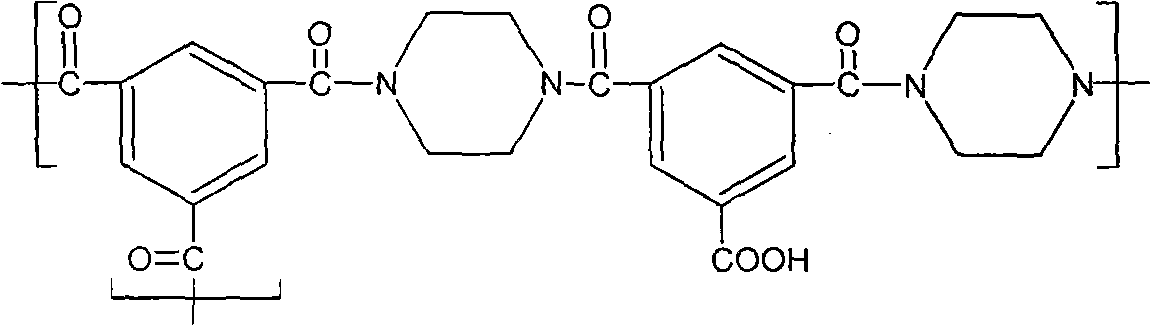

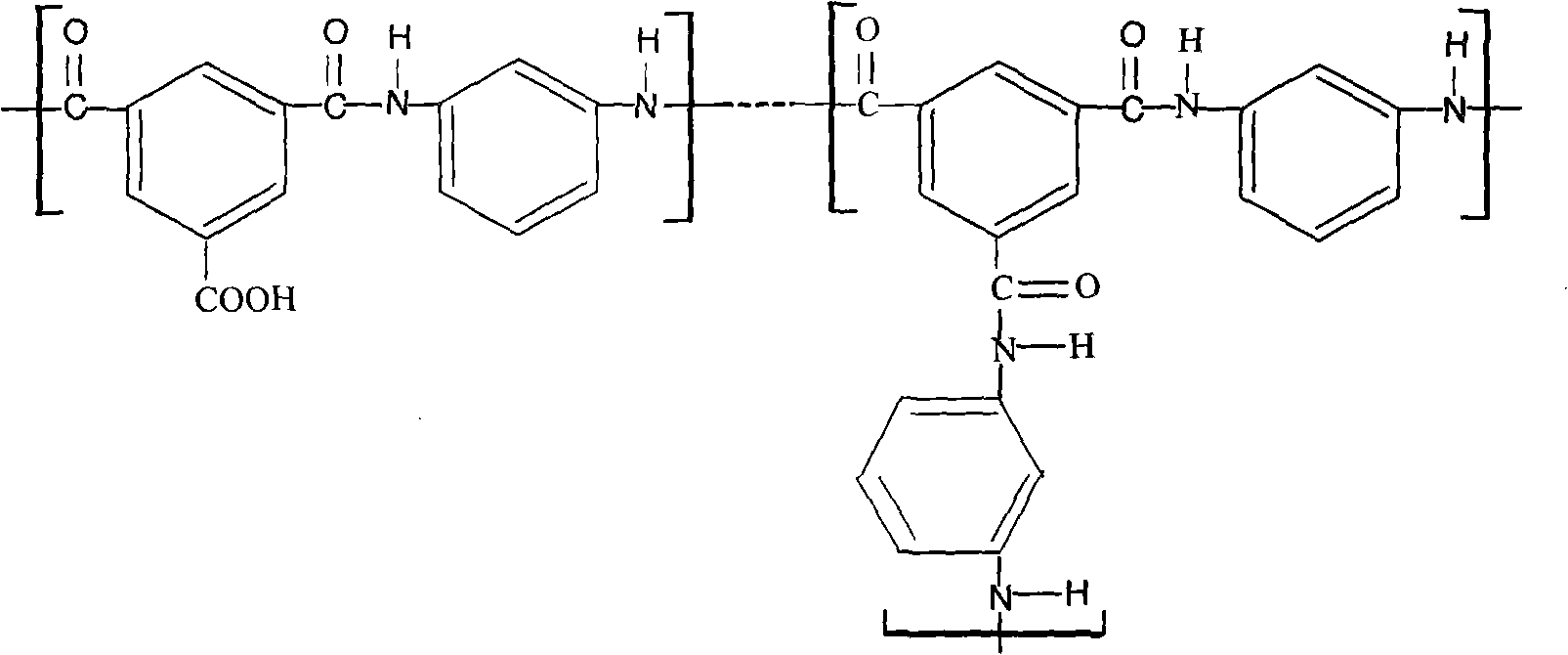

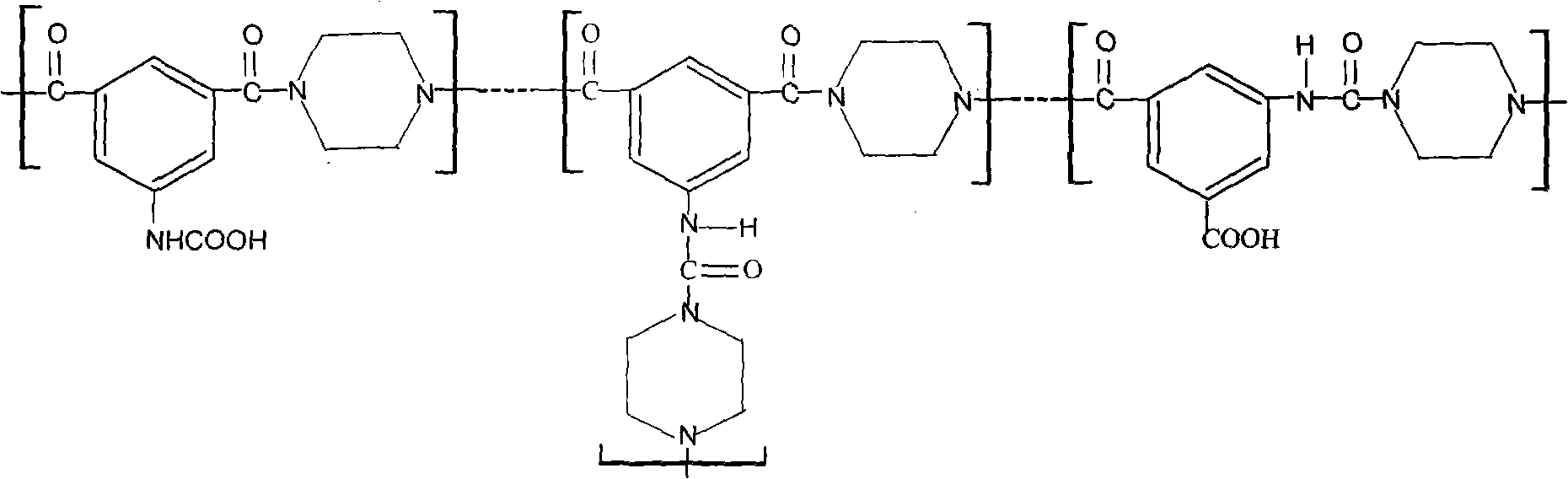

Method for preparing acid-proof polysulfonamide nanofiltration composite film

The technology of sodium polysulfonamide and polysulfonamide is applied in the field of acid-resistant polysulfonamide nanofiltration composite membrane and its preparation, which can solve the problems of restricting the application of nanofiltration composite membrane, and achieve the effects of superior acid resistance and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention is described in detail below:

[0028] The following examples give descriptions of acid-resistant polysulfonamide nanofiltration composite membranes and their separation properties. However, these examples are provided only by way of illustration and not limitation of the present invention.

[0029] Preparation of porous support membrane: 13.5% of Udel PS3500 LCD polysulfone, 0.2% of water and 0.1% of surfactant were dissolved in N, N-dimethylacetamide, scraped on the polypropylene non-woven fabric, and then Immerse the gel in water, and remove the solvent to obtain a supported membrane with a molecular weight cut-off (MWCO) of about 80,000; the surfactant therein includes at least alkylphenol polyoxyethyl ester phosphate, or sodium dodecylsulfonate, or alkane One of the base phenol polyoxyethyl ester phosphates.

[0030] Preparation of nanofiltration composite membrane: immerse the wet polysulfone support membrane in the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com