Section steel concrete column-steel girder node

A concrete column and concrete technology, applied in the direction of building and building structure, can solve the problems of difficult to guarantee the quality of concrete in the node area, insufficient seismic performance of the node core area, low restraint effect in the node core area, etc., so as to improve the pouring quality and improve the Constraint effect, the effect of strengthening the restraint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

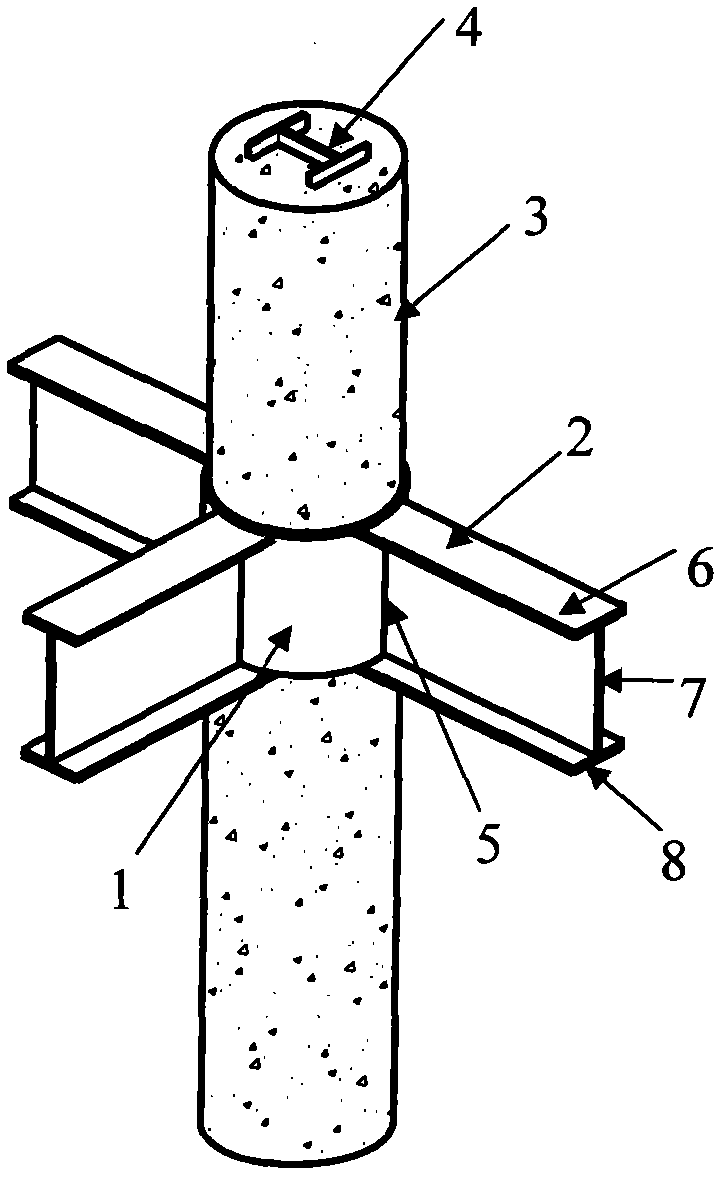

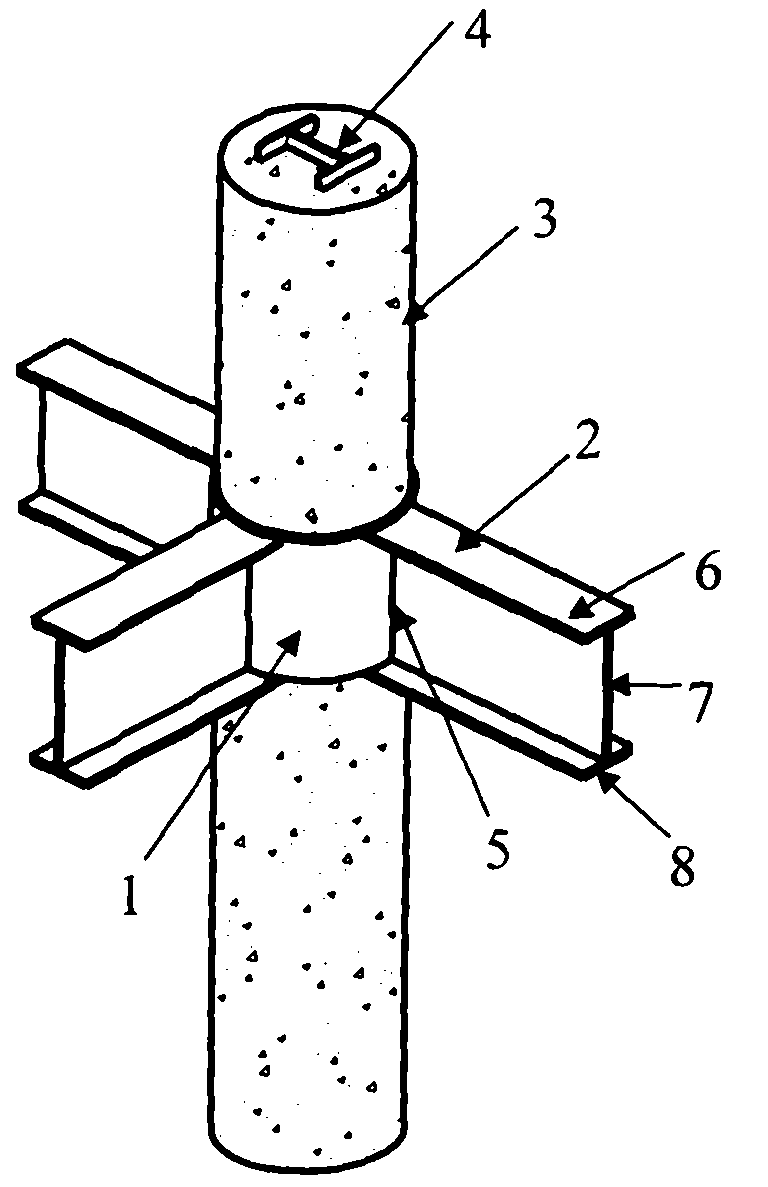

[0016] figure 1 It is the structural connection node between the circular steel pipe 1 of the present invention and the circular concrete column 3 with the steel beam 4 inside the column and the steel beam 2. Its specific structure is: the circular steel pipe 1 is partly located at the periphery of the circular concrete column 3 in the node area, The steel pipe 1 is connected to the web 7 of the horizontal steel beam 2 in the node area, and the steel pipe is located between the upper flange 6 and the lower flange 8 of the steel beam, that is, the height of the steel pipe 1 is the same as that of the steel beam web 7, and the steel pipe 1 is on the steel beam web The 7 places are disconnected and welded with the web 5 on both sides of the steel beam web 7 .

Embodiment 2

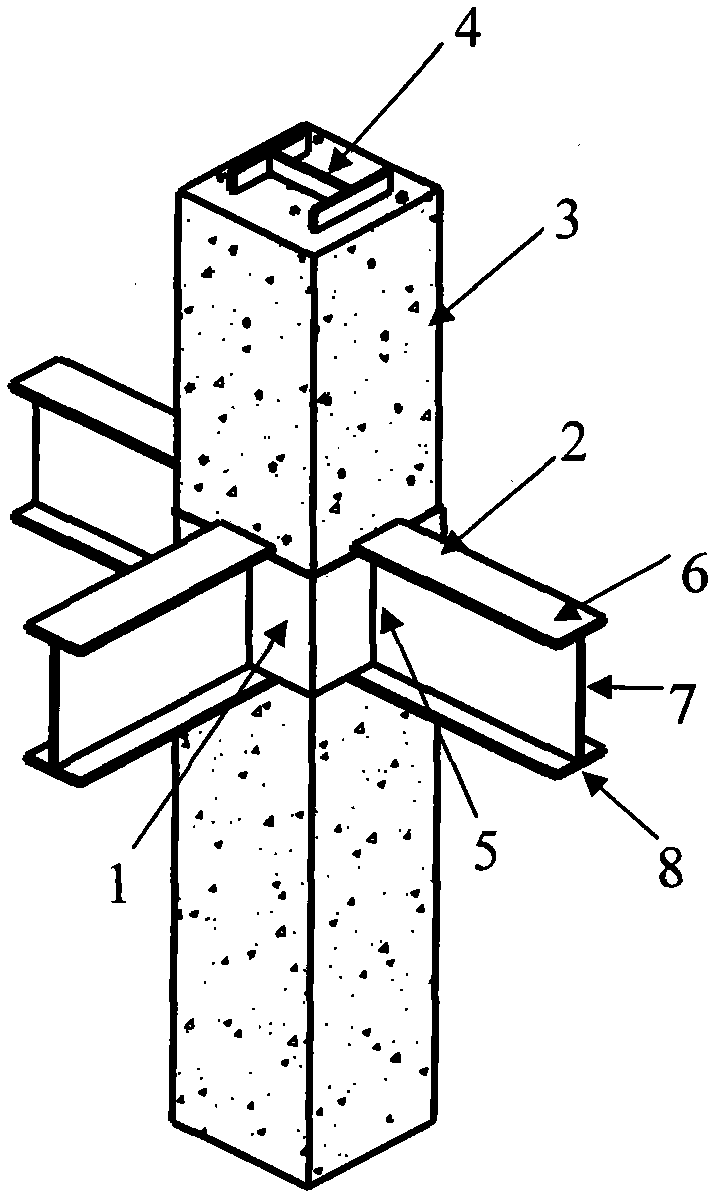

[0018] figure 2 It is the structural connection node between the rectangular steel pipe 1 of the present invention and the rectangular concrete column 3 with the steel beam 4 inside the column and the steel beam 2. The connection structure of the horizontal steel beams in the district is the same as that in Embodiment 1.

[0019] When the steel pipe in the node area of the present invention is a rectangular or circular steel pipe, it can be divided into finished steel pipes, or formed by cold bending or welding of steel plates;

[0020] The steel girder in the node area of the present invention can be welded or rolled I-beam or H-beam;

[0021] The profiled steel in the concrete column in the node area of the present invention can adopt welded or rolled profiled steel, and the section of the profiled steel can be H-shaped steel, cross-shaped steel or T-shaped steel;

[0022] The material used for the steel pipe 1, the steel beam 3, and the steel section inside the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com