Adjustable installing piece of lamp in factory

An adjustable and mounting technology, which is applied to the parts of lighting devices, lighting devices, light source fixing, etc., can solve the problems of heavy workload and low efficiency, and achieve the effects of improving efficiency, simple assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate the understanding of those skilled in the art, the invention will be further described below in conjunction with the accompanying drawings.

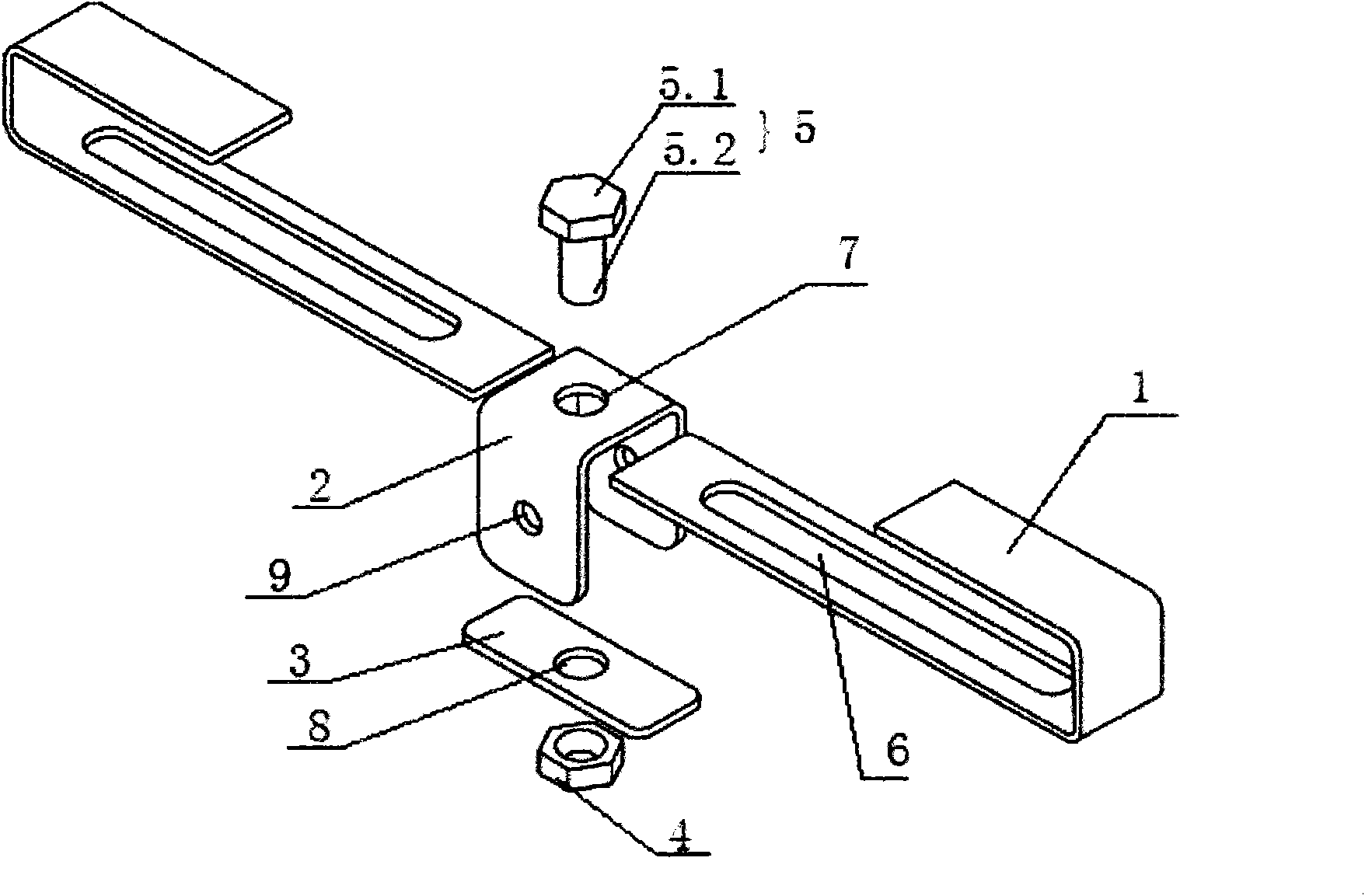

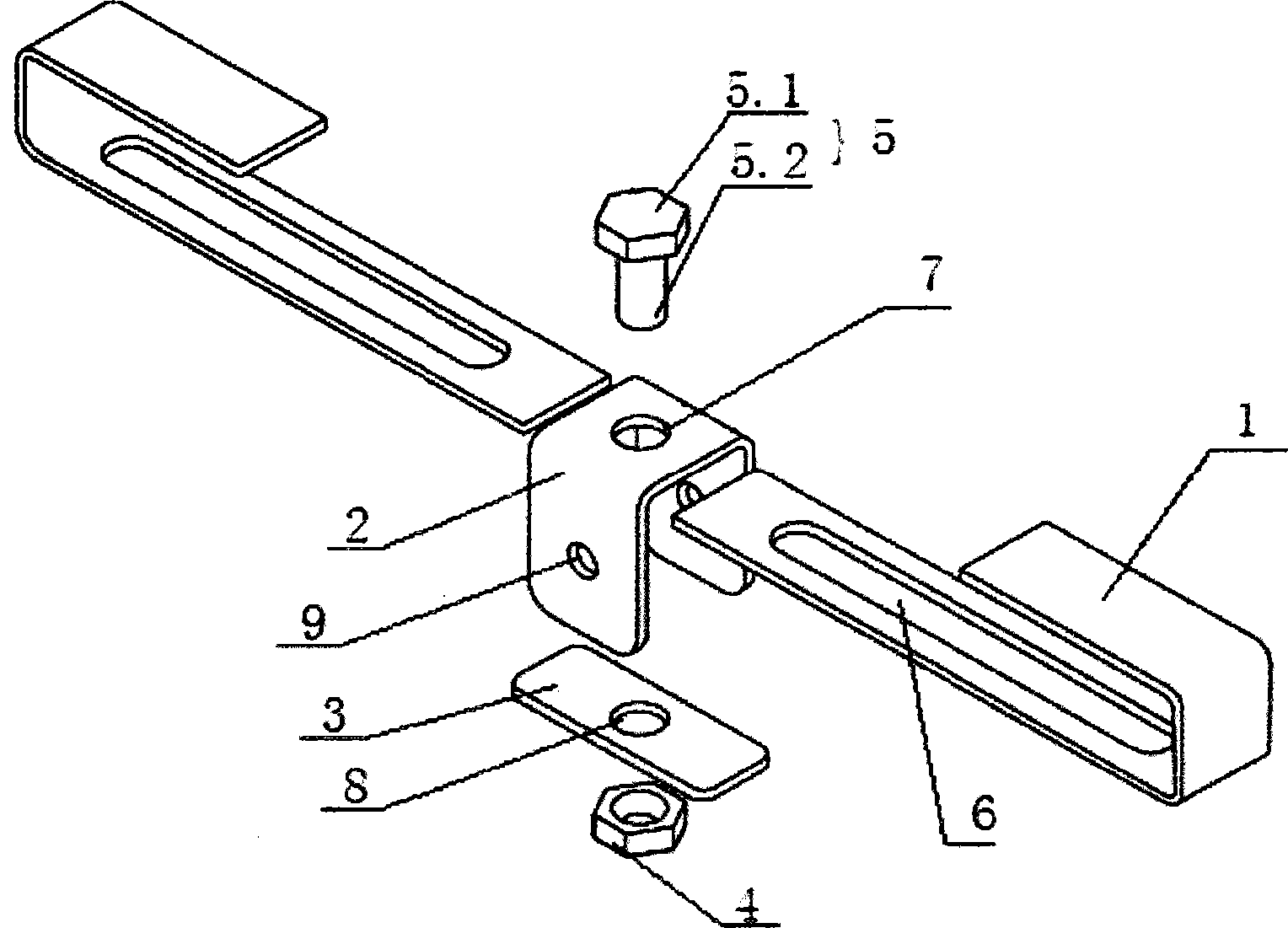

[0015] figure 1 Among them, the adjustable factory lamp mounting part of the present invention is composed of a set of I-shaped steel clips 1, inverted U-shaped lamp hangers 2, gaskets 3, nuts 4, and bolts 5 integrating screw rod 5.2 and nut 5.1. The bottom surface of the word steel clip 1 is provided with a chute 6, and the gasket 3 is provided with a round hole 8. The top plane of the inverted U-shaped lamp hanger 2 is provided with a round hole 7 .

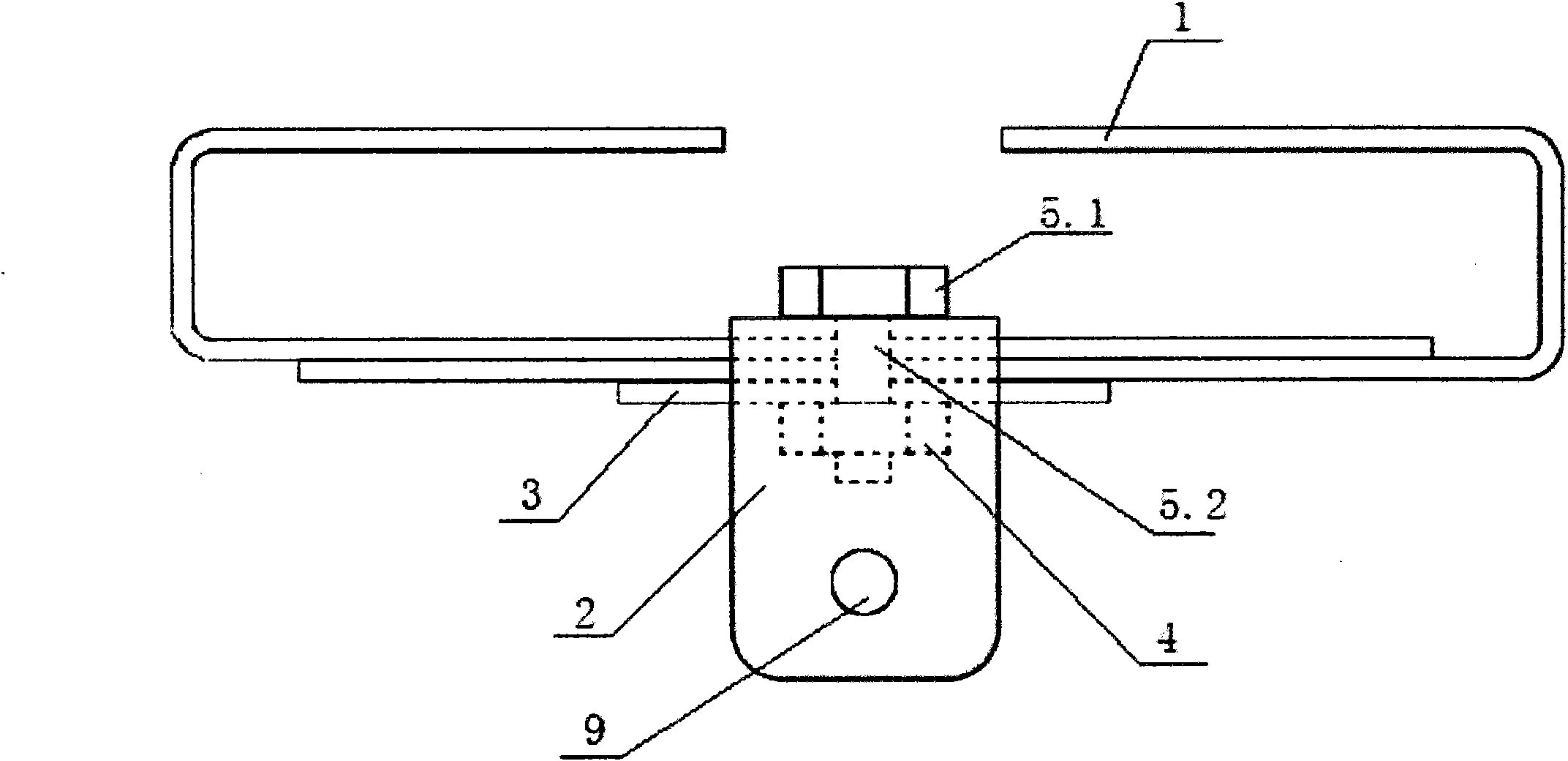

[0016] Such as figure 2 As shown, the screw rod 5.2 of the bolt 5 passes through the round hole 7 on the top plane of the inverted U-shaped lamp hanger, the chute 6, the round hole 8 of the gasket in turn, and then locks with the nut 4.

[0017] In order to facilitate installation, the width of the chute 6 on the bottom surface of the I-shaped steel clip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com