Method for judging pollution of dust sensor, wiping system and cleaning robot thereof

A dust sensor, dust technology, applied in robot cleaning machines, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of sticking dust and weak infrared signals, and achieve the effect of accurate judgment and maintaining sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings and taking an intelligent cleaning robot as an example.

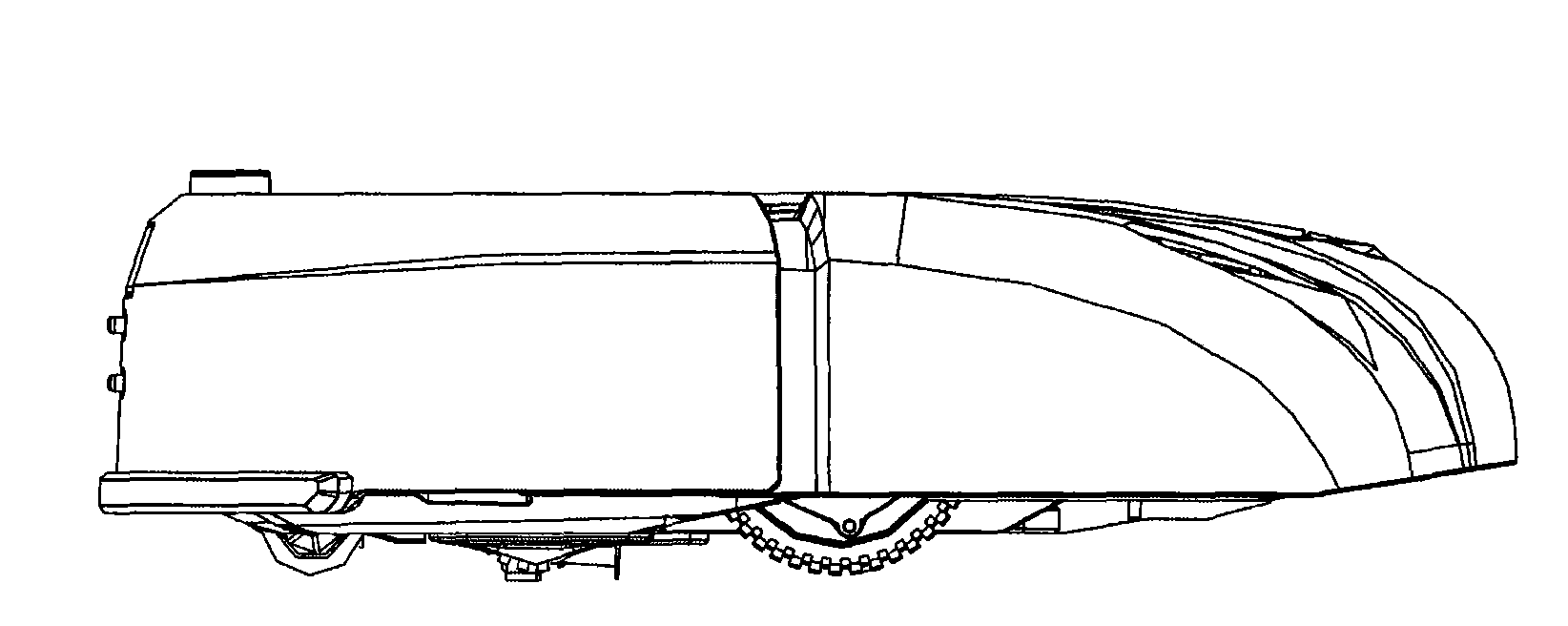

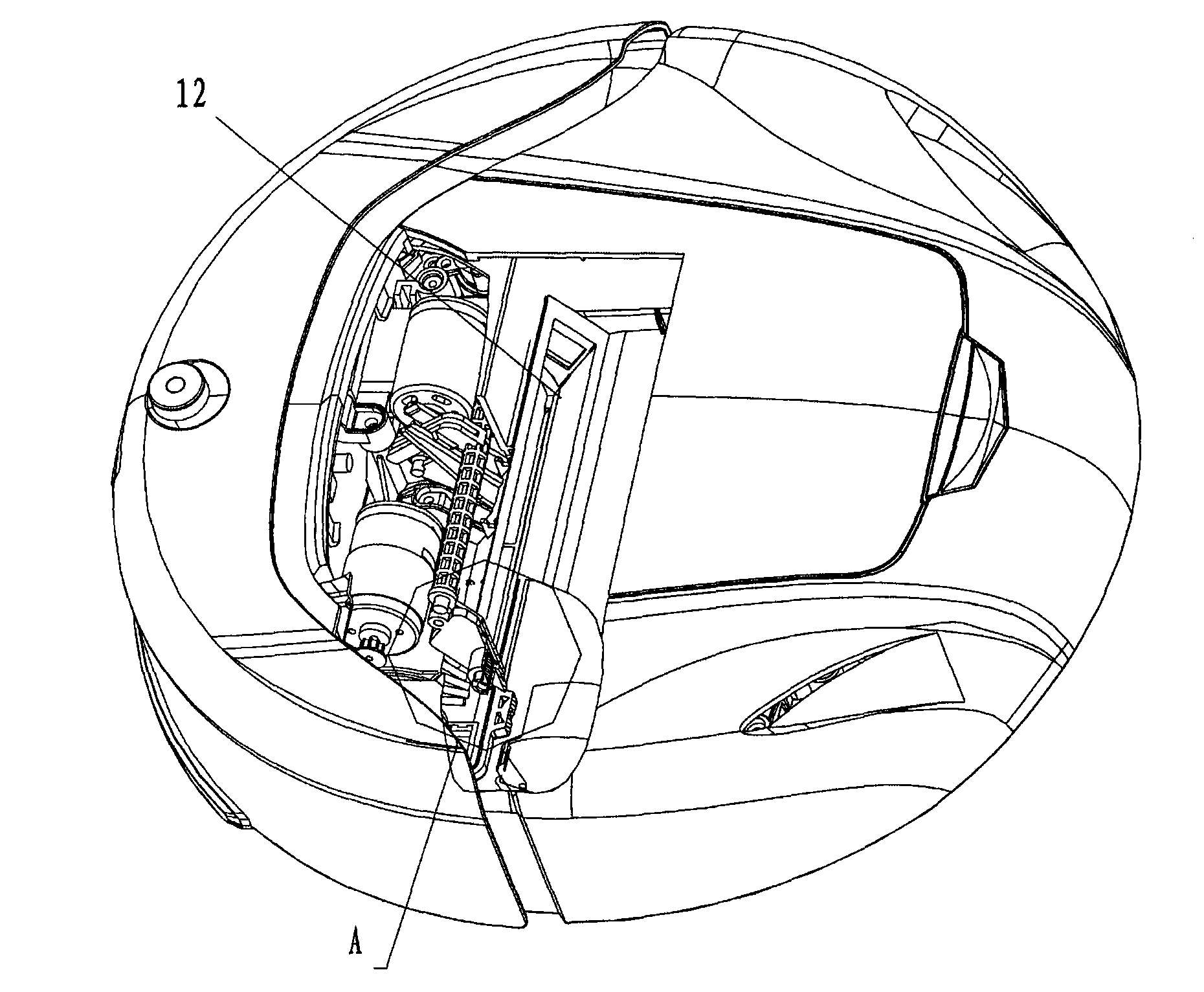

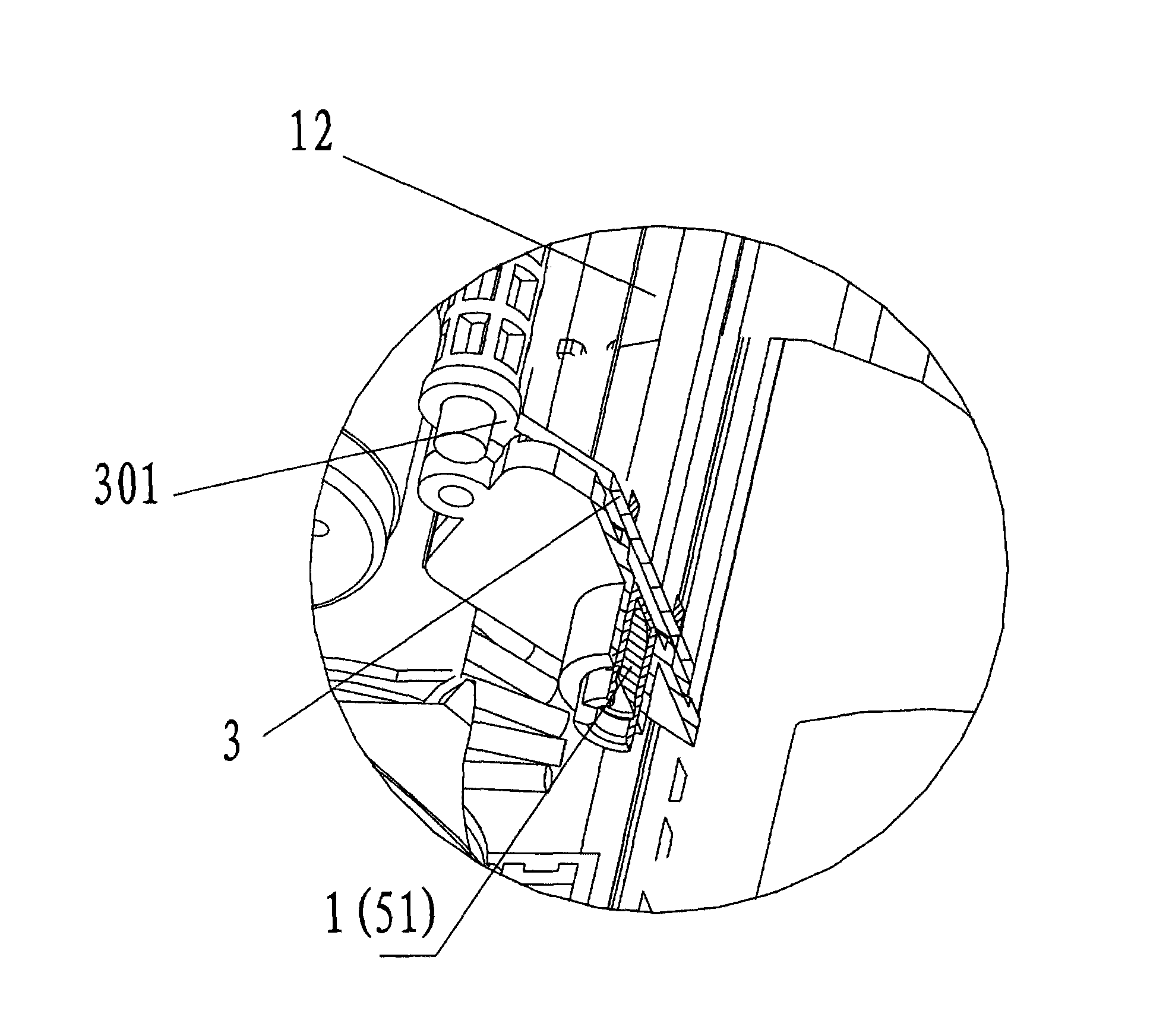

[0034] figure 1 Schematic diagram of the appearance of the intelligent cleaning robot. figure 2 It is a schematic diagram of the structure of the intelligent cleaning robot. image 3 for figure 2 Partial enlargement of part A in the middle. Figure 4 It is the composition block diagram of the dust sensor self-induction wiping system of the present invention. combine image 3 and Figure 4 As shown, the dust sensor self-induction wiping system of the present invention includes: a sensor unit 101, which has a dust sensor 1 composed of a pair of emitting and receiving optical signal elements, which is used to detect the amount of dust entering the dust channel 12; a wiping mechanism 301, which uses to wipe the dust sensor light-transmitting plate; and the control unit 201, which recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com