Vehicular carrying and working system special for bypass live working device

A technology of live work and work system, applied in the direction of cable laying equipment, etc., can solve the problems that affect the rapid popularization and application of bypass live work method, long work preparation time, high labor intensity of personnel, etc., so that the possibility of equipment damage is small, The effect of low labor intensity and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is further described

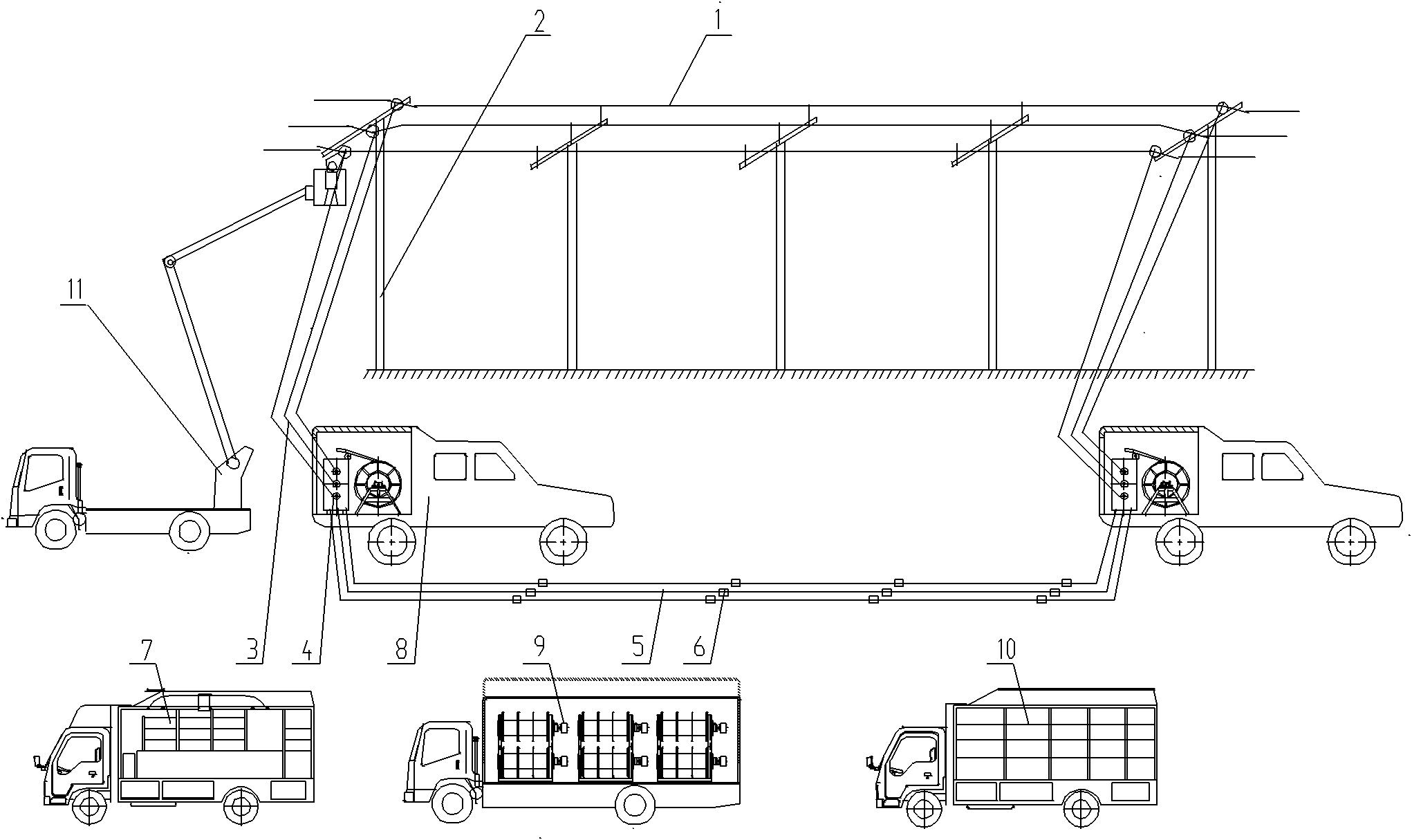

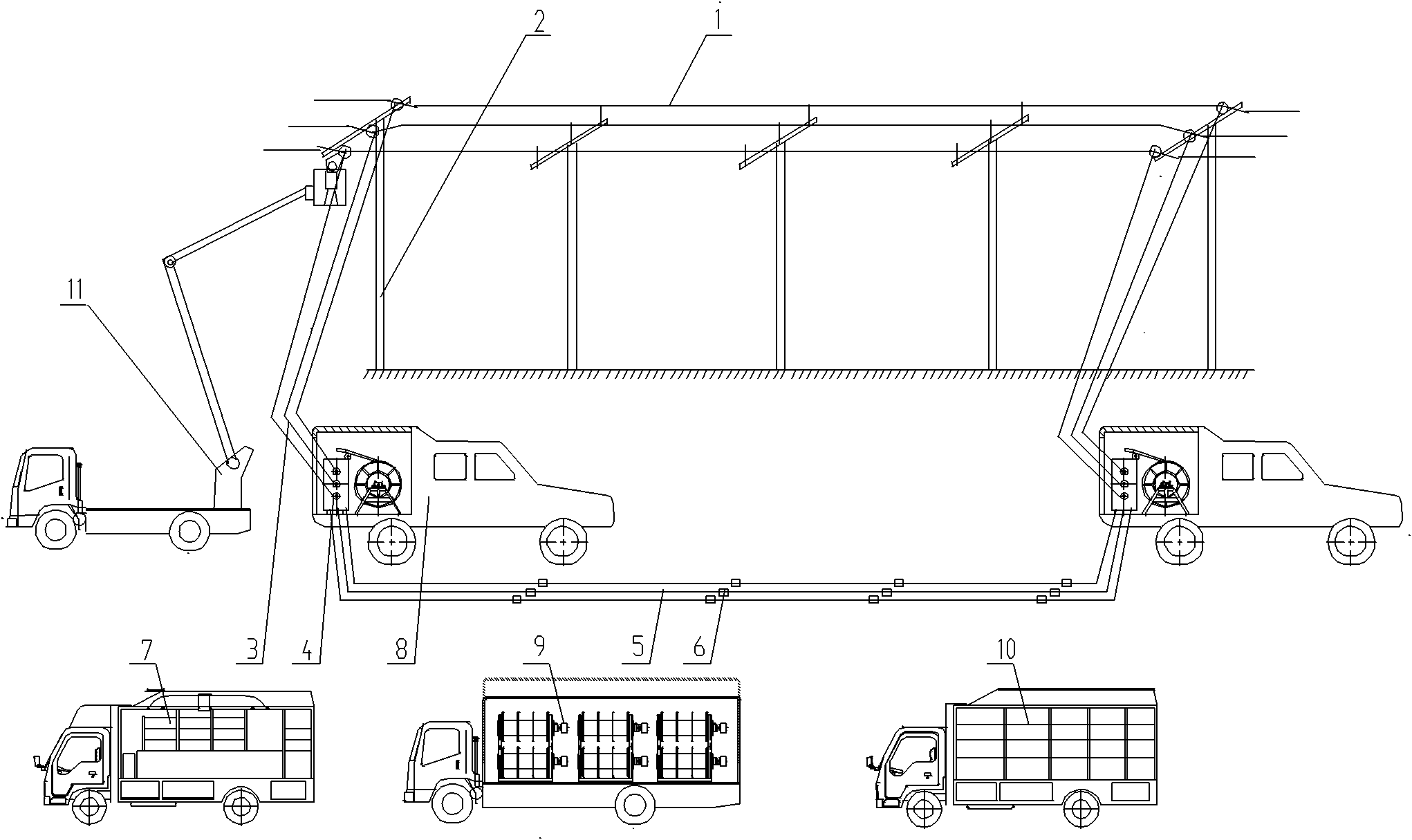

[0019] figure 1 Among them, the special vehicle-based carrying and operating system for bypass live working equipment includes a cable retractable vehicle 9, two load switch vehicles 8, an insulating tool warehouse vehicle 7 and a bypass tool warehouse vehicle 10. A plurality of groups of reel devices capable of automatically rewinding and retracting cables are installed in the cable retracting vehicle 9, and intermediate bypass cables 5 with a length of more than 900 m are stored on the reel devices; load switch 4 and its terminal cable reels are fixedly installed in the load switch vehicle, The terminal cable reel is equipped with a terminal lead-off bypass cable 3; the insulated tool warehouse 7 is equipped with a fast mechanism including a shelf, a drawer or a platform, and the insulated bucket arm truck is stored in the fast mechanism for live work and protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com