Production machine for non-circular workpieces

A non-circular, machine tool technology, applied in the direction of manufacturing tools, controlling mechanical energy, tool holder accessories, etc., can solve the problems that rolling bearings cannot be considered, machine tools are expensive, and are prone to failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

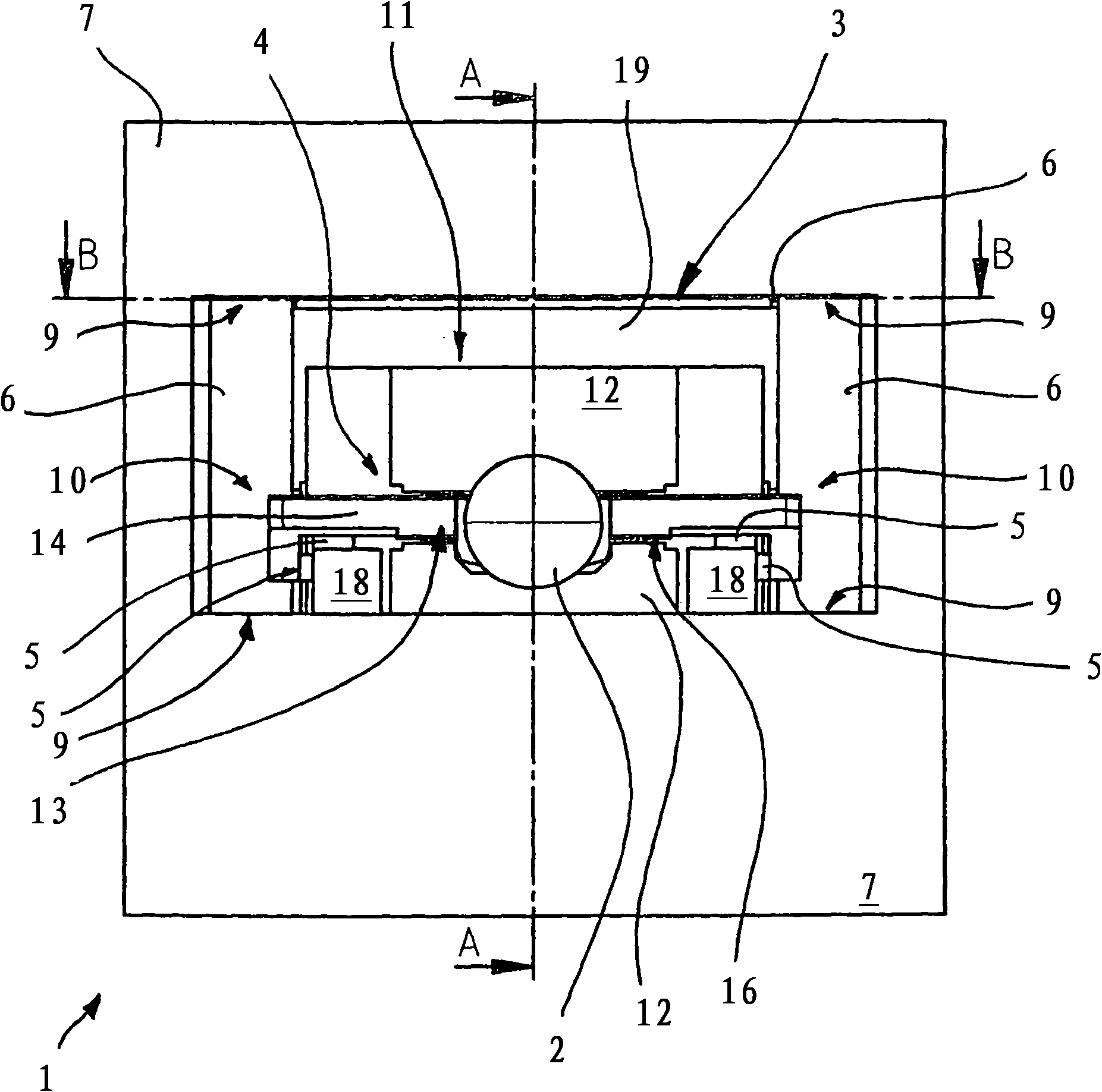

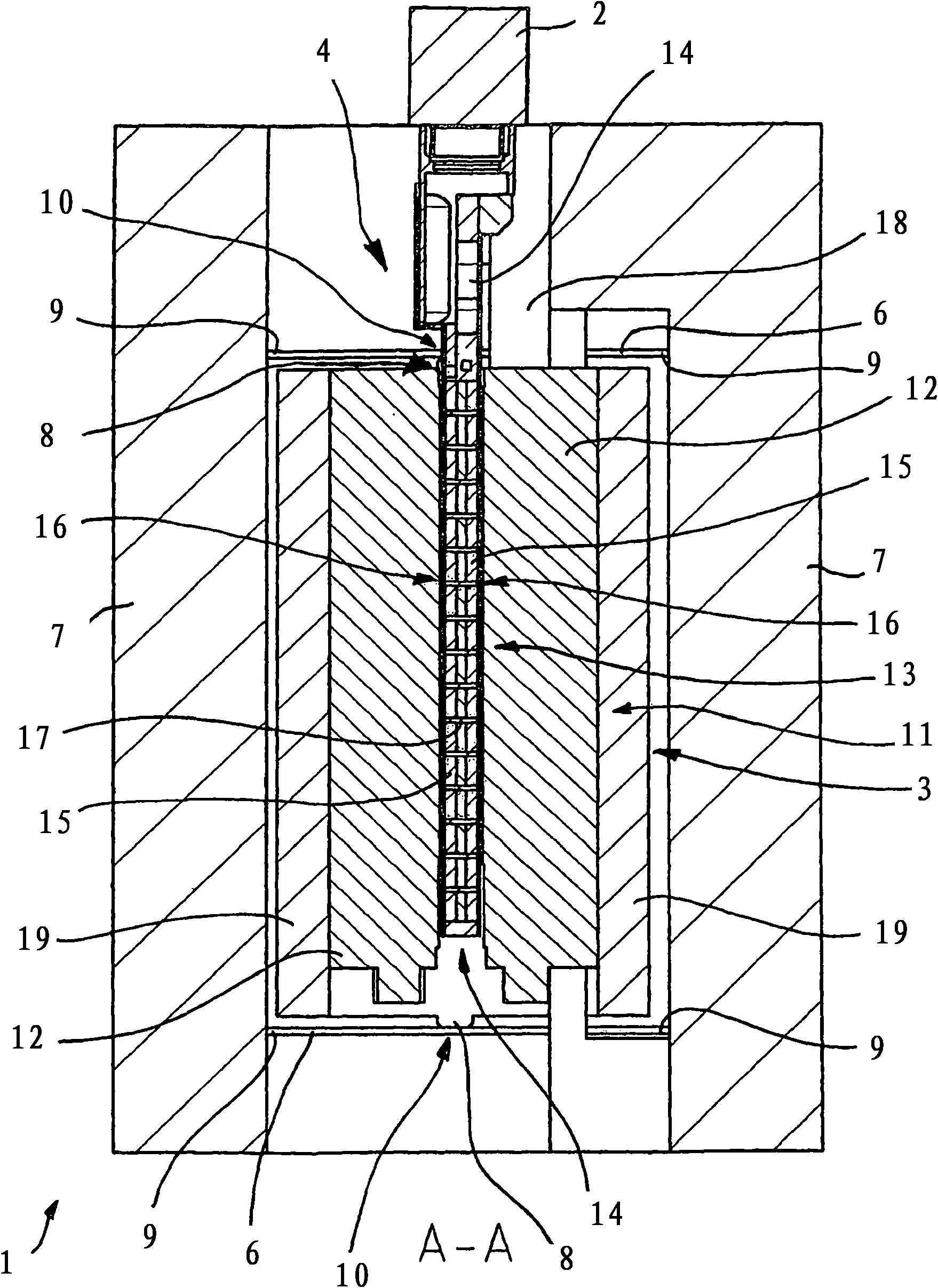

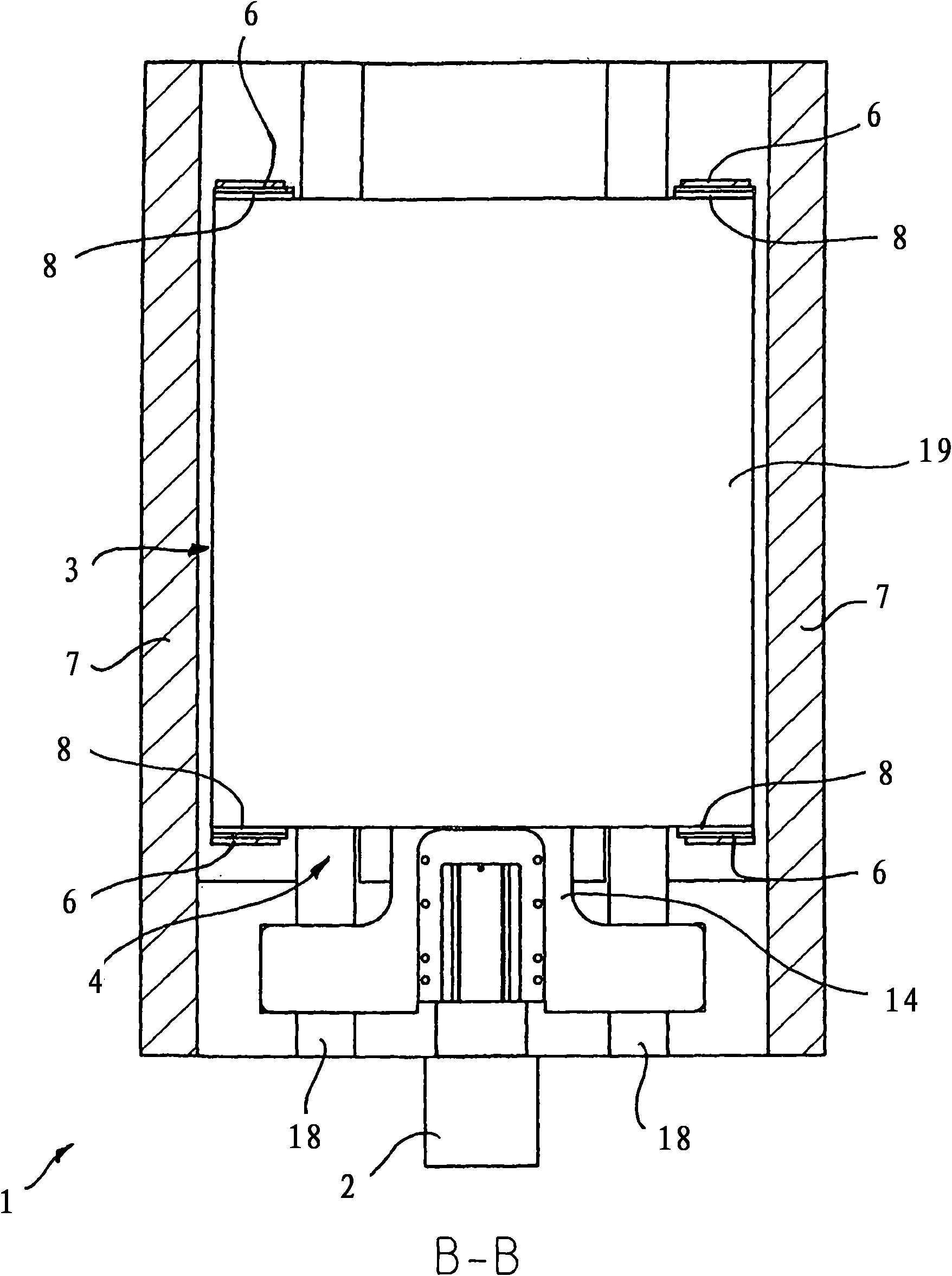

[0032] A tool feed unit, generally designated 1 , of a production machine tool for non-circular workpieces has a tool holder 2 which is designed to receive a tool and is capable of reciprocating movement.

[0033] A compensating body 3 is used for pulse decoupling, wherein the movement of the tool can be triggered or realized by a drive 4 acting between the tool holder 2 and the compensating body 3 . The acceleration of the tool carrier 2 triggered or forced by the drive 4 forms a recoil force which is absorbed by a corresponding movement of the compensating body 3 . The recoil forces thus do not act on other parts of the production machine and thus do not have a negative effect on the machining accuracy.

[0034] The tool holder 2 , which consists of or is connected to several parts, is supported by rolling elements 5 and is guided in such a way that only one degree of freedom of movement remains, namely the advance of the tool clamped on the tool holder 2 .

[0035] The com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com