Electricity-generating element and nonaqueous-electrolyte battery using the same

A technology for power generation elements and solid electrolyte layers, which is applied in the manufacture of non-aqueous electrolyte batteries, non-aqueous electrolytes, and electrolyte batteries, etc., can solve the problem that metal Li does not have electrochemical stability, and achieve excellent cycle characteristics, reduced losses, high Effect of discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

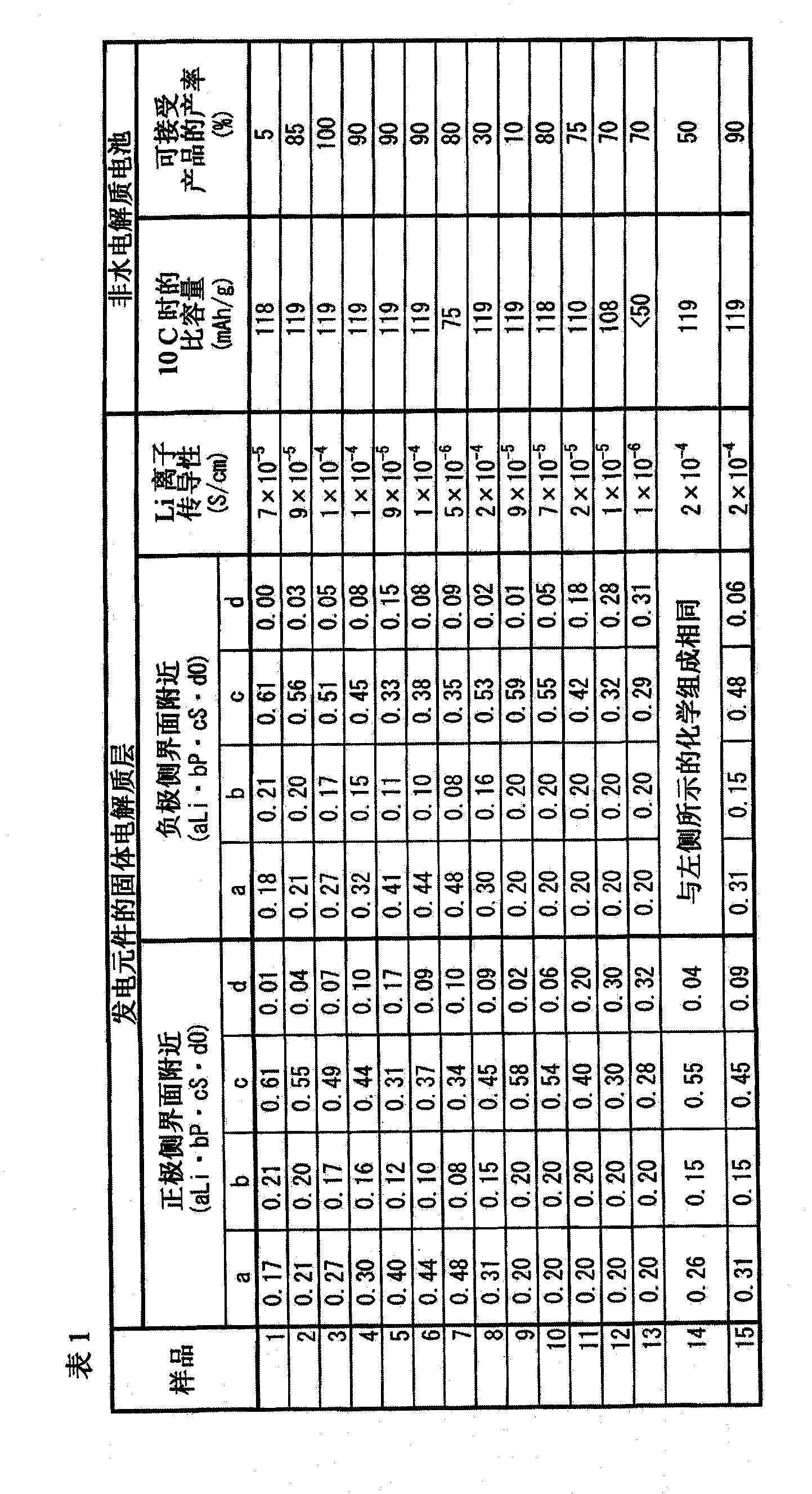

[0069] Hereinafter, power generating elements according to Examples and Comparative Examples were produced. The yield of the power generating element was evaluated. Each power generating element is manufactured by sequentially stacking a positive electrode layer, a solid electrolyte layer, and a negative electrode layer on a substrate to be formed as a positive electrode current collector. The term "yield" as defined herein means the proportion of a battery that retains its capacity after a predetermined number of charge-discharge cycles.

[0070]

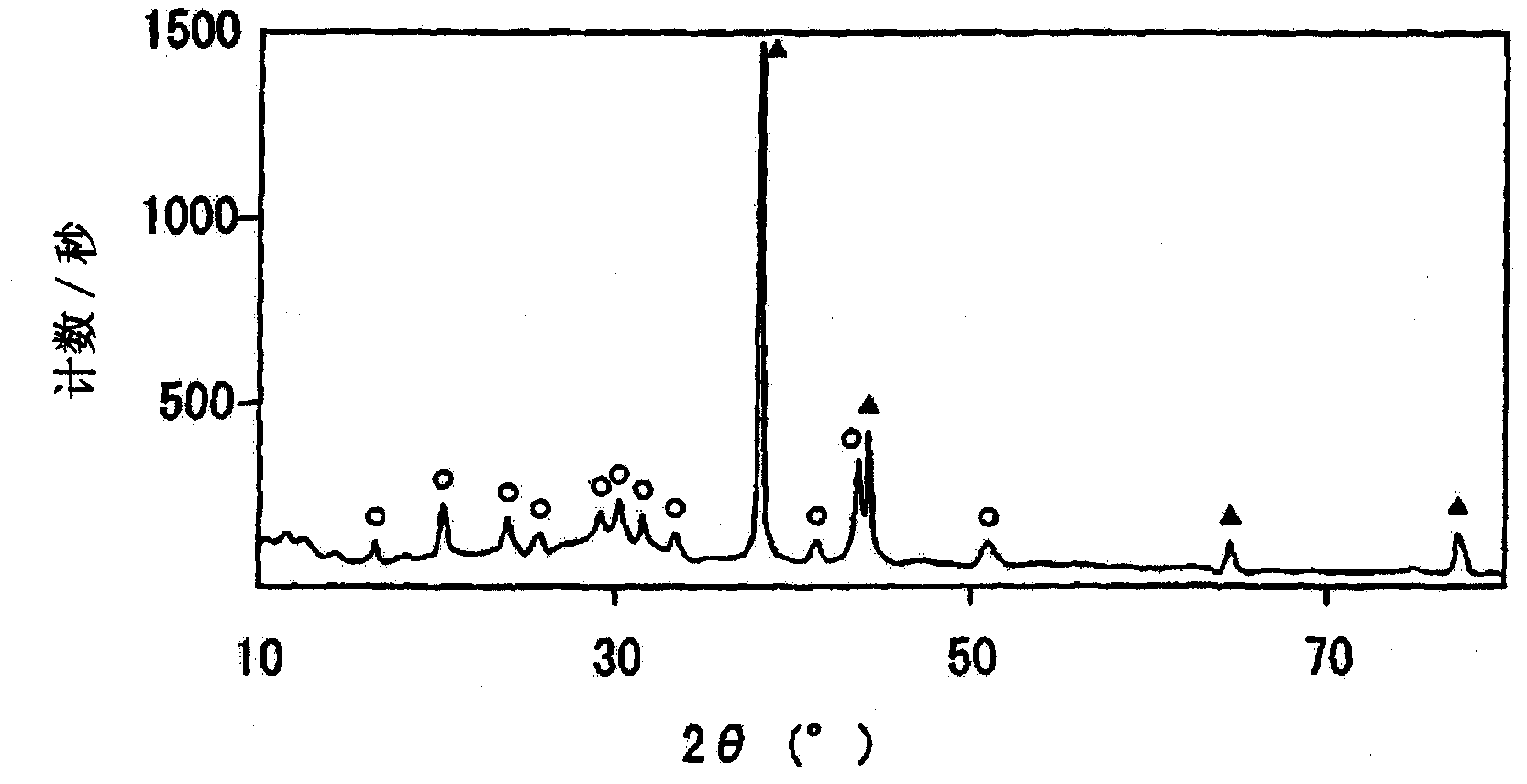

[0071] The stainless steel foil to be formed as the current collector of the positive electrode layer was placed in a vacuum chamber and fixed on a base made of stainless steel, wherein the stainless steel foil was a square of 100 mm×100 mm and a thickness of 100 μm. The surface of the stainless steel foil was cleaned with an Ar ion beam. Next, using a KrF excimer laser, a positive electrode layer containing LiCoO as a positive...

Embodiment 2

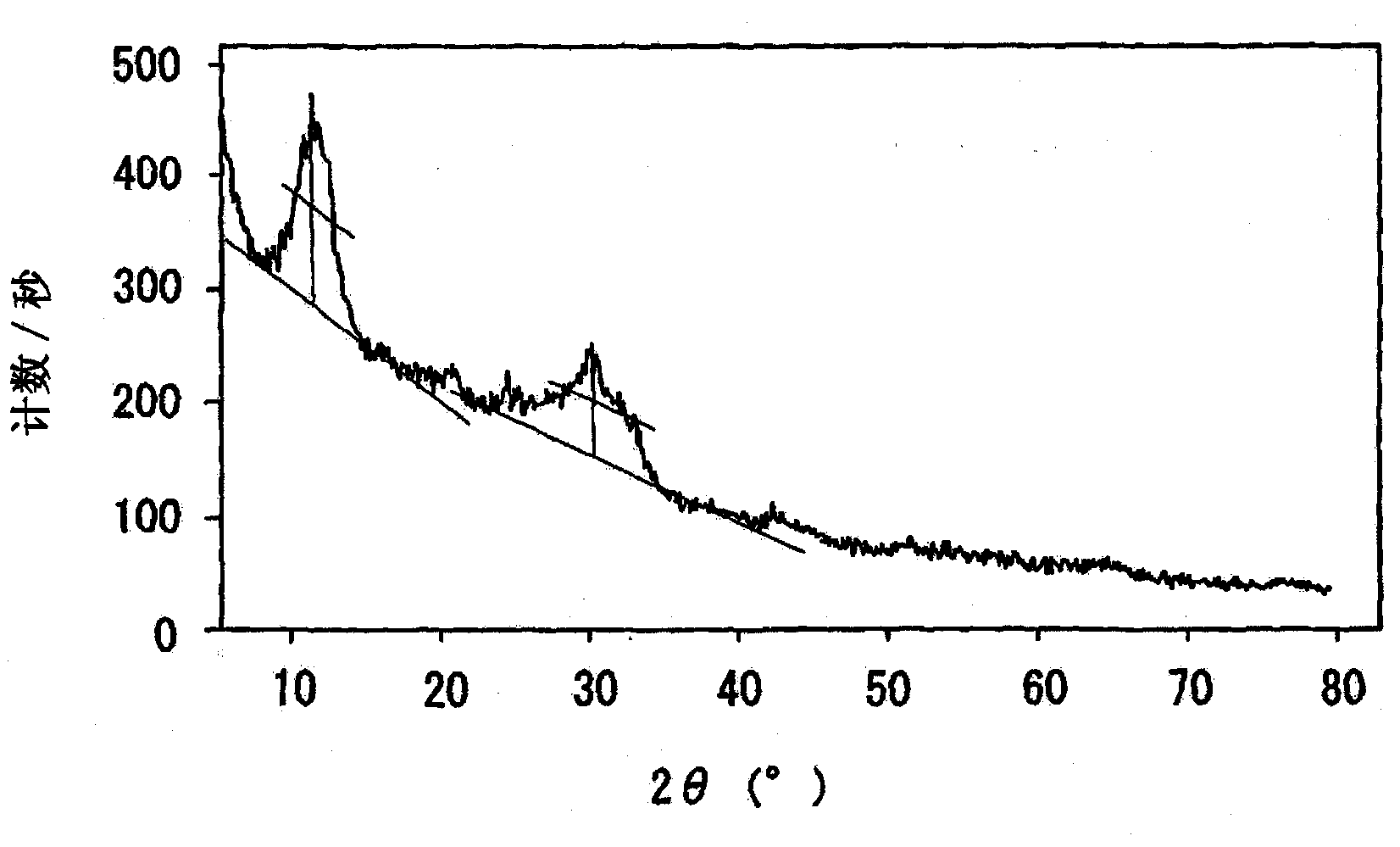

[0096] For power generating elements including solid electrolyte layers with different crystalline states, the specific capacity at 10C and the yield of acceptable products were investigated. In addition, the Li ion conductivity of the solid electrolyte layer in the power generation element was also investigated.

[0097]

[0098] (sample 29)

[0099] Sample 29 of Example 1 was produced. In forming the solid electrolyte layer of Sample 29, the solid electrolyte layer was heat-treated at 225°C. Thus, the solid electrolyte layer may be crystalline.

[0100] (Sample 31)

[0101] Sample 31 was fabricated in the same manner as Sample 29 except as described below.

[0102] The difference is that after the solid electrolyte layer is formed on the positive electrode layer, it is heat-treated at 100° C. for 30 minutes.

[0103] (Sample 32)

[0104] Sample 32 was fabricated in the same manner as Sample 29 except as described below.

[0105] The difference is that no heat treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com