Machining method of thrust face of quenched crankshaft of forging steel fillet

A processing method and thrust surface technology, applied in the field of metal processing, can solve the problems of burns, large thermal deformation, large contact width between the thrust surface and the grinding wheel, etc., and achieve the effect of reducing the processing amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

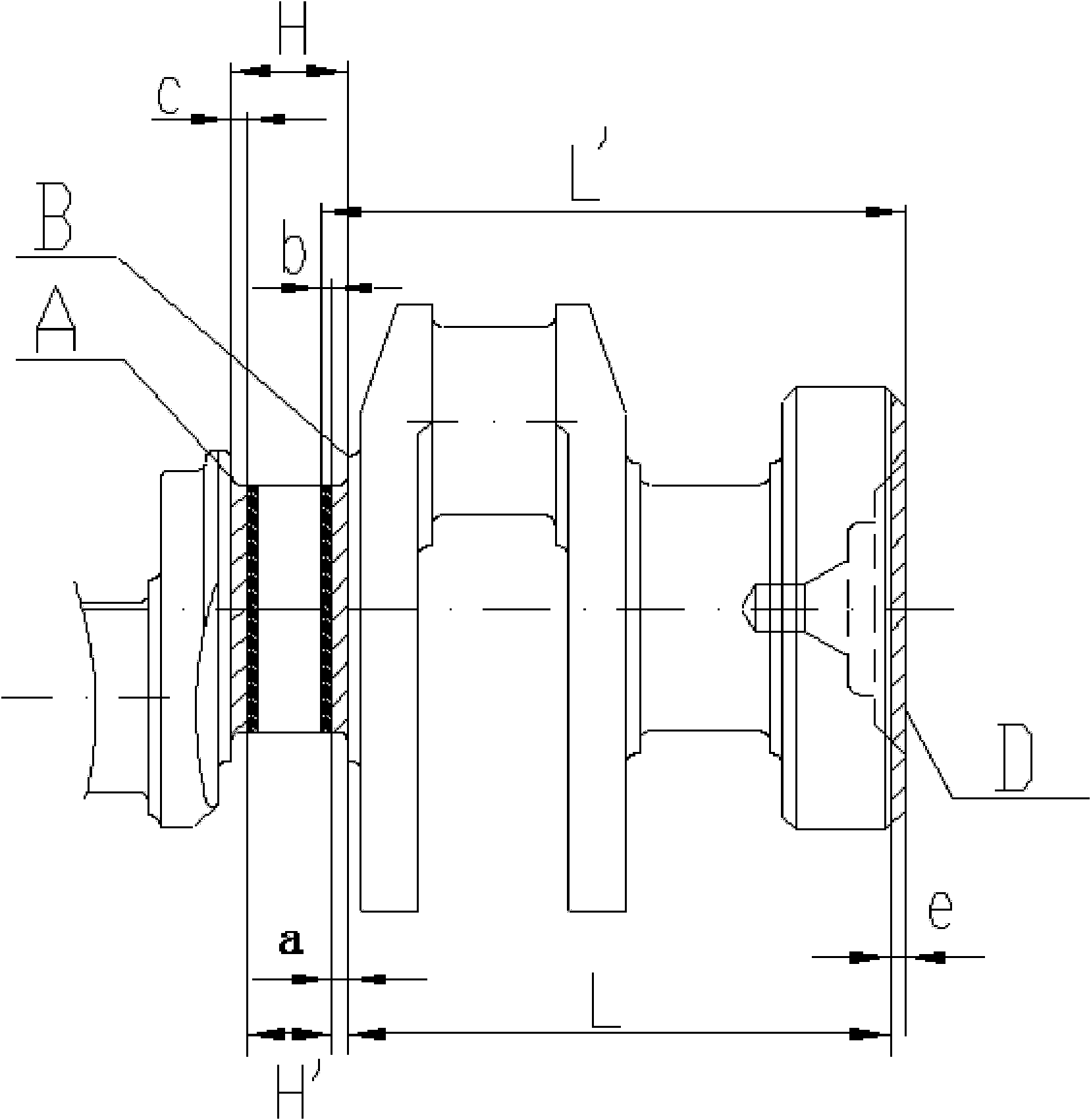

Image

Examples

Embodiment Construction

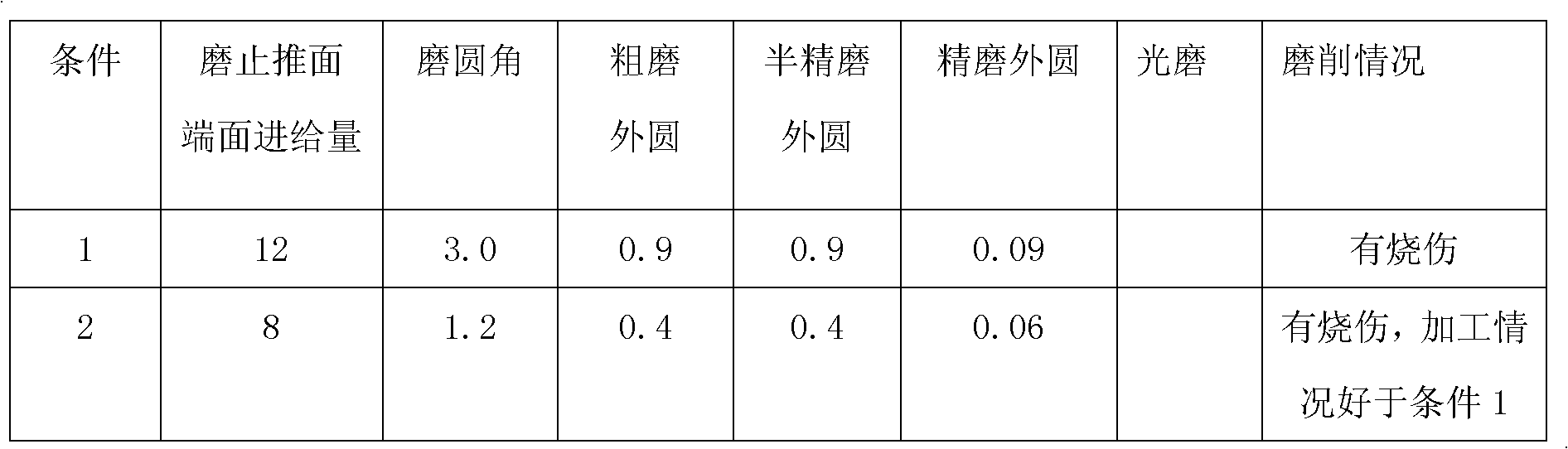

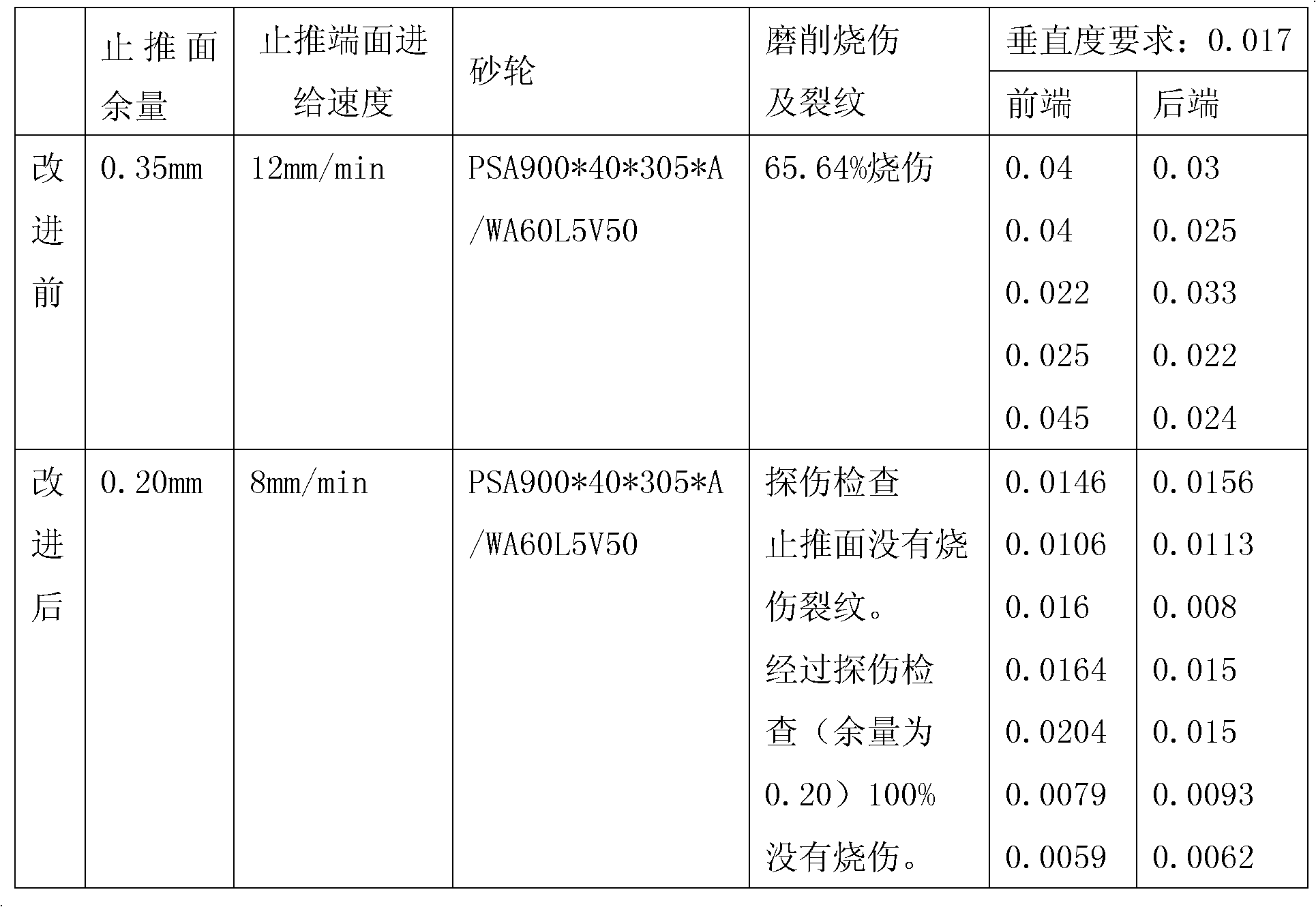

[0030] 1. Determination of the amount of end face grinding:

[0031] The temperature T of the surface layer of the workpiece a For: T a =C*V W 0.2 *a p 0.35 *f -0.3 *v s 0.25

[0032] In the formula: C refers to heat capacity

[0033] V W Refers to the feed speed of the grinding wheel

[0034] a p Refers to the grinding depth (face grinding allowance)

[0035] f refers to the feed rate

[0036] v s Refers to the workpiece rotation

[0037] It can be seen from the formula that the grinding depth a p to T a The greatest impact, followed by the wheel speed. Grinding depth a p (Face grinding allowance) increase, T a increases, the temperature under the surface of the workpiece gradually increases, so a p Can not choose too large.

[0038] According to the statistics, the end jump of the thrust face after the actual quenching is:

[0039] 1) The average value of the reference end is 0.16, and the maximum value is 0.30.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com