Printing press with cylinder adjustment and cylinder conversion device

A conversion device and printing machine technology, applied to rotary printing machines, printing machines, printing, etc., can solve the problem that the pressure of the rolling pillow cannot be kept constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

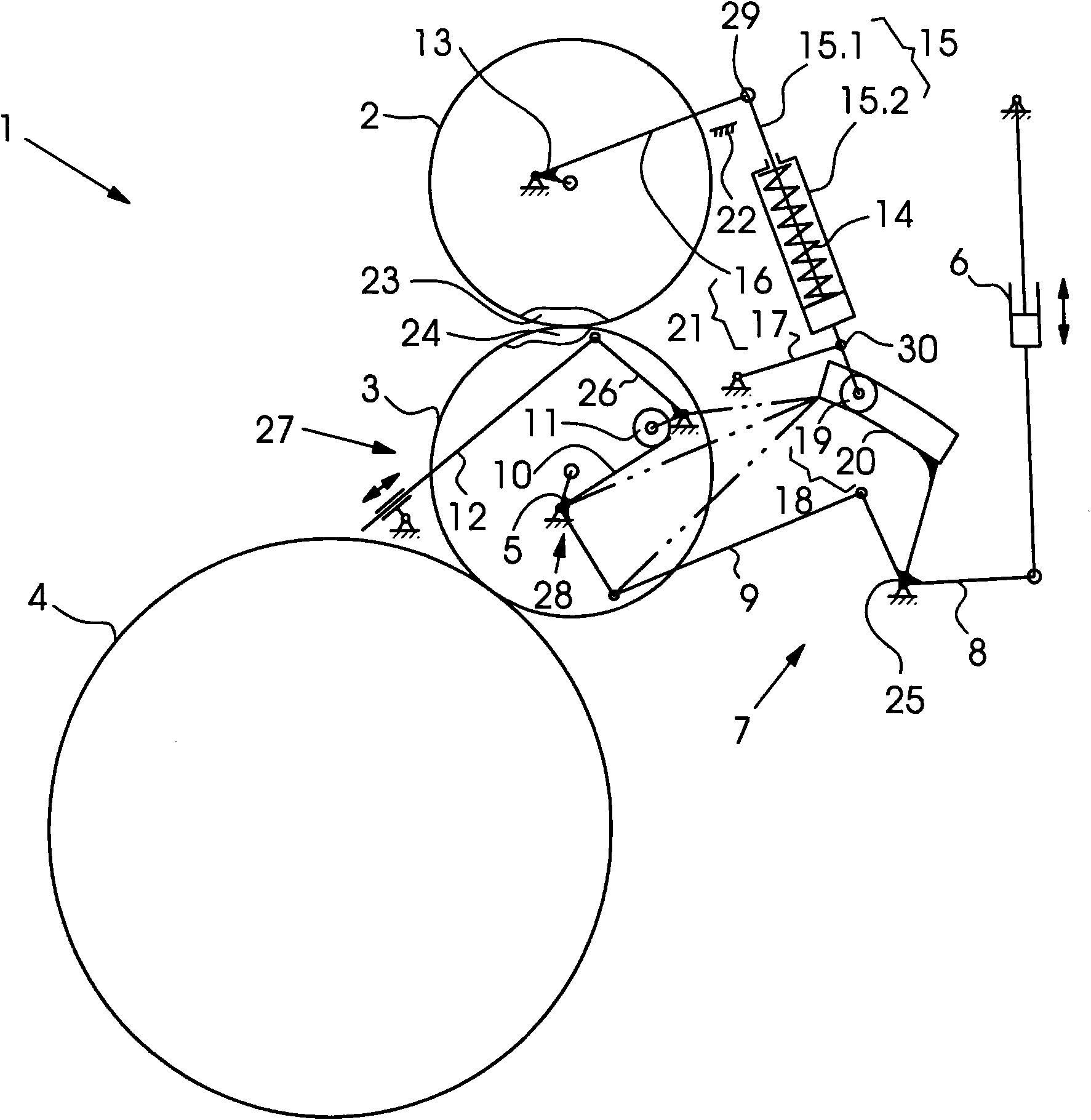

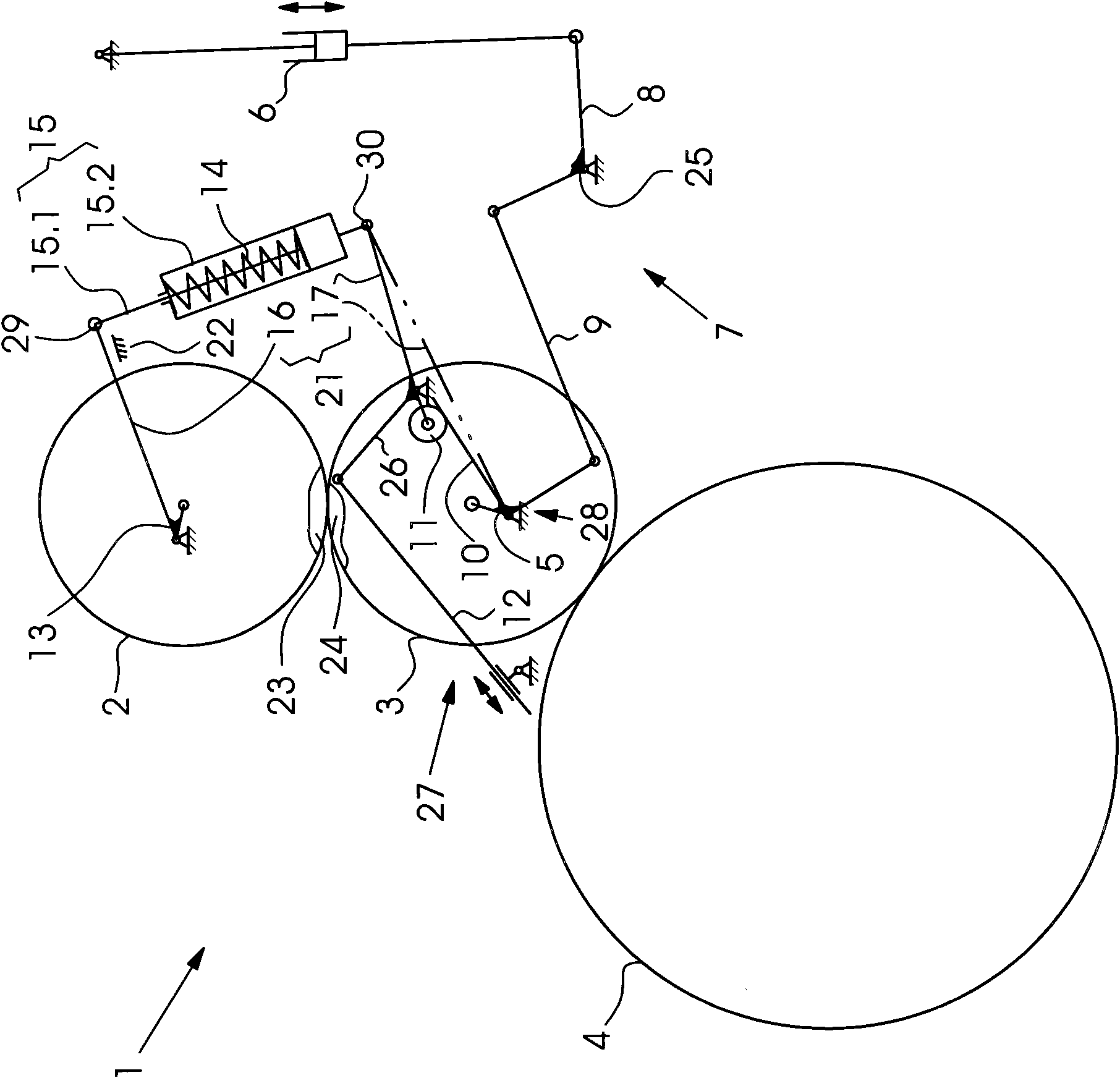

[0014] exist figure 1 and 2 In , members and elements corresponding to each other are provided with the same reference numerals.

[0015] exist figure 1 A printing press 1 for lithographic offset printing on printing sheets is shown in FIG. The printing press 1 comprises a plate cylinder 2 , a blanket cylinder 3 and an impression cylinder 4 . The blanket cylinder 3 is mounted in a first eccentric bearing 5 , by adjusting the eccentric bearing, the blanket cylinder 3 can optionally be adjusted into an initial printing position and an end printing position. The first eccentric bearing 5 is an integral part of a switching device 28 for switching the blanket cylinder 3 relative to the impression cylinder 4 at the start of printing and at the end of printing. The adjustment of the eccentric bearing 5 is driven by a pneumatic cylinder 6 via a four-joint transmission 7 .

[0016] The four-hinge transmission device 7 includes a double-arm driving rocker 8 , a connecting rod 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com