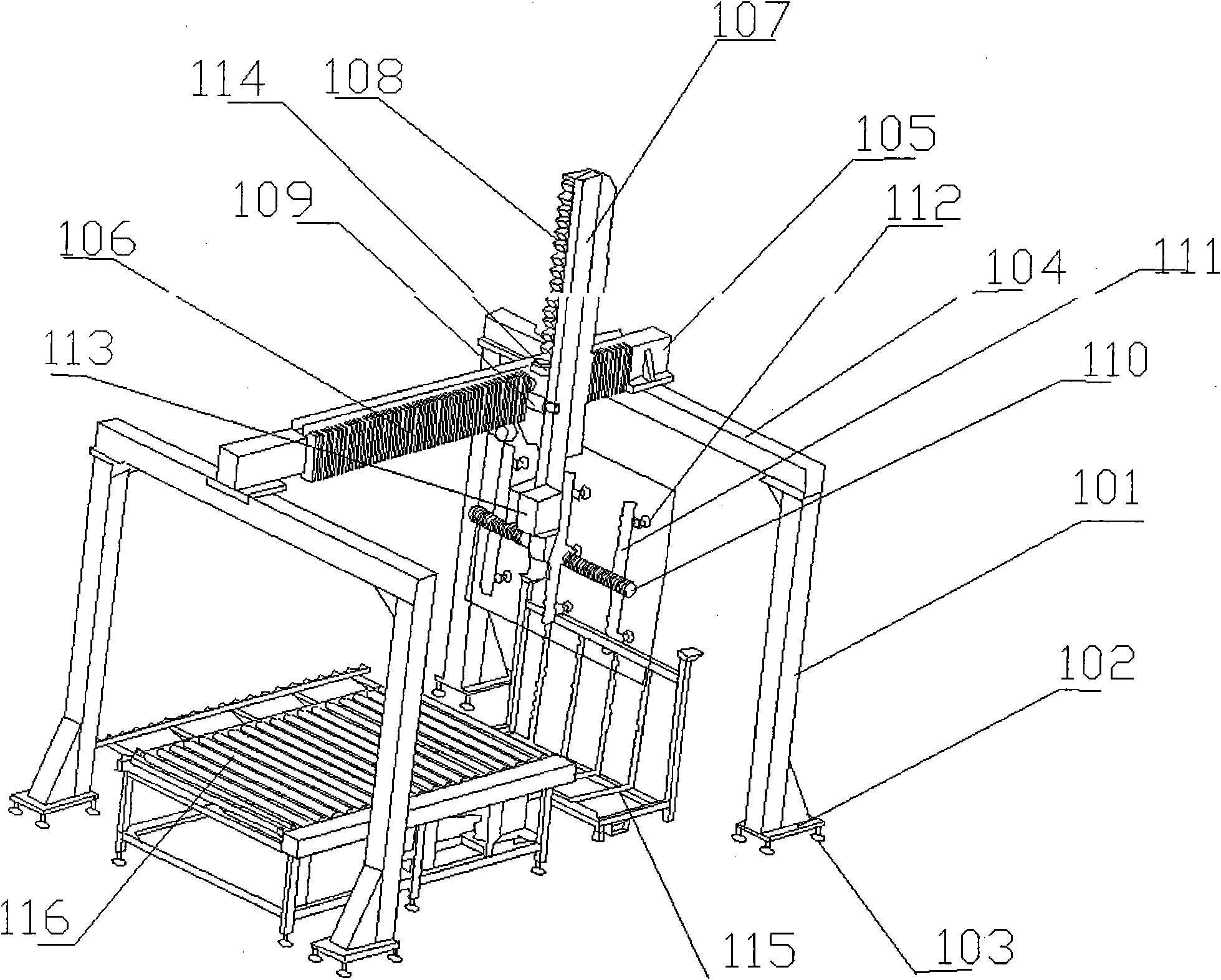

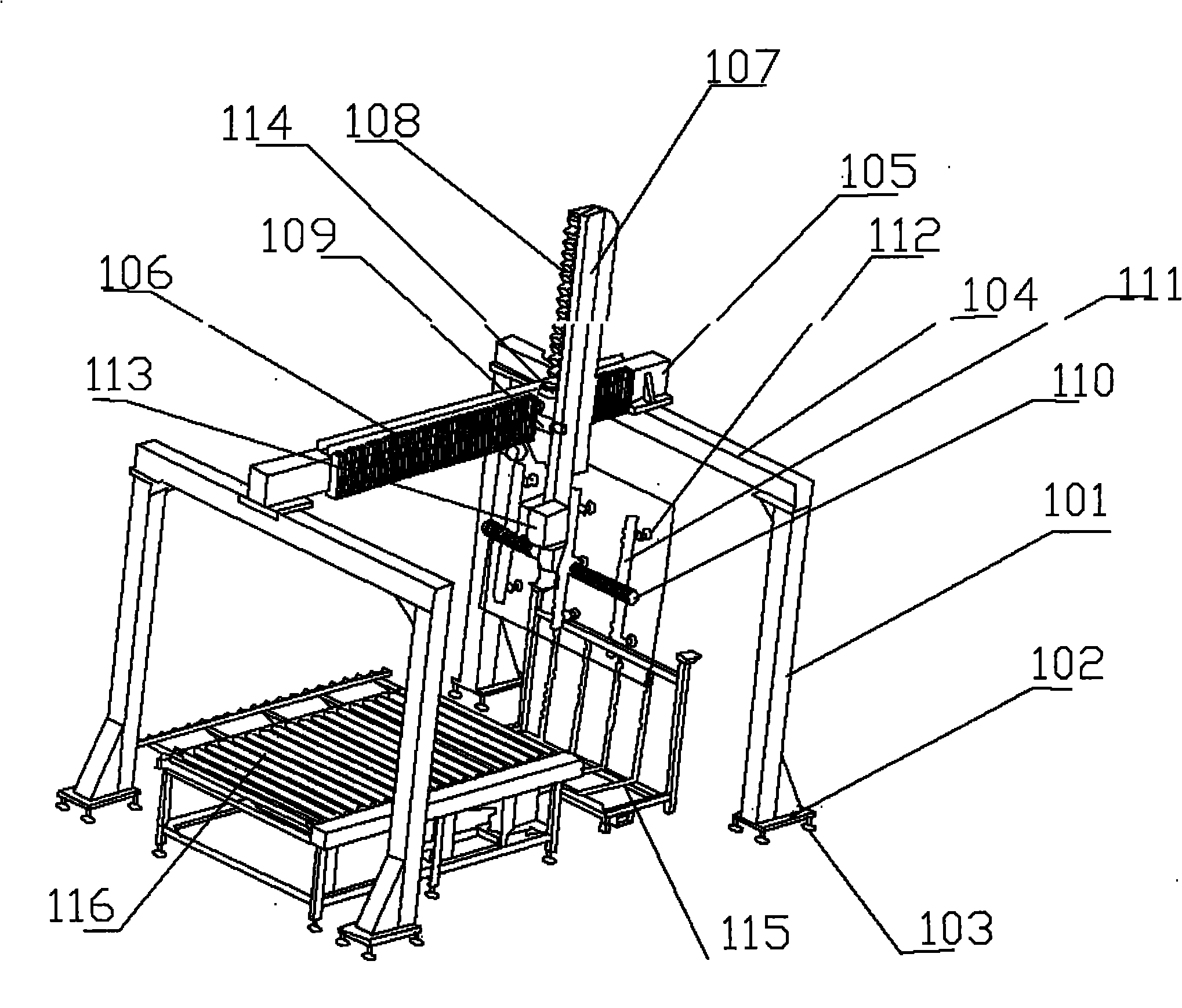

Traveling sucking disc assembling and disassembling bench

A technology of suction cups and sheet tables, which is applied in the field of glass processing machinery for loading and unloading sheets, can solve problems such as dependence, and achieve the effect of improving work efficiency and work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, the glass loading function, the operator moves the present invention to the designated working position, because the support walking roller 103 is installed under the support base 102 of the support 101, it is convenient to adjust the working position, and the glass storage rack 116 for storing glass is placed To the station, the present invention is adjusted between the glass storage rack 116 and the glass operation line 115, controlled by the control device, when the glass sheet needs to be loaded, the horizontal travel controller 109 controls to move to the corresponding position, and the longitudinal travel controller 108 adjusts up and down In the proper position, the turning controller 113 controls the turning arm 110 to rotate counterclockwise by 90 degrees, and drives the turning arm support 111 connected to it to turn over. The glass suction cup 112 on the turning arm support 111 sucks the glass on the glass storage rack 116, and then controls the v...

Embodiment 2

[0018] Embodiment 2, the glass unloading function, after the glass is processed, it needs to be stored on the glass support 116, and the turning arm 110 is controlled to turn clockwise by 90 degrees through the turning controller 113, which drives the turning arm support 111 to turn over synchronously, and the turning arm support The glass sucker 112 on the 111 is also turned over synchronously, the lateral travel controller 109 is displaced to the working position, and the longitudinal travel controller 108 controls the longitudinal displacement rod 107 to drop to a designated position, so that the glass sucker 112 on the flip arm support 111 absorbs the glass and travels longitudinally. The controller 108 controls the longitudinal displacement rod 107 to rise, and the flipping controller 113 controls the flipping arm 110 to flip 90 degrees counterclockwise, which drives the flipping arm bracket 111 to flip synchronously, and the glass sucked by the glass suction cup 112 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com