Rubber stopper or aluminum-plastic cover feeding device

A technology of feeding device and aluminum-plastic cover, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of complicated transfer process, high manufacturing cost, high cost, etc., achieve simple feeding process, reduce pollution opportunities, and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, rubber stopper or aluminum-plastic cap feeding device

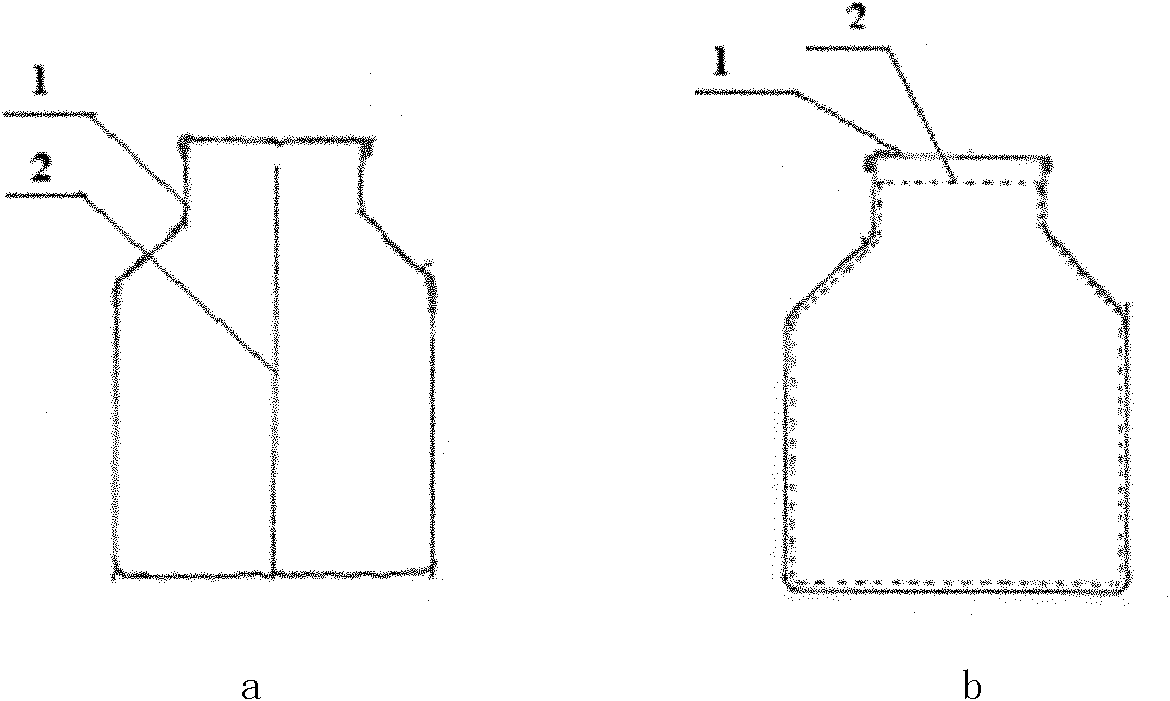

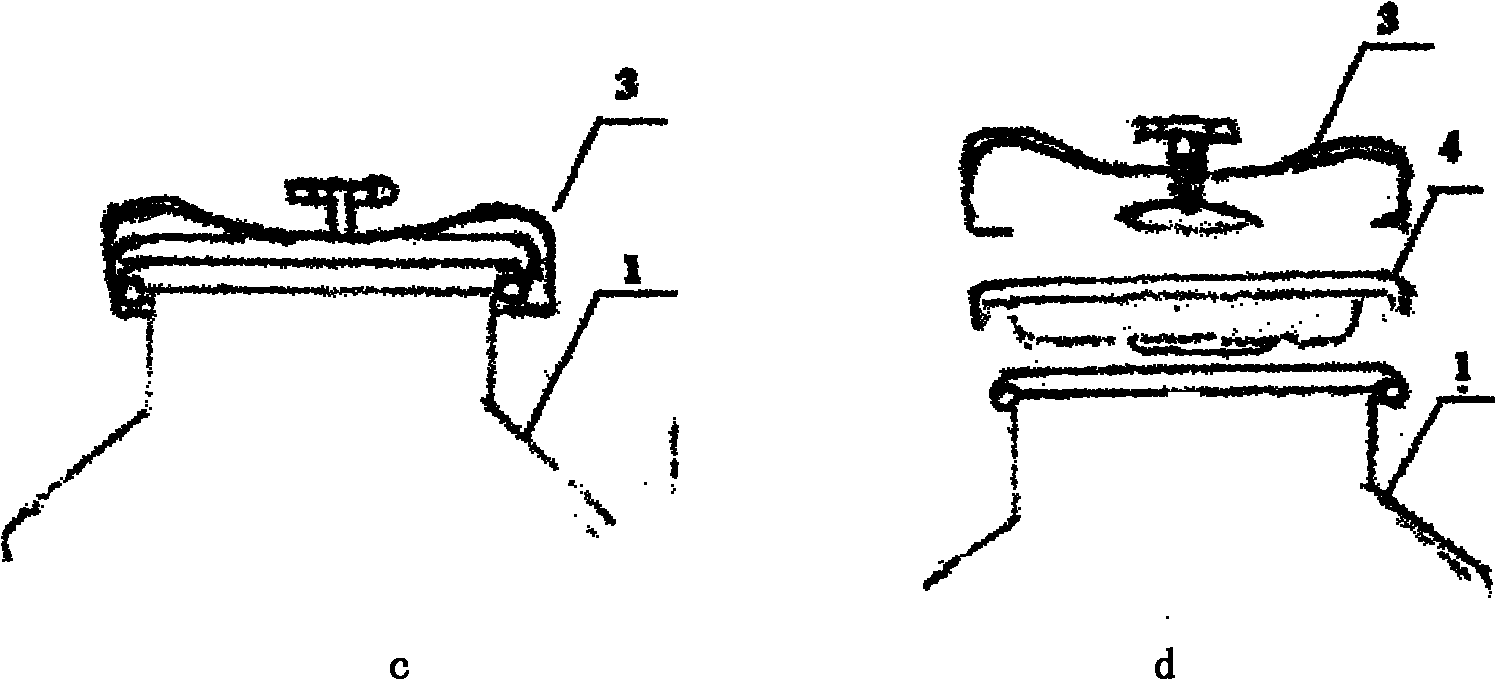

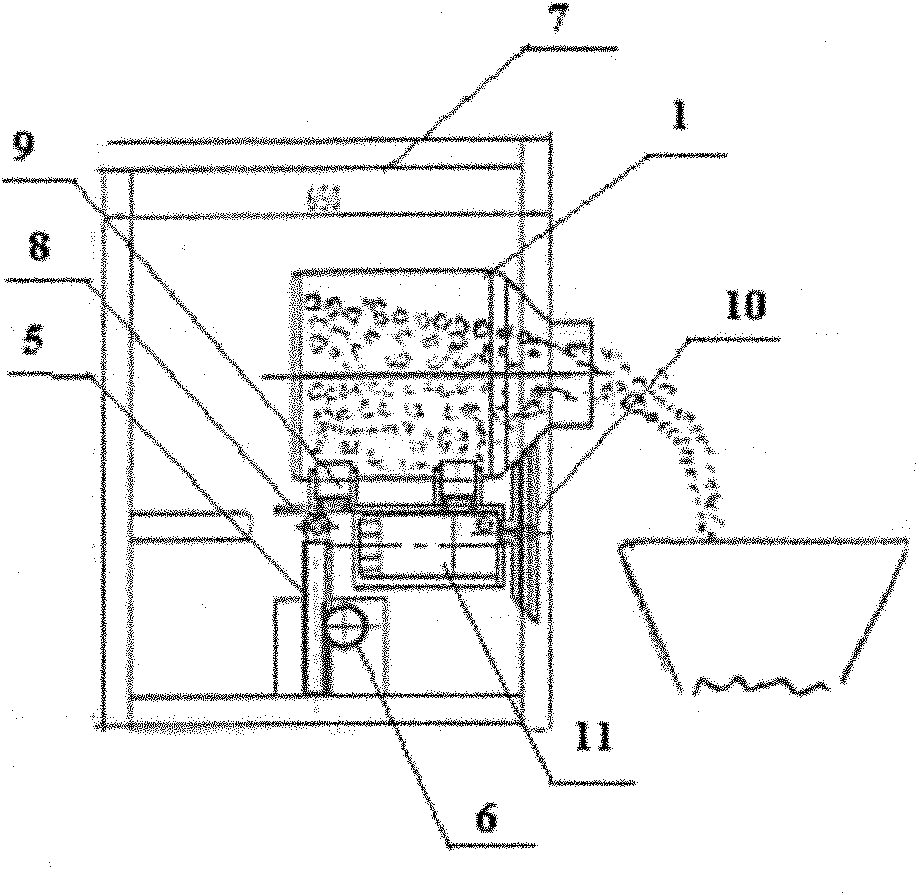

[0023] The device of the present invention is as Figure 1-3 As shown, the marks in the figure are as follows: 1 bottle type running barrel, 2 partitions, 3 clips, 4 barrel cover, 5 racks, 6 rotating gears, 7A-level laminar flow carts, 8 brackets, 9 passive rollers, 10 Tower wheel, 11 motors, 12 universal wheels.

[0024] The rubber plug or aluminum-plastic cap feeding device provided by the present invention comprises a bottle-shaped running bucket 1, which is provided with a bung 4, which can be closely matched with the bottle-shaped running bucket 1, and the bung 4 is connected to the bottle-shaped running bucket 1. Type running barrel 1 can also be further sealed and matched by clip 3 to ensure the aseptic environment in bottle-shaped running barrel 1; bottle-shaped running barrel 1 is provided with a partition 2 along the axial direction, and this partition 2 will bottle-shaped The running buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com