LED module-based random matrix lamp mixing method and system device thereof

A technology of LED modules and random matrix, which is applied to lighting devices, components of lighting devices, light source fixing, etc., can solve the problems of LED manufacturers who cannot mix lights and lights, and achieve traceability and control The effect of production risk, ease of operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

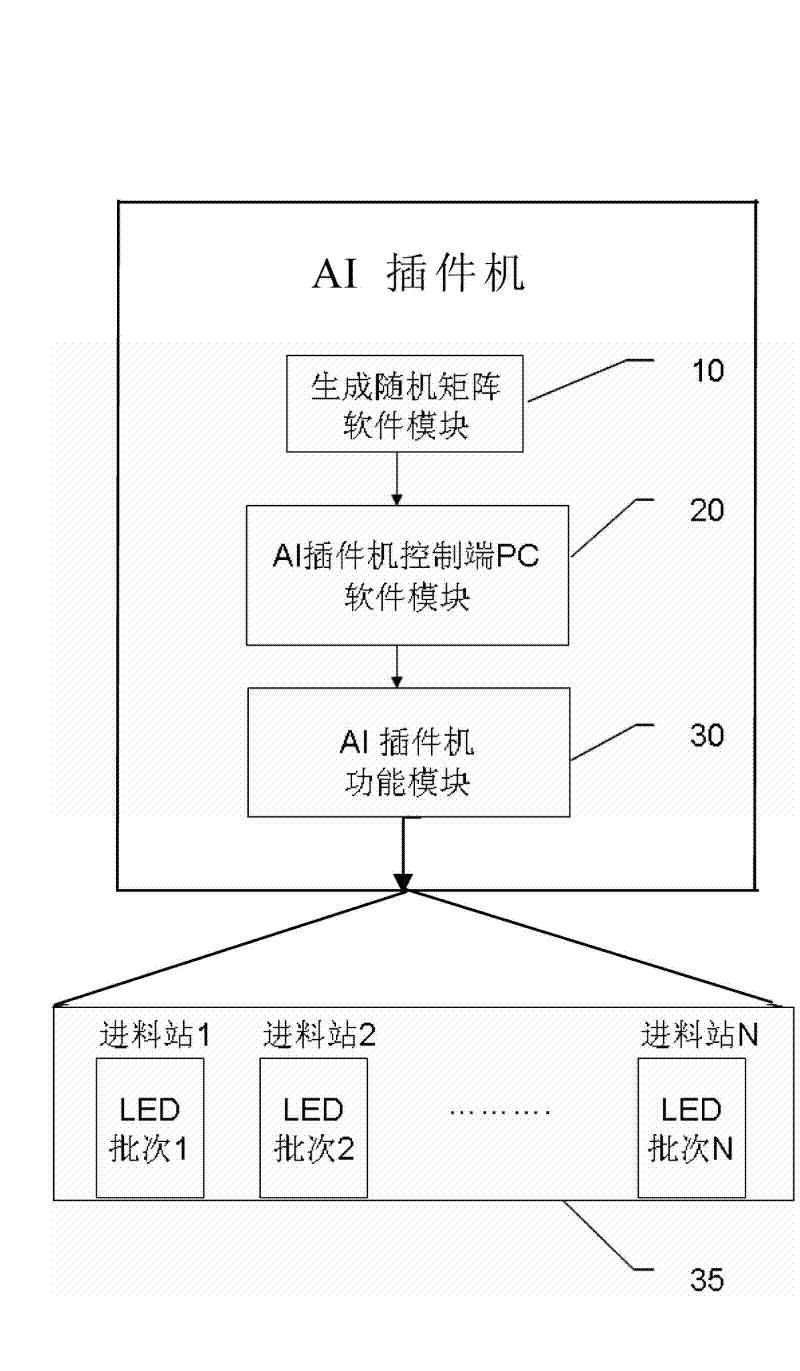

[0033] refer to figure 1 As shown, the system device 1 for realizing the random matrix mixed lights of LED modules in the present invention mainly includes an AI plug-in machine 1 for plugging in LED modules. Construction: a software module 10 for generating a random matrix according to the batch number and quantity of LED lamps processed in real time; a software module 10 for establishing a one-to-one correspondence between the number of the feeding station and the pixels of the LED module An AI plug-in machine control terminal software module 20; an AI plug-in machine function module 30 that establishes the corresponding relationship between LED batches and feeding station numbers.

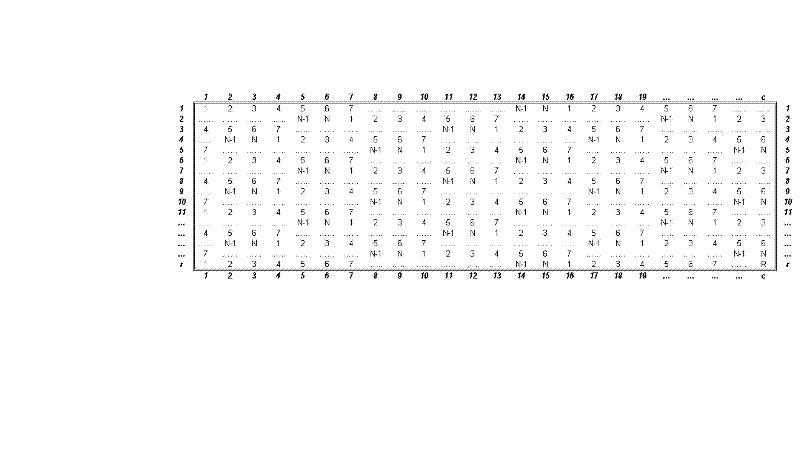

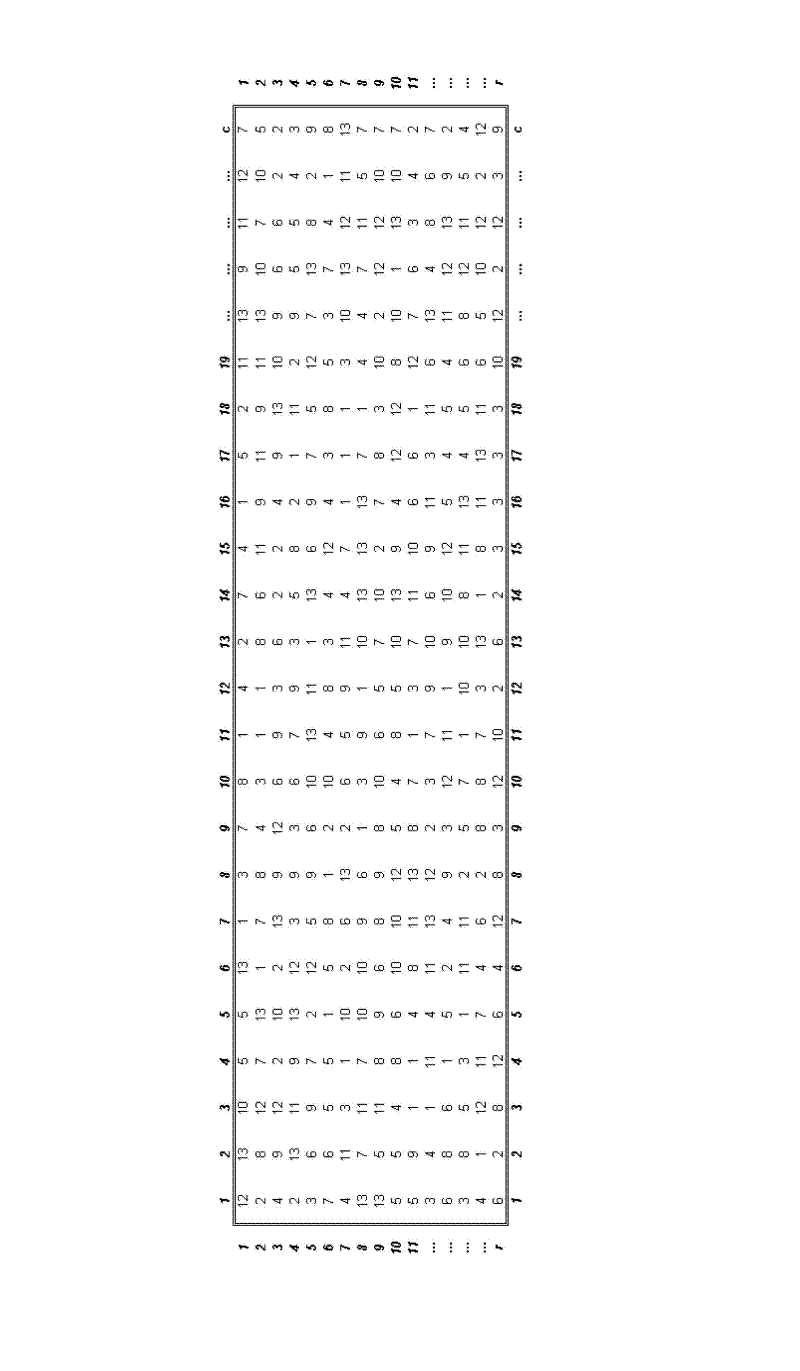

[0034] The invention develops the system device, which can further realize the random matrix mixing of LED modules. Its specific innovation lies in: taking a single LED display module as a unit, according to the batch and quantity of LED lamps used in this batch of production, using the softwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com