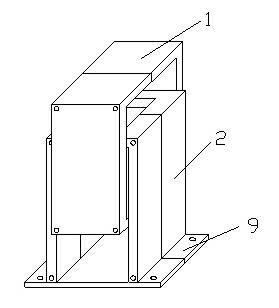

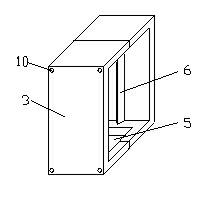

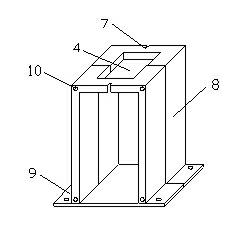

Fixture of test piece for testing inter-laminar drawing fatigue of pavement and testing method thereof

A technology of pavement interlayer and testing method, which is applied in the direction of testing material strength by applying repetitive force/pulsation force, testing material strength by applying stable tension/compression, and measuring devices, which can solve discrete small problems and achieve discrete Small size, strong operability and repeatability, and stable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] 3. Put the specimen into the pull-out fatigue fixture. It should be ensured that the tensile surface of the specimen is perpendicular to the loading surface.

[0047] 4. Conduct interlaminar pull-out strength test. The specimen is loaded through the upper fixture at a loading rate of 1 mm / min until it fails. After the test, it will be obtained as image 3 As shown in the load-deformation curve, the failure load of the specimen can be taken as 80% of the ultimate load. From this, the interlaminar pull-out strength of the specimen is obtained as: , where P is the failure load of the specimen, and A is the cross-sectional area of the specimen. In order to ensure the accuracy of the experimental results, three parallel experiments were carried out, and the test results are shown in Table 1. In this test, a cylindrical core sample with a diameter of 150 mm is used, among which the height of the asphalt concrete specimen is 100 mm, the height of the cement stabilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com