Method for detecting mechanical scratching condition of silicon wafers

A detection method and technology for silicon wafers, applied in the directions of optical testing flaws/defects, semiconductor/solid-state device testing/measurement, etc., can solve problems such as difficulty in judging the source machine, yield loss, and time-consuming detection methods, reducing Victimize batches, improve yield, avoid time-consuming and blind effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

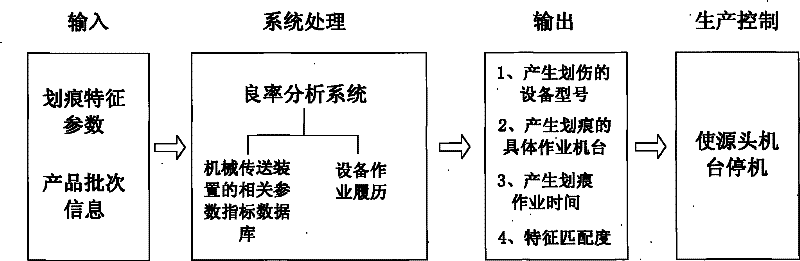

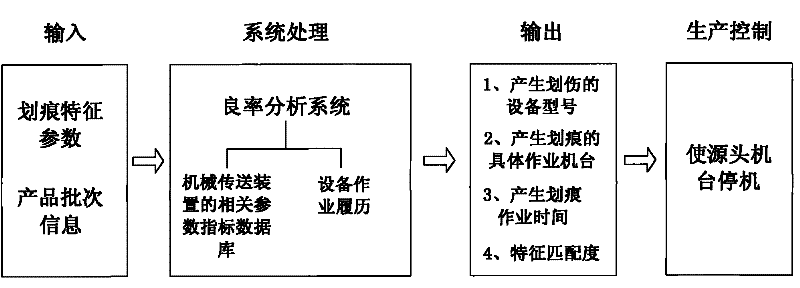

[0022] The method for detecting mechanical scratches on silicon wafers of the present invention uses the following steps to detect the source of mechanical scratches on silicon wafers:

[0023] 1. Establish the characteristic information database of the mechanical conveying device of the silicon wafer conveying device on the silicon wafer production line;

[0024] Since there are dozens of actual types and sizes of the manipulators of the mechanical transmission device, the scratch sizes caused by different types of manipulators are also different.

[0025] The mechanical transfer device includes all relevant parts (manipulators, conveyor belts, etc.) Detailed dimensions of possible scratches on the part;

[0026] 2. When mechanical scratches are detected on a certain batch of silicon wafers on the production line, the characteristic parameters of the silicon wafer scratches are collected, including the number of the scratched silicon wafers, the angle, length, and intercept ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com