Diaphragm and nonaqueous electrolyte battery

A non-aqueous electrolyte and separator technology, applied in non-aqueous electrolyte batteries, battery electrodes, battery pack components, etc., can solve problems such as inability to obtain performance, achieve excellent impregnation characteristics and liquid retention characteristics, and improve battery characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0028] 1. First Embodiment (Structure of Diaphragm)

[0029] 2. Second Embodiment (Example of Cylindrical Battery)

no. 3 approach

[0030] 3. Third Embodiment (Example of Flat Battery)

[0031] 1. First Embodiment

[0032] Hereinafter, a separator according to a first embodiment of the present invention is described.

[0033] (1-1) Structure of diaphragm

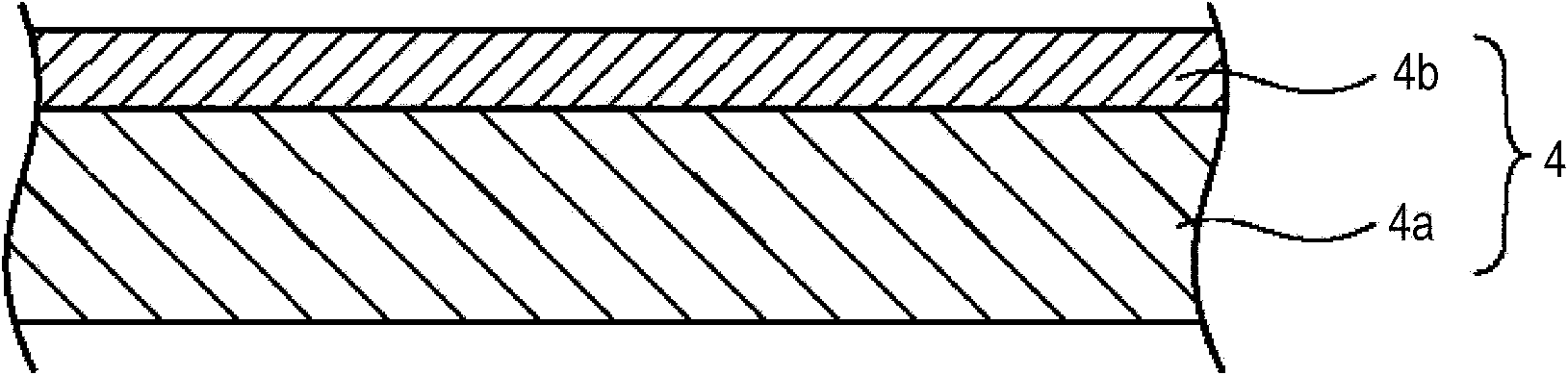

[0034] The separator 4 separates the positive electrode and the negative electrode from each other and allows lithium ions to pass therethrough while preventing short circuiting of current due to contact between the two electrodes. Such as figure 1 As shown, the separator 4 is composed of a base material layer 4a and a functional resin layer 4b. The base material layer 4a may be provided if necessary, and the separator 4 may be composed of only the functional resin layer 4b.

[0035] [Base material layer]

[0036] The base material layer 4a is composed of a microporous film made of polyolefin resin. Examples of polyolefin resins that can be used include polyethylene (PE), polypropylene (PP), and mixtures of these polyolefin resins. The polyolefin ...

no. 2 approach

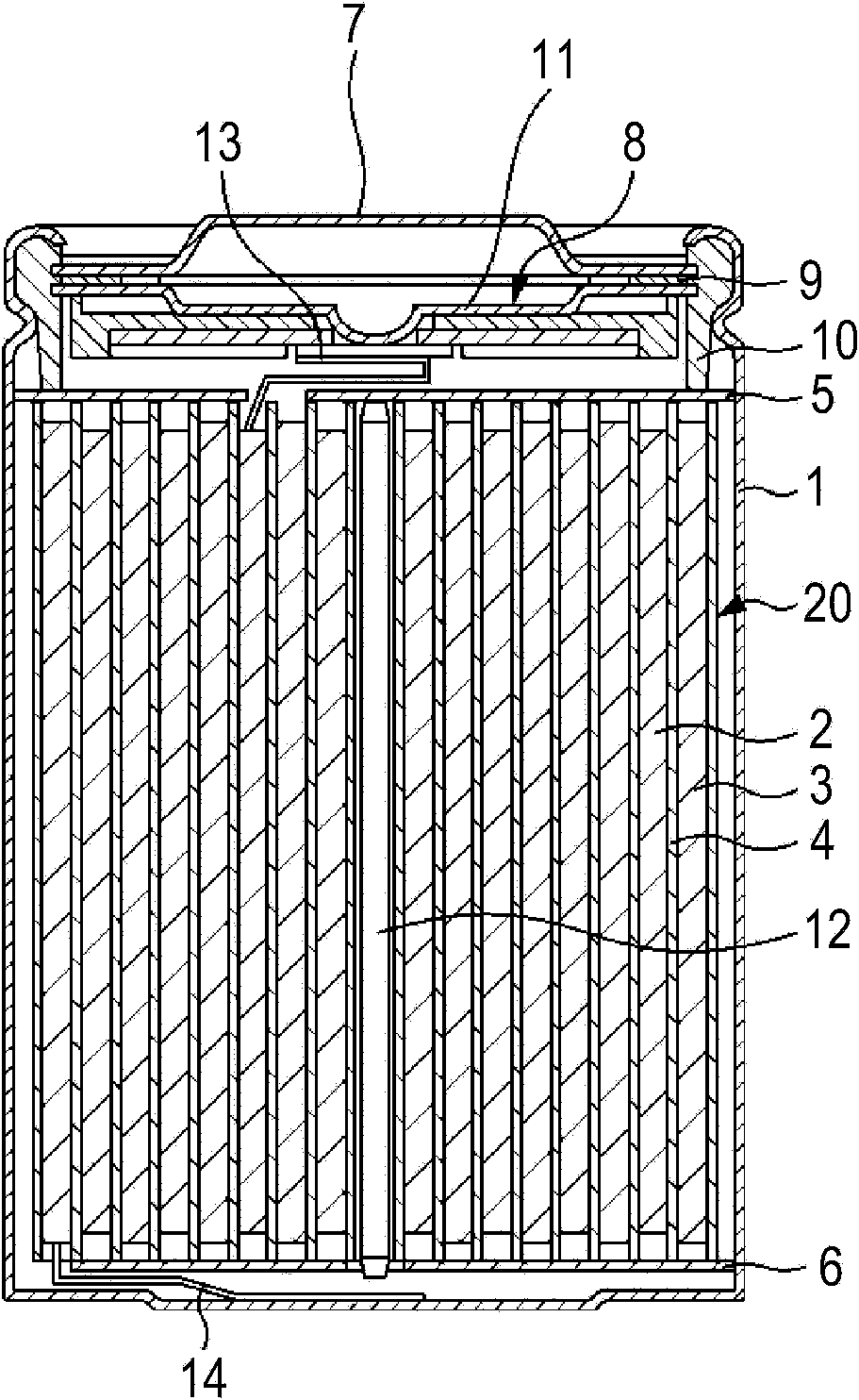

[0079] In a second embodiment according to the present invention, a nonaqueous electrolyte battery using the above separator is described with reference to the drawings. image 3 A cross-sectional structure of a nonaqueous electrolyte battery according to a second embodiment of the present invention is shown.

[0080] (2-1) Structure of non-aqueous electrolyte battery

[0081] This nonaqueous electrolyte battery is of a so-called cylindrical type and has a wound electrode body 20 having a strip-shaped positive electrode 2 wound via a separator 4 and a strip-shaped positive electrode 2 inside a substantially hollow cylindrical battery case 1 . Negative pole 3.

[0082] The battery case 1 is made of, for example, nickel (NI)-plated iron (Fe), and one end thereof is closed and the other end is open. Inside the battery case 1 , a pair of insulating plates 5 and 6 are arranged perpendicularly to the wound peripheral surface, respectively, so as to sandwich the wound electrode bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com