Valve train for gas exchange valves of an internal combustion engine having double-supported cam carriers

A technology of valve mechanism and support, applied in the direction of engine components, machines/engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

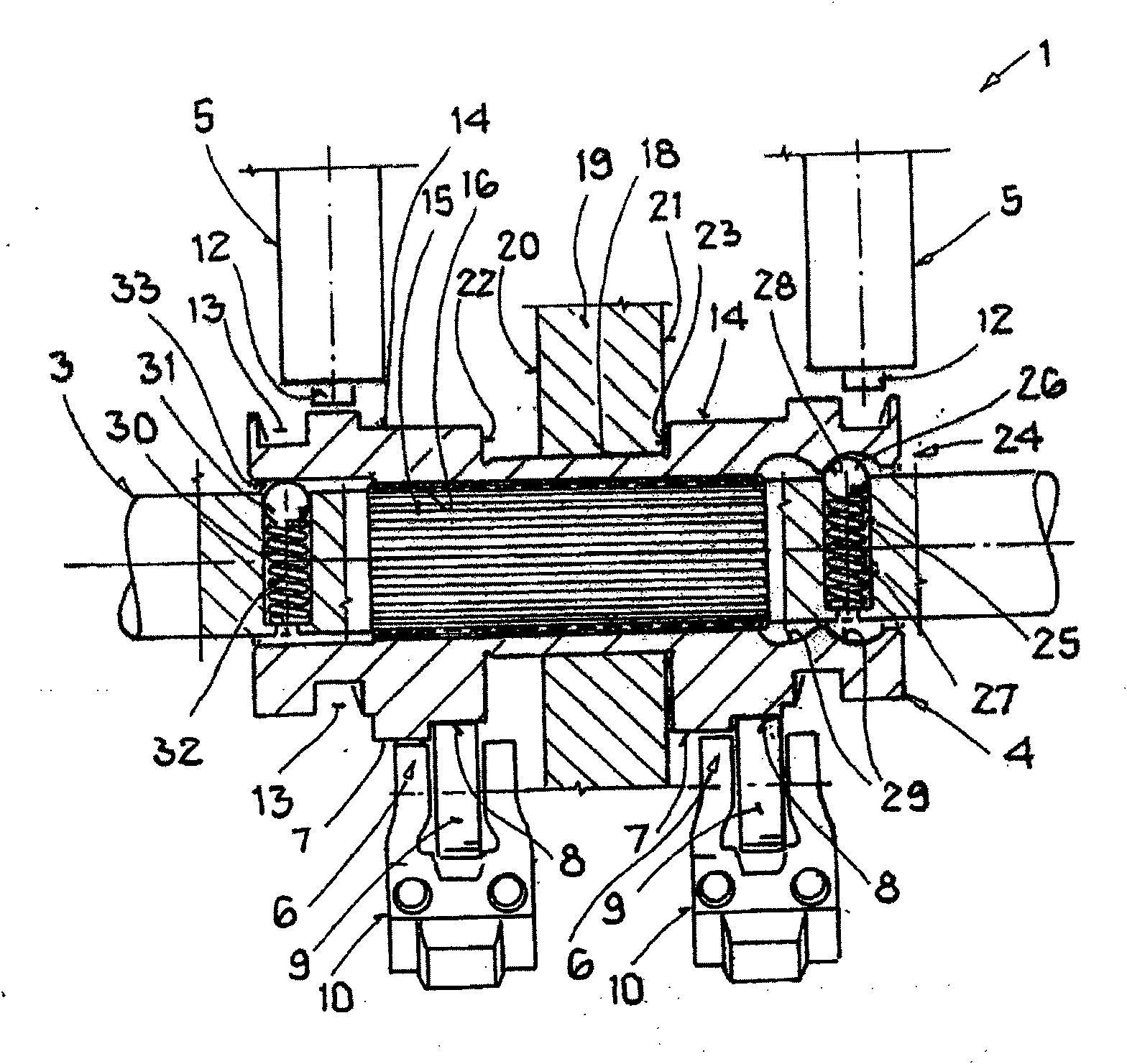

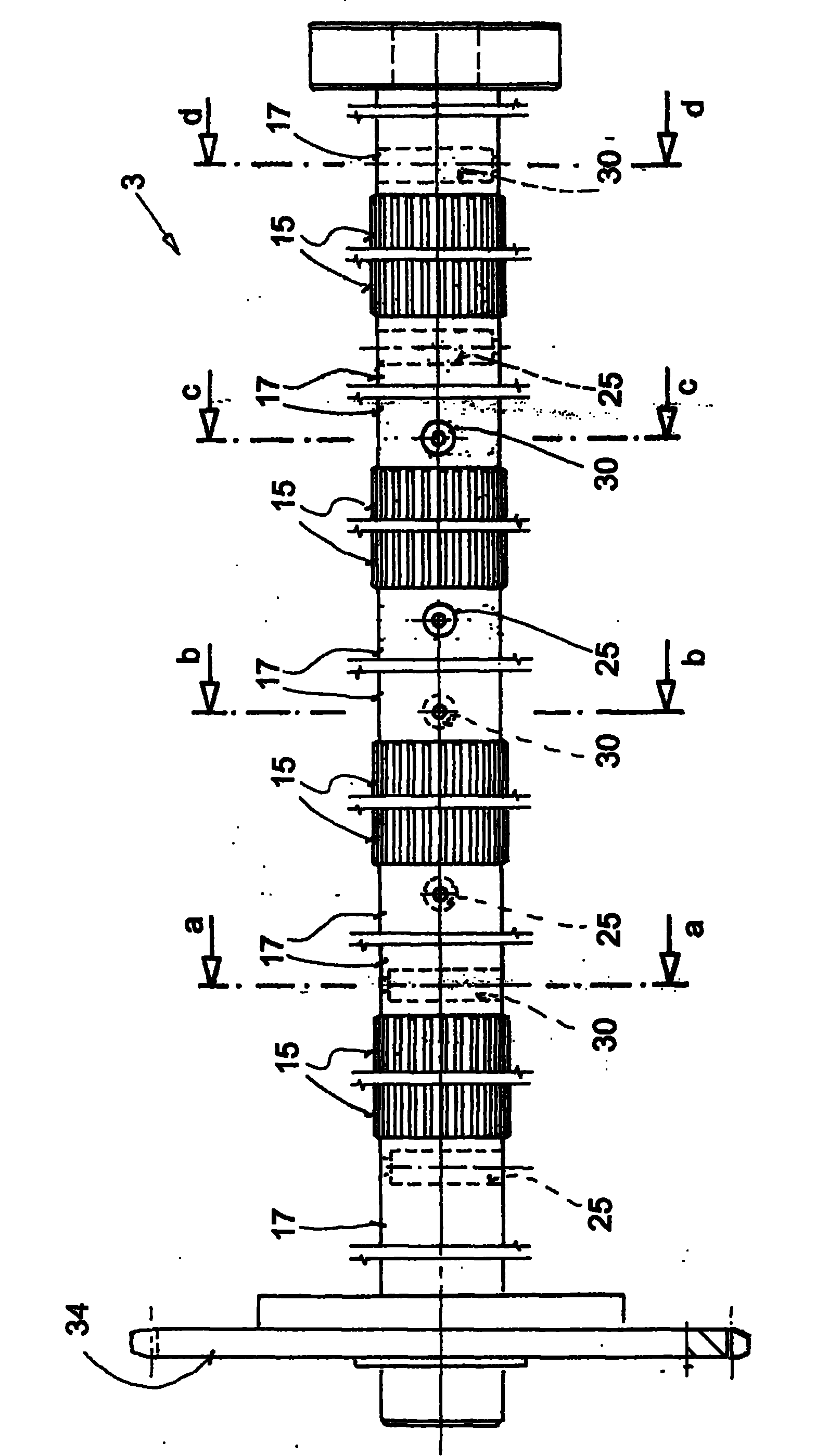

[0018] In the valve train 1 of the paired intake valves 2 for four cylinders of an in-line engine, which is only partially shown in the drawing, the strokes and opening times of the two intake valves 2 per cylinder can be is regulated.

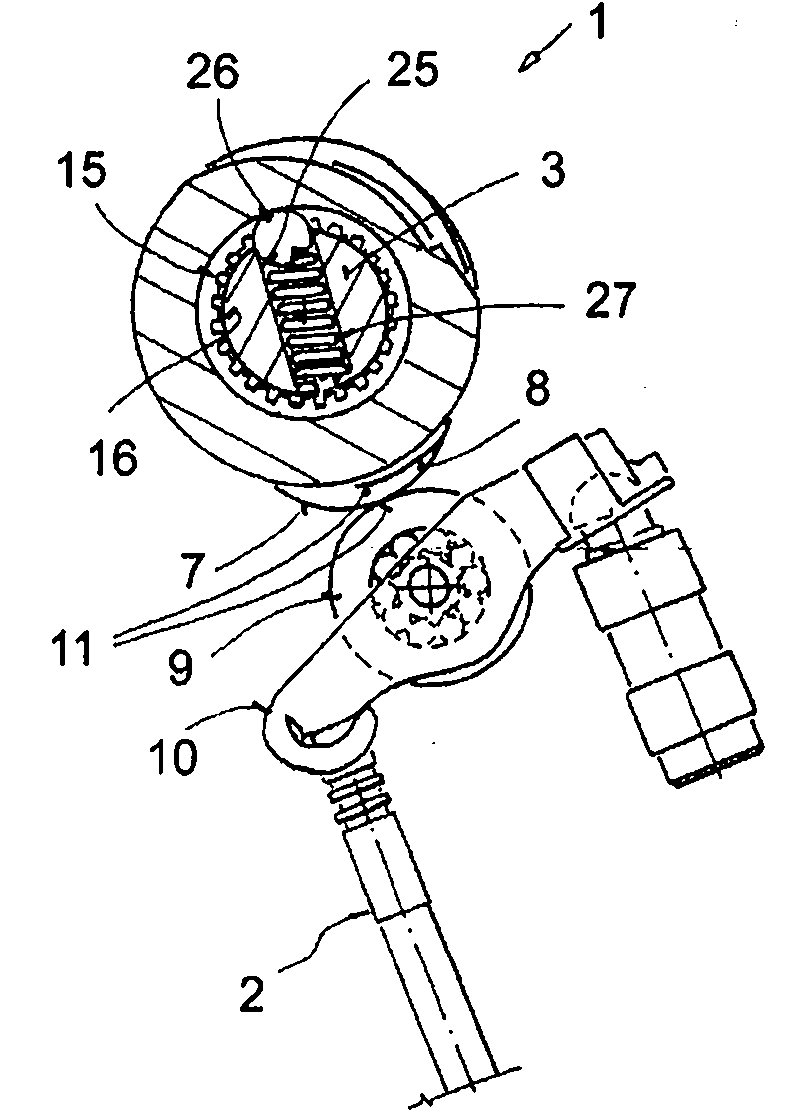

[0019] To this end, the valve train 1 includes a basic camshaft 3 rotatably supported; four cam bearings 4 mounted on the basic camshaft 3 in such a way that they cannot rotate relative to each other but can move axially, figure 1 One of the cam bearings 4 is shown enlarged in longitudinal section; and two actuators (actuators) 5 are used to move each cam bearing 4 between two defined axial displacement positions to move between.

[0020] The cam bearings 4 each have on their outer circumference two cam pairs 6 arranged axially at a distance from one another, wherein each cam pair 6 comprises two cams 7 , 8 . Such as figure 1 As shown most clearly in FIGS. 3 and 3 , each of the two cam pairs 6 interacts with a roller 9 of a pivotably mounte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com