Small-sized food processor

A food processor and food processing technology, applied in the field of kitchen utensils, can solve problems such as inconvenience of operation, achieve the effect of convenient operation mode and increase transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

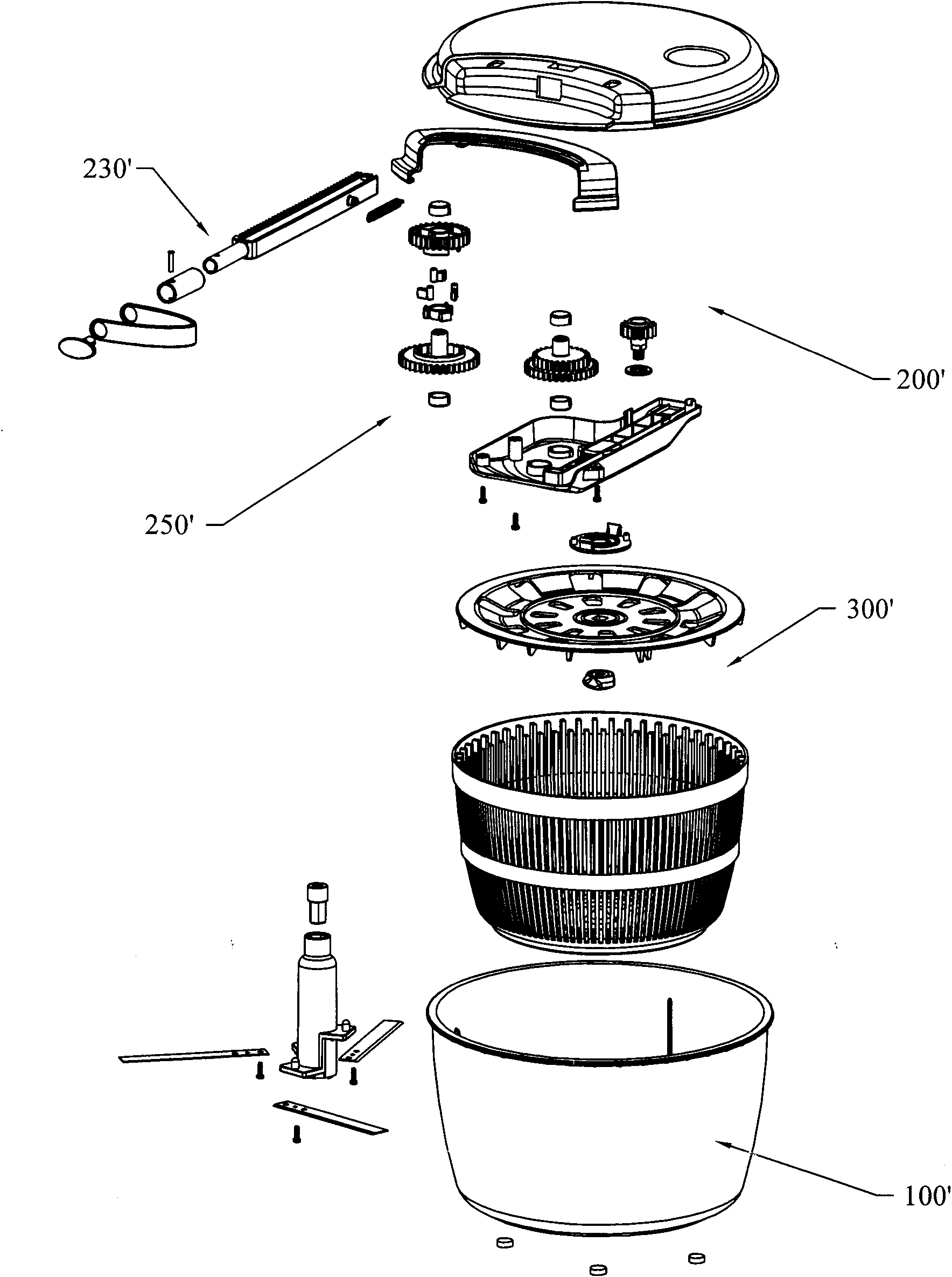

[0045] Such as figure 1 As shown, in the first embodiment of the small food processor of the present invention, the small food processor includes a container 100', a container lid assembly 200' and a food processing assembly 300 disposed in the container 100'. Wherein, the container lid assembly 200' includes a lid body covering the opening of the container 100', a pull rod assembly 230' arranged on the top of the lid body, and a transmission mechanism 250' arranged in the lid body. The pull rod assembly 230' drives the food processing assembly 300 to rotate relative to the container 100' through the transmission mechanism 250', and uses the rotation of the food processing assembly 300 relative to the container 100' to perform dehydration, cutting or stirring of food.

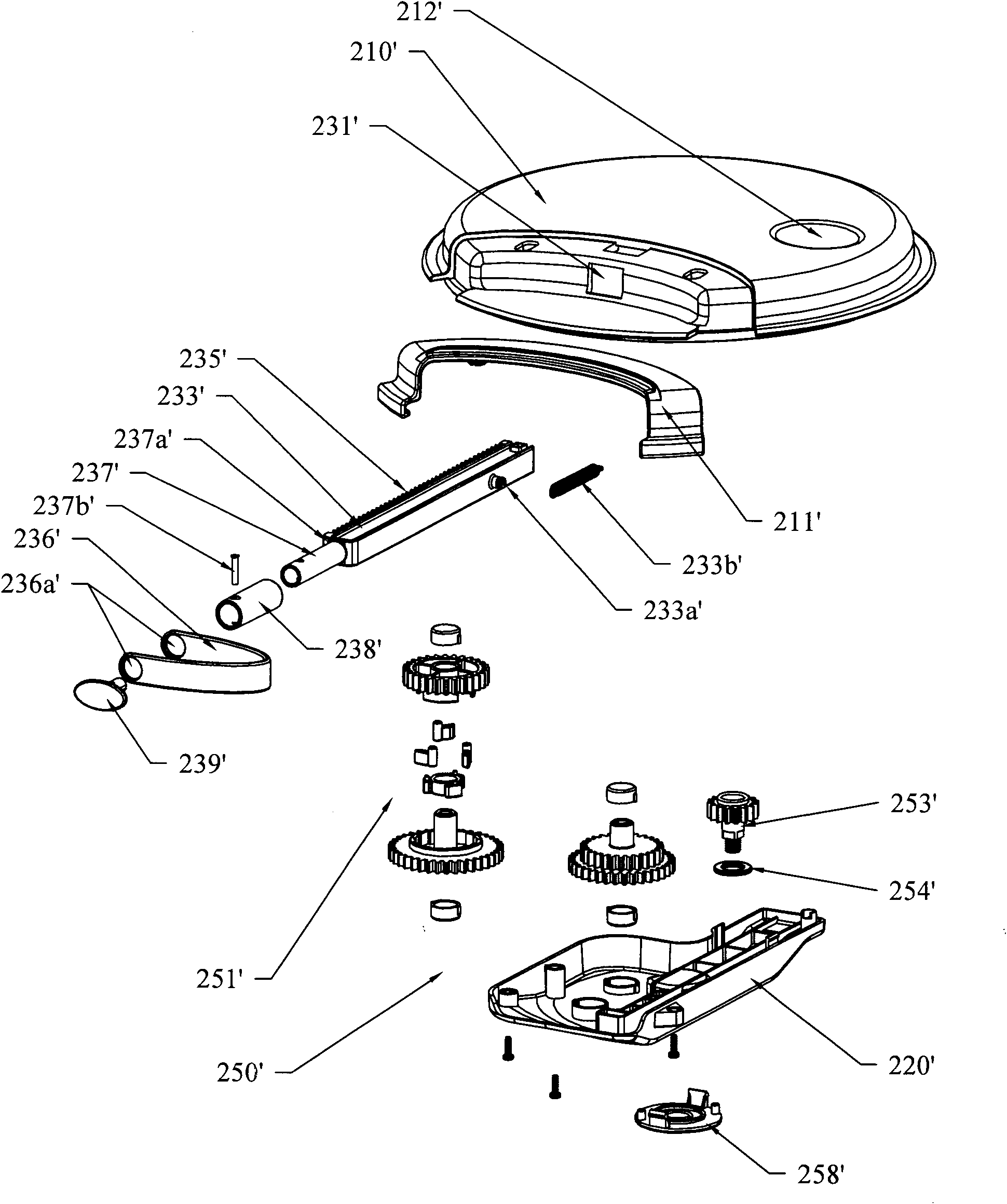

[0046] Such as figure 2 , 2aAs shown, in this embodiment, the cover body is composed of an upper shell 210' and a lower shell 220', and the upper shell 210' and the lower shell 220' are fixedly connected tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com