Electric heat constant-temperature chemical reaction pot

A chemical reaction, constant temperature technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc. Easy to operate, easy to take out samples, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

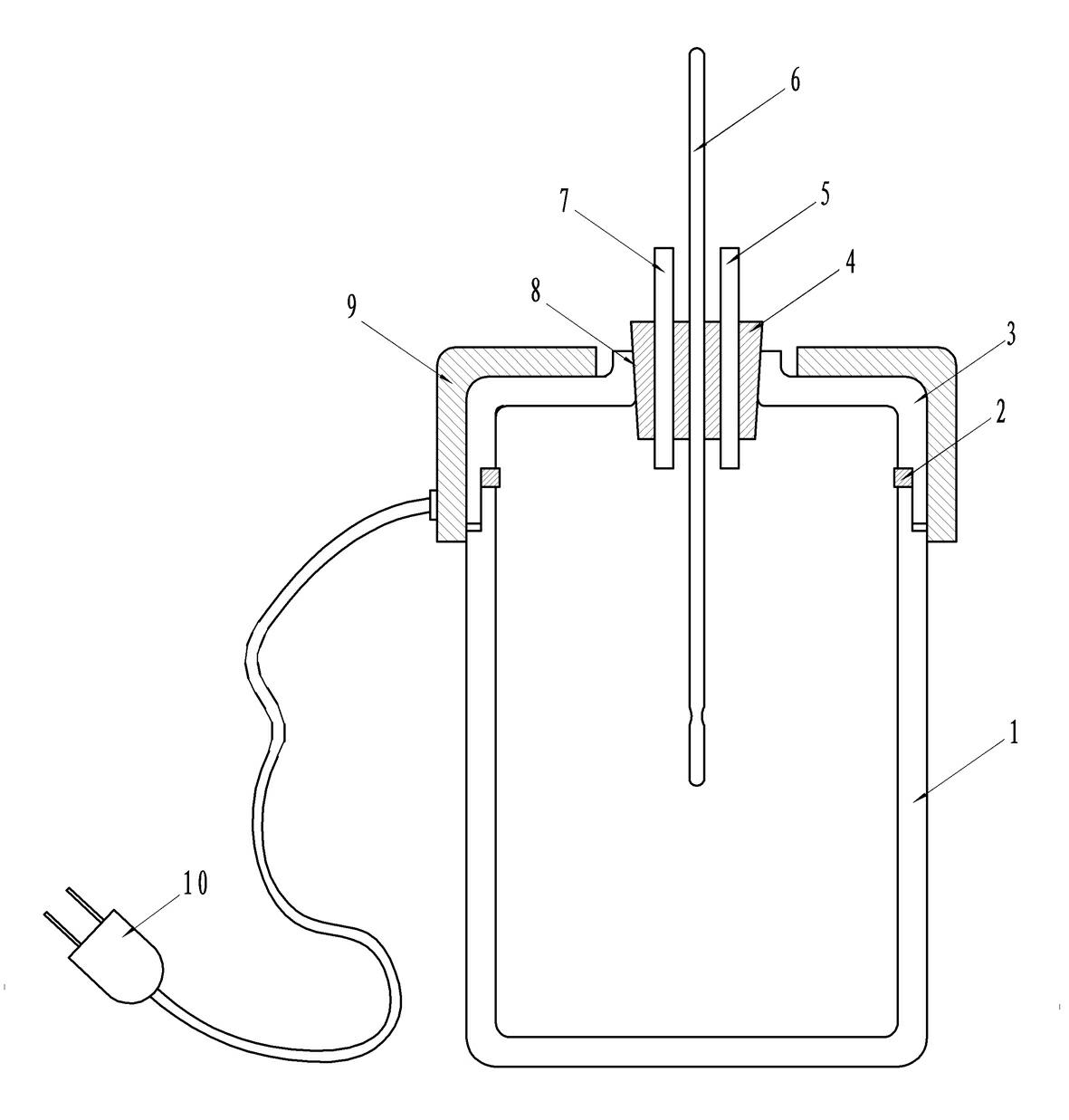

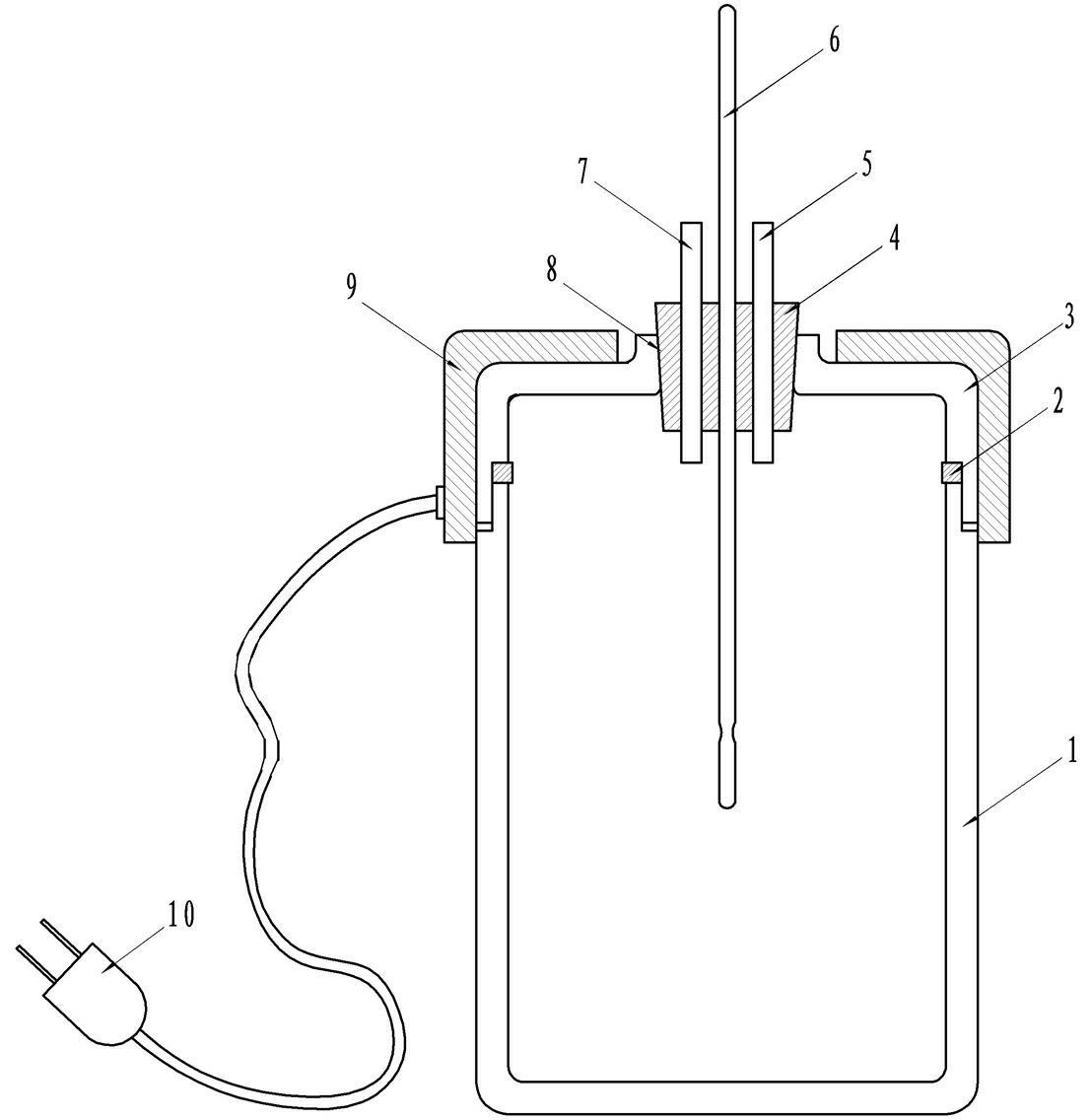

[0020] Refer to attached figure 1 , The electrothermal constant temperature chemical reaction tank includes a stainless steel vacuum insulation tank body 1, a stainless steel vacuum cover 3, a rubber stopper 4, a thermometer 6, a feeding pipe 5, a ventilation pipe 7, and an external heating device 9. The middle part of the stainless steel vacuum upper cover 3 is provided with a rubber stopper installation hole 8, and the rubber stopper installation hole 8 is equipped with a rubber stopper 4. The stainless steel vacuum upper cover 3 is installed on the upper part of the stainless steel vacuum insulation tank body 1, and the stainless steel vacuum upper cover 3 and the stainless steel vacuum Sealing rubber rings 2 are installed between the insulation tanks 1, and an external heating device 9 is installed on the stainless steel vacuum upper cover 3. The rubber stopper 4 is provided with a ventilation hole, a feeding hole, a thermometer jack, etc., and the ventilation hole, the fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com