Tail safety brake device of motor vehicle

A technology for safe braking and motor vehicles, applied in the direction of brakes, braking components, vehicle parts, etc., can solve the problems of long emergency braking distance, achieve the effects of shortening braking distance, convenient disassembly and assembly, and reducing traffic safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

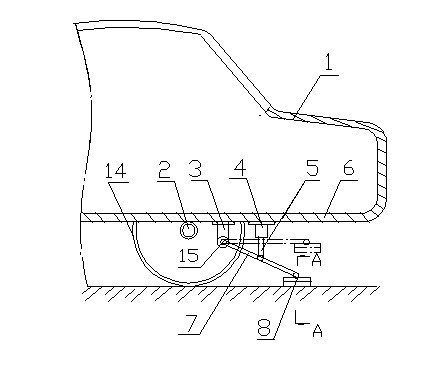

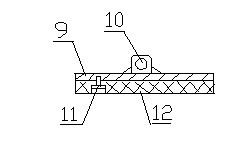

[0014] Example 1, in figure 1 with figure 2 Among them, the safety braking device at the rear of the motor vehicle includes a support 3, a pressure rod 7, a brake plate 8 and an ejector rod 5, and the support 3 is fixed on the rear bottom plate at the middle position near the rear of the rear axle 2 of the rear part 1 of the trolley 6, one end of the pressure rod 7 is movably connected with the support by a hinge shaft 15, the other end of the pressure rod is movably connected with the middle position of the support plate 9 on the brake plate 8 through the joint 10, and one end of the ejector rod 5 is movable in the middle of the pressure rod The other end of the ejector rod is connected to the oil cylinder 4, and the oil cylinder is fixed on the rear bottom plate. The brake plate includes a support plate 9 that is movably connected with the pressure rod and fixed on the support plate with several spaced apart screw rods 11. wear-resistant plate 12, the length of the support...

Embodiment 2

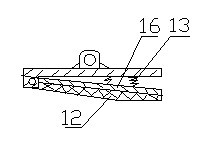

[0015] Example 2, in figure 1 with image 3 Among them, except that the structure of the brake plate is different from that of Example 1, other structures of Example 2 are the same as those of Example 1. The brake plate includes a support plate 9, a wear plate 12 and a lining plate 16, and the wear plate The plate is fixed on the liner with a screw rod and arranged obliquely. One end of the liner is movably connected with the support plate. A spring 13 is arranged between the liner and the support plate. The other end of the liner is separated from the support plate. The wear plate and the support plate are separated. The liner is arranged at an angle less than 15°, and the springs are arranged in one or two rows.

Embodiment 3

[0016] Example 3, in figure 1 with Figure 4 Among them, because the road surface of expressways, especially some provincial roads or national roads is not very smooth, in order to improve the auxiliary braking capability of the rear safety brake device of the present invention, except that the structure of the brake plate is the same as that of Embodiment 1 and Embodiment 1. 2, the other structure of embodiment 3 is the same as that of embodiment 1. The brake plate includes a support plate and a wear plate, and the wear plate 12 is composed of several small wear plates, and each small wear plate The springs 13 are fixedly connected with the support plate 9 respectively, and the wear-resistant plates are arranged longitudinally along the bottom plate of the tail,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com