Extruding and extending device for horizontal loading drainage solidifying soft soil reinforcement and construction method thereof

A technology of drainage consolidation and horizontal loading, which is applied in the field of soft soil drainage consolidation and reinforcement method and squeeze-expanding device, can solve the problems of large post-construction settlement, long construction period, limited effective reinforcement depth, etc. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

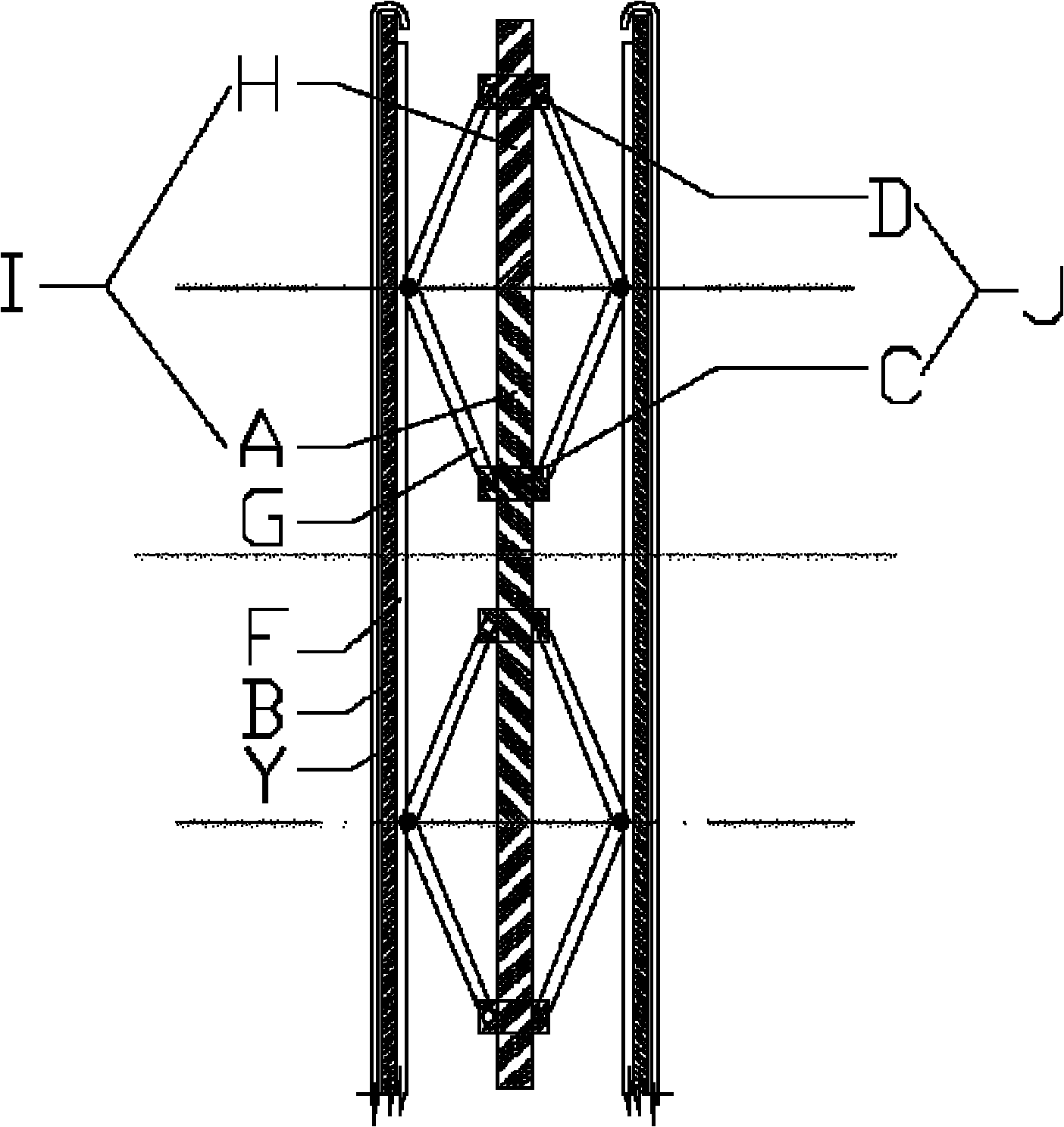

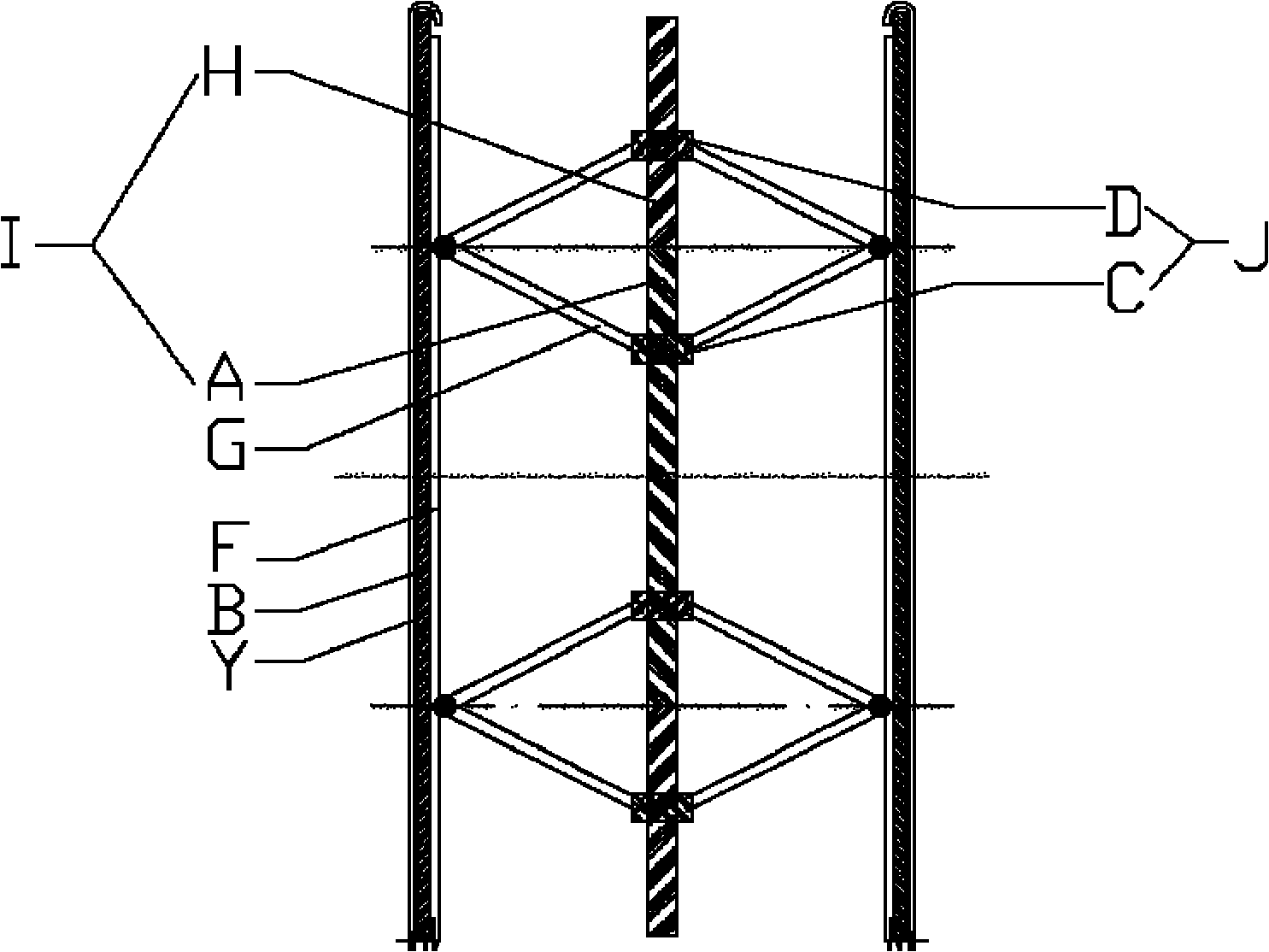

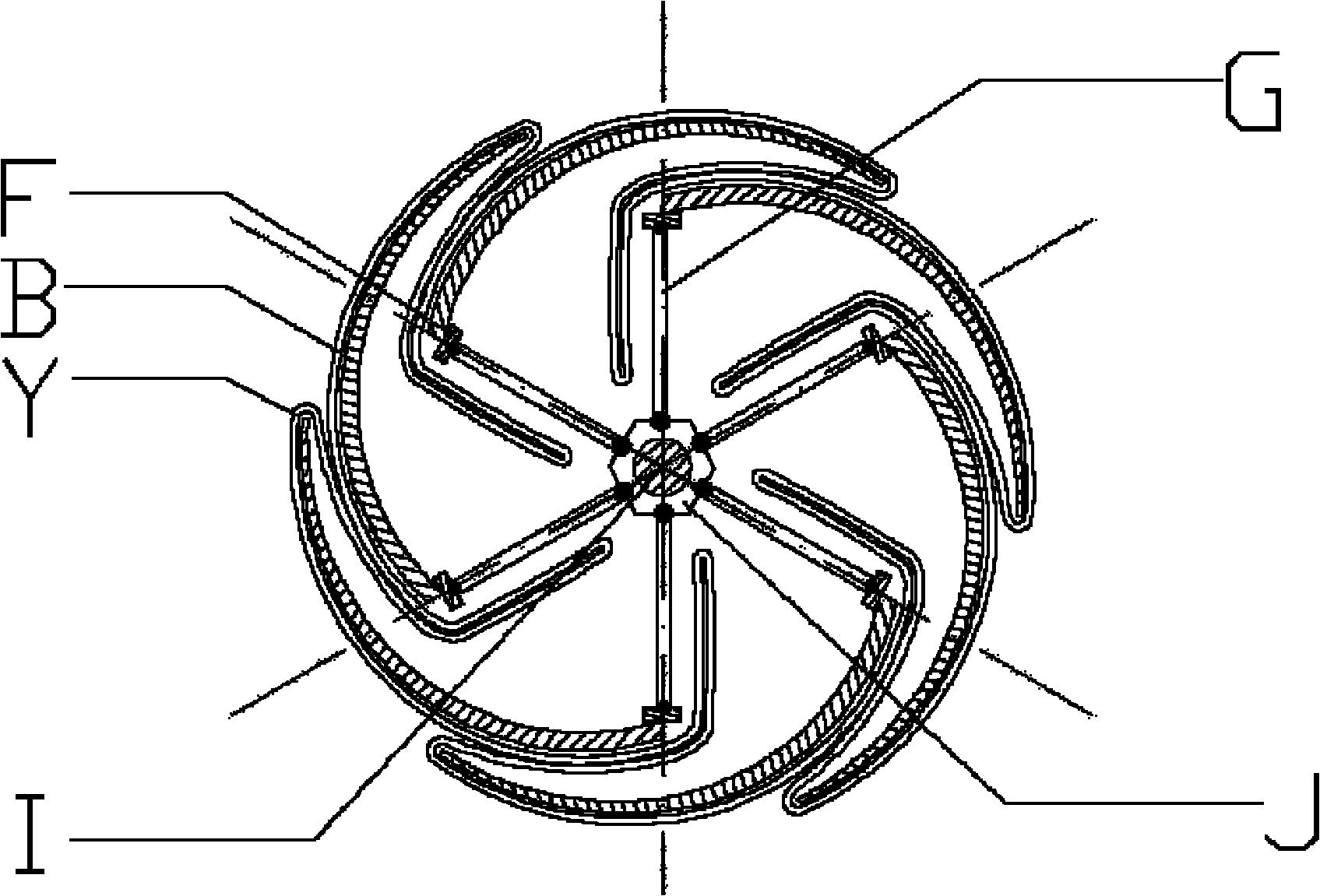

[0063] The soil layer of the project site is flow-plastic muddy clay. The extruder is made of aluminum alloy, the extruder adopts the whole plate method, and the expansion blade B adopts such as Figure 3a In the porous plate type shown, the holes 1 on the porous plate are evenly distributed, the permeable filter membrane Y is a wire mesh, and the permeable filter membrane Y is only welded to cover the hole 1 of the expanded blade B, as Figure 4b shown. The number of support rod pairs G and the support beams F and expansion blades B connected thereto is six. When the expander is in a contracted state, the diameter of the expander is 80mm, the diameter after expansion is 150mm, and the length of the expander is 10m. The distance between the expanders is 80cm, and the expanders in the shrinking state are pressed into the soil by static pressure. Rotate the central screw I of the extruder to expand the extruder to a diameter of 150mm by 2mm each time and once every 4 hours; d...

Embodiment 2

[0065]The soil layer of the project site is flow-plastic silty clay. The extruder is made of low-alloy carbon steel, and the number of support rod pairs G and connected support beams F and expansion blades B is 8. The extruder uses Figure 4c The half-plate form shown, that is, after the expansion blade B is fully expanded, one end of the expansion blade B is still connected to the support beam F, and the other end is a free end suspended in the air. The expansion blade B is used as follows: Figure 3b In the form of the grid shown, the grid form is a grid 2 evenly distributed in strips. The permeable filter membrane Y is a non-woven fabric reinforced with polymer fiber braided strips, and is made into a complete cylinder to cover the periphery of all expansion blades B of the expander and the soil layer in the gap between two adjacent expansion blades B The pressure is supported by the permeable membrane Y. The diameter of the expander is 100mm in the contracted state, and...

Embodiment 3

[0067] The soil layer of the project site is flow-plastic muddy silty clay. The extruder is made of high-strength engineering plastics, and the extruder is made of Figure 4d The form shown is the form without plates, the number of support rods G and the number of support beams F connected to them is 8; the permeable filter membrane Y is made of polymer fiber woven cloth, the diameter of the expander is 80mm in the contracted state, and the diameter after expansion is 80mm. 300mm, the design pile length is 20m. The space between the extruder 3 and the plastic drainage board 4 is arranged using Figure 5a Arrangement mode (triangular arrangement), the distance between the expanders is 300cm, and the expanders in the shrinking state are pressed into the soil by static pressure. Rotate the central screw of the extruder to expand the extruder to a diameter of 300mm by 5mm each time and once every 3 hours, drain the water in the pile hole formed by the extruder, and pour fluid ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com