Horizontal winding machine

A horizontal winding machine and coiler technology, which is used in the manufacture of coaxial cables, insulation of conductors/cables, etc., can solve the problems that affect the production efficiency of ultra-fine coaxial cables, the unsteady wire pay-off process, and the winding machine Line speed limit and other issues, to achieve the effect of adjustable row spacing, low equipment cost and good winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

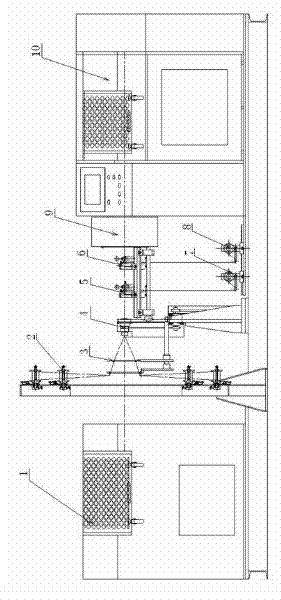

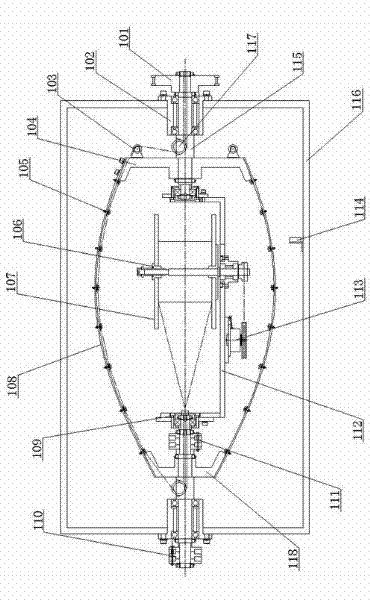

[0031] see figure 1 , a kind of horizontal winding machine that the present invention relates to, it comprises the untwisting pay-off machine 1 that is arranged in sequence along the horizontal direction, plain wire pay-off machine 2, line-incoming branch board 3, die hole 4, conductor taping device 5 , insulation taping device 6, drawing machine 9 and coiler 10, described untwisting pay-off machine 1, plain wire pay-off machine 2, incoming line splitter plate 3, die eye 4, conductor taping device 5, insulation The center lines of the tape wrapping device 6, the drawing machine 9 and the coiler 10 are on the same horizontal line, the first tape unwinding device 7 is arranged below the conductor tape wrapping device 5, and the second tape unwinding device 7 is arranged below the insulating tape wrapping device 6. Tape unwinding device 8. The core wire of the ultra-fine coaxial line is rotated under the action of the drawing machine 9, and the untwisted pay-off machine 1 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com