Gripper for retaining flat components such as a silicon-based wafer in a nearly contactless way

A non-contact, chip technology, applied in the direction of electrical components, conveyor objects, semiconductor/solid-state device manufacturing, etc., can solve problems such as surface damage, permanent damage, chip deformation, etc., and achieve the effect of avoiding unintentional skewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

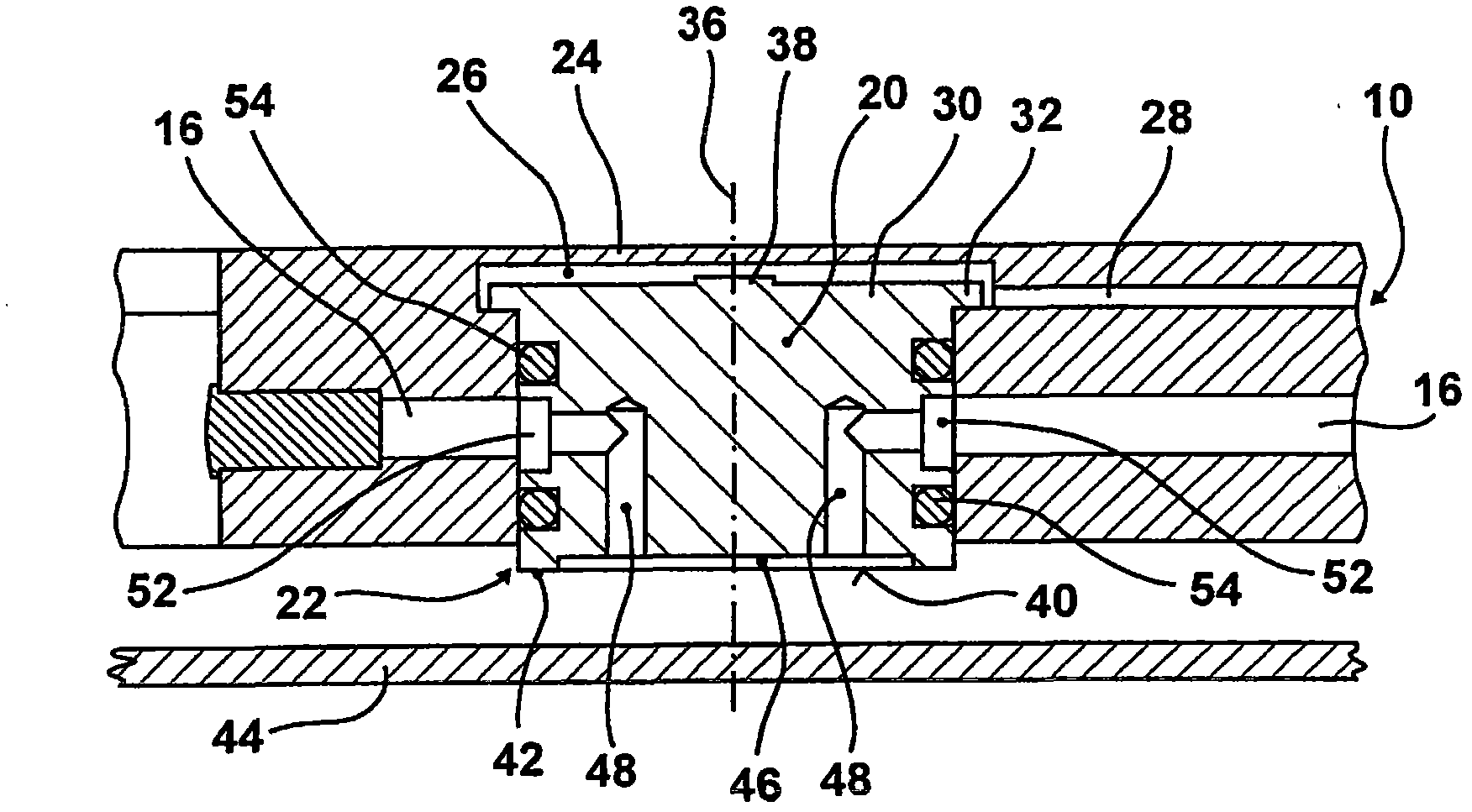

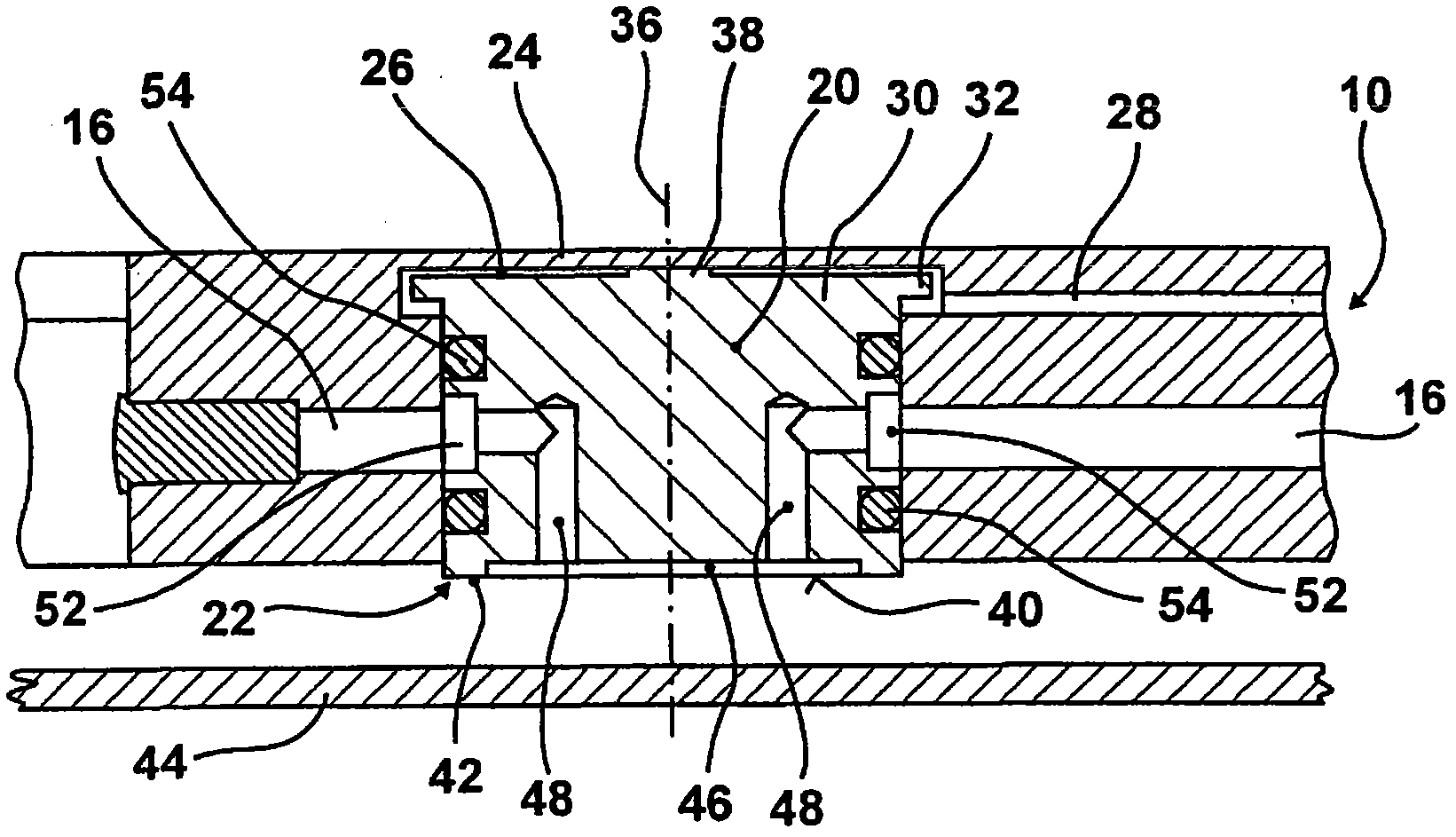

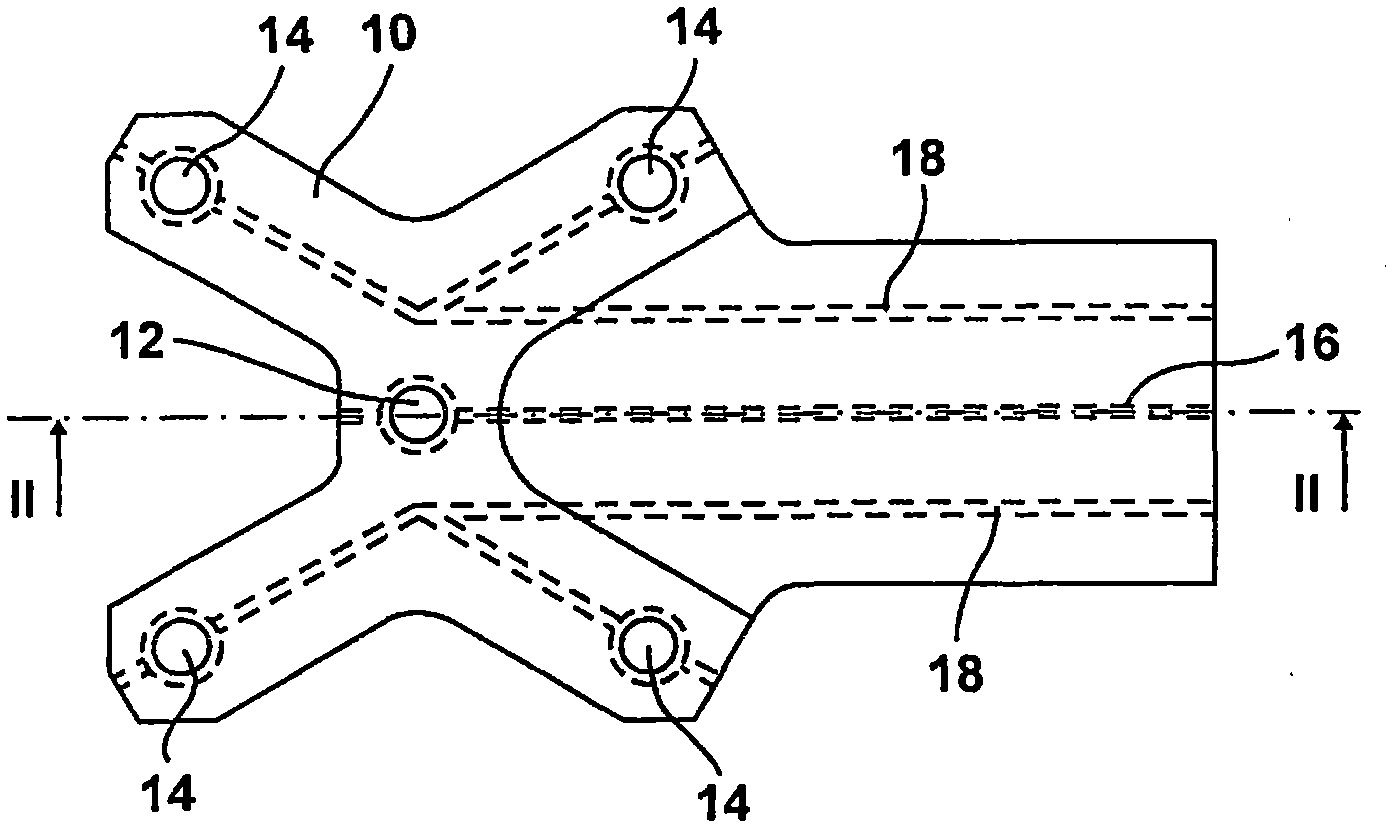

[0050] Figure 1 to Figure 3 An example of an embodiment of a gripper according to the invention is shown in , which can be fastened to a robot arm or to a linear operating system. The holder comprises a support device 10 with five suction points, wherein a central suction point 12 is arranged in the center and four side suction points are respectively evenly spaced (equidistantly) around the central suction point. Suction part 14. The four side suction points 14 are likewise arranged equidistantly from one another. The central suction point 12 is connected to a first suction channel 16 , while the side suction point 14 is connected to a side suction channel 18 .

[0051] A negative pressure can be applied to the side suction channel 18 independently of the suction channel 16 . In this way, the side suction point 14 and the central suction point 12 can be controlled independently, whereby the central suction point 12 can be supplied with negative pressure even without negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com